Preparation method for colorless transparent high-temperature-resistant polyimide nanometer composite film

A polyimide and nanocomposite technology, which is applied in the field of preparation of colorless, transparent and high temperature resistant polyimide nanocomposite films, can solve the problems of low thermal expansion coefficient, unmentioned film transmittance and glass transition temperature, etc. , to achieve the effect of high light transmittance, good optical performance and high dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A method for preparing a colorless, transparent, high-temperature-resistant polyimide nanocomposite film, comprising:

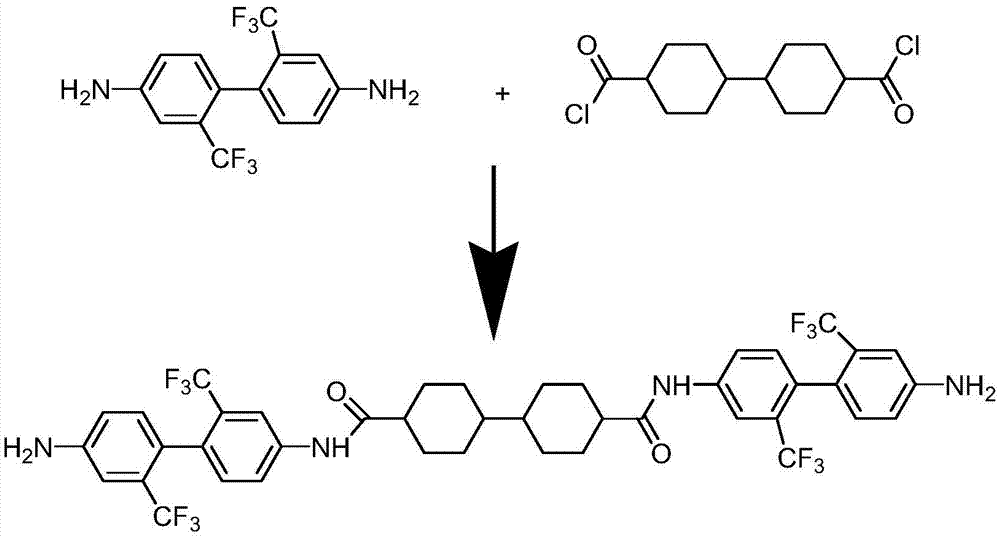

[0034] (1) Reaction of 4,4-bicyclohexyl dicarboxylic acid chloride (BCCL) and hexafluoromethylbenzidinediamine (TFDB) in an organic solvent to obtain a semi-aromatic fluorinated diamine precursor ADB (such as figure 1 shown);

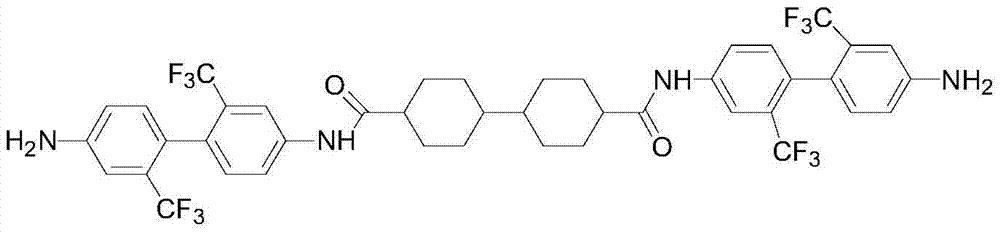

[0035] The semi-aromatic fluorinated diamine precursor ADB structural formula is:

[0036]

[0037] (2) The semi-aromatic fluorinated diamine precursor ADB is mixed with hexafluoromethylbenzidine diamine (TFDB), 4,4'-(hexafluoroisopropylene) diphthalic anhydride (6FDA), 3,3, 4,4-biphenyldianhydride (BPDA) monomer copolymerization; or the semi-aromatic fluorinated diamine precursor ADB and hexafluoromethylbenzidinediamine (TFDB), 4,4'-(hexafluoroiso Propylene) diphthalic anhydride (6FDA), hydrogenated 3,3,4,4-biphenyl dianhydride (HBPDA) monomer copolymerization to obtain polyamic acid PAA1 precursor;

[0038] (3) reacting ...

Embodiment 1

[0055] Put 32.0g of hexafluoromethylbenzidinediamine (TFDB), 8.7g of pyridine and 800ml of dimethylacetamide (DMAc) into the reaction flask at room temperature, stir well to make it dissolve completely, then slowly add 14.0g of 4,4-bicyclohexyl dicarboxylic acid chloride, and the mixed solution was maintained under nitrogen protection for 4 hours. After the reaction is finished, pour the mixed solution into 8L of 10% sodium chloride solution, stand at 0°C for 12 hours, wash and filter with water to obtain a white powder, dry the powder at 90°C for 9 hours under the protection of nitrogen to obtain the ADB front body with a yield of about 94%.

[0056] Under the condition of nitrogen protection, 9g of ADB precursor and 100ml of N-methylpyrrolidone were added into the reaction flask, stirred thoroughly at 80°C, and then 6.2g of hexafluoromethylbenzidinediamine (TFDB) was added after the ADB monomer was completely dissolved. Then the reaction temperature was lowered to 20°C, and...

Embodiment 2

[0060] Under the condition of nitrogen protection, 9g of ADB precursor and 100ml of N-methylpyrrolidone were added into the reaction flask, stirred thoroughly at 80°C, and then 6.2g of hexafluoromethylbenzidinediamine (TFDB) was added after the ADB monomer was completely dissolved. Then the reaction temperature was lowered to 20°C, and then 1.5 g of 4,4'-(hexafluoroisopropene) diphthalic anhydride (6FDA) and 9.0 g of hydrogenated 3,3,4,4-biphenyl dianhydride (HBPDA) were added slowly Into the above mixed solution containing ADB and TFDB. The reaction was maintained at 20° C. for 48 hours, and after the reaction was completed, 20 wt % of an anhydride-terminated polyamic acid solution PAA1 precursor was obtained. Subsequently, 1.3ml of silane coupling agent 3, aminotrimethoxysilane (APTMS) was slowly added to the above-mentioned polyamic acid solution precursor and maintained for reaction for 6 hours, and the polyamic acid PAA2 terminated by the silane coupling agent was obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com