Method for preparing permanent magnet strontium ferrite by utilizing iron oxide red

A technology of iron oxide red and strontium ferrite, which is applied in the field of comprehensive resource utilization and material synthesis, can solve the problems of high production temperature and achieve the effects of uniform composition, low temperature and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

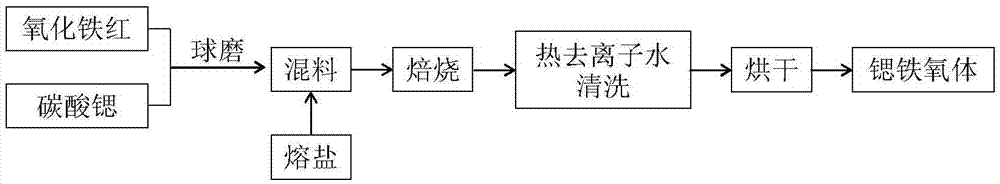

[0027] The method for preparing permanent magnet strontium ferrite by using red iron oxide comprises the following steps:

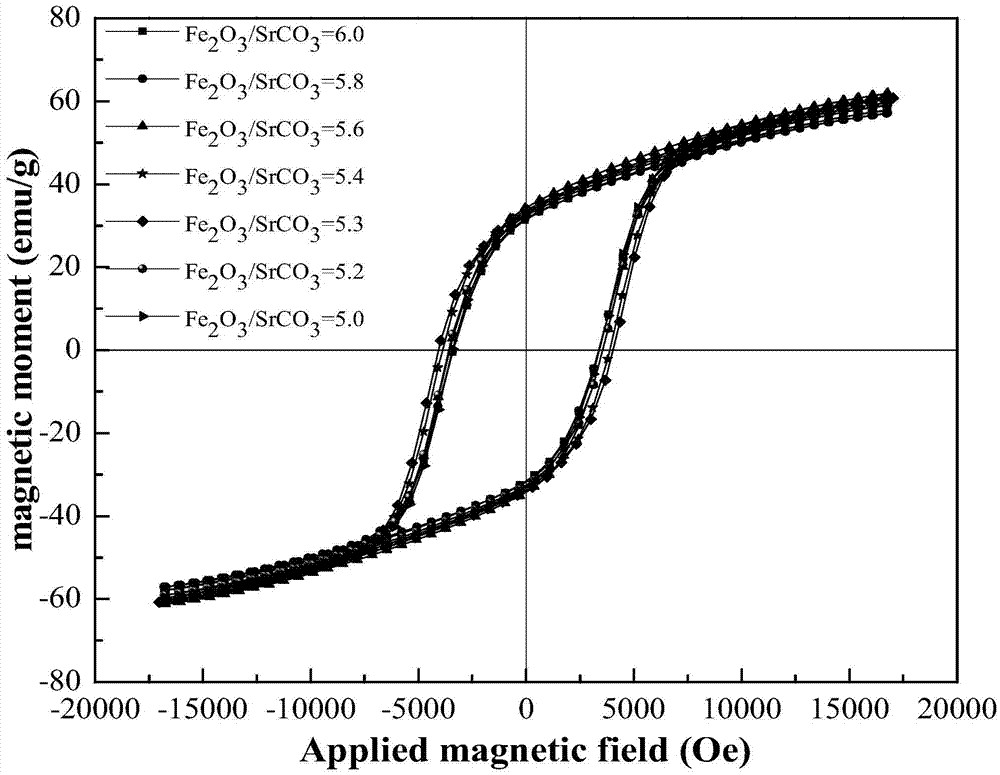

[0028] Step 1: After the iron oxide red and strontium carbonate obtained by rolling steel scale are mixed according to the molar ratio in Table 1, ball milling is carried out with a planetary ball mill. The rotating speed is 250r / min, and the particle size of the obtained material is ≤500nm;

[0029] Step 2: The ball-milled material and NaCl-KCl eutectic salt are mixed uniformly at a mass ratio of 1:1, put into a corundum crucible, and calcined at 1100°C for 2 hours in a muffle furnace;

[0030] Step 3: Wash and filter the reacted material with deionized water at 80°C to 120°C until all the molten salts are washed away, and then dry the obtained product in a vacuum drying oven at 80°C for 10 hours to obtain permanent magnet strontium ferrite.

[0031] The magnetic properties index of the permanent magnet strontium ferrite prepared by the present embodim...

Embodiment 2

[0037] The method for preparing permanent magnet strontium ferrite by using red iron oxide comprises the following steps:

[0038] Step 1: Red iron oxide and strontium carbonate obtained by rolling steel scale are mixed according to the molar ratio of 5.3:1. After batching, the planetary ball mill is used for ball milling. The mass ratio of ball to material is 9:1, and the ball milling time is 5 hours. The rotating speed is 300r / min, and the particle size of the obtained material is ≤500nm;

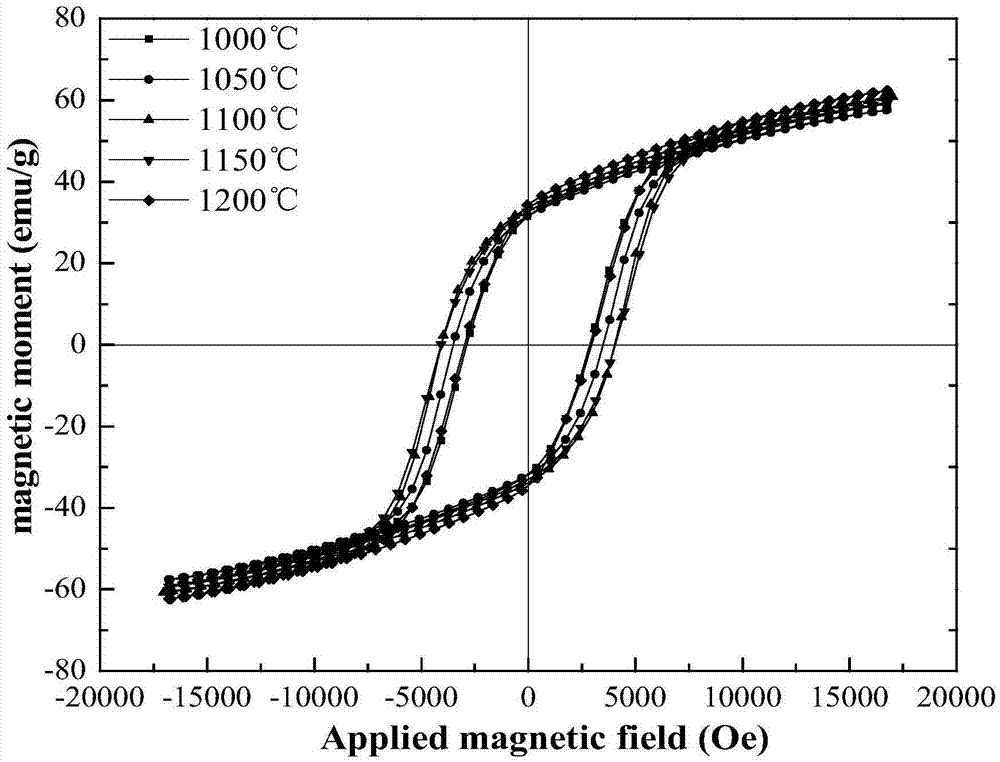

[0039] Step 2: The ball-milled material and NaCl-KCl molten salt are mixed evenly in a mass ratio of 1:1, put into a corundum crucible, and calcined at the temperature in Table 2 for 2 hours in a muffle furnace;

[0040] Step 3: wash and filter the reacted material with 80°C deionized water until all the molten salts are washed away, and then dry the material in a vacuum drying oven at 80°C for 16 hours to obtain permanent magnet strontium ferrite.

[0041] The magnetic properties of the s...

Embodiment 3

[0046] The method for preparing permanent magnet strontium ferrite by using red iron oxide comprises the following steps:

[0047] Step 1: The red iron oxide and strontium carbonate obtained by rolling steel scale are mixed according to the molar ratio of 5.3:1. After batching, the planetary ball mill is used for ball milling. The mass ratio of ball to material is 12:1. The rotating speed is 200r / min, and the particle size of the obtained material is ≤500nm;

[0048] Step 2: The ball-milled material and the molten salt in Table 3 are mixed evenly at a mass ratio of 10:1, put into a corundum crucible, and calcined at a temperature of 1100° C. for 2 hours in a muffle furnace;

[0049] Step 3: wash and filter the reacted material with deionized water at 100°C until all the molten salts are washed away, and then dry the material in a vacuum oven at 100°C for 8 hours to obtain permanent magnet strontium ferrite.

[0050] The magnetic properties of the permanent magnet strontium fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com