High-voltage direct current power supply applied to dust removal system

A high-voltage DC power supply and dust removal system technology, applied in the direction of irreversible AC power input conversion to DC power output, high-efficiency power electronic conversion, electrical components, etc., can solve the problem that the output secondary voltage fluctuates greatly, which affects the dust collection efficiency and is reliable. Poor performance and other issues, to achieve the effect of small switching loss, reduced volume, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

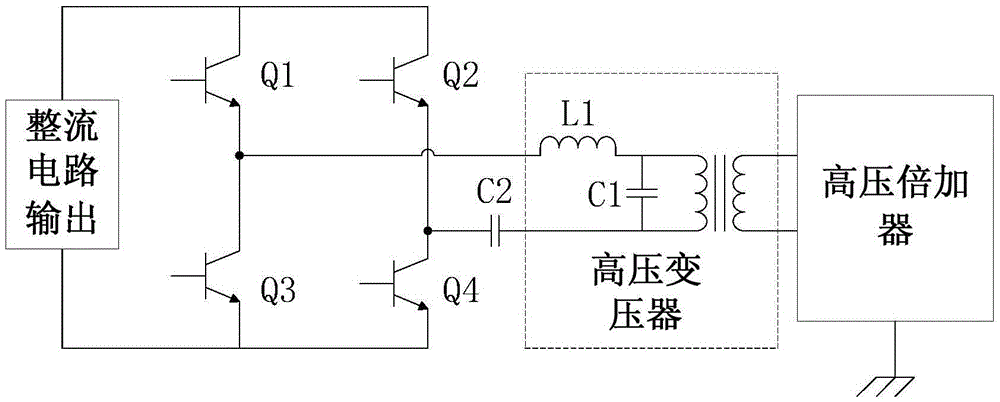

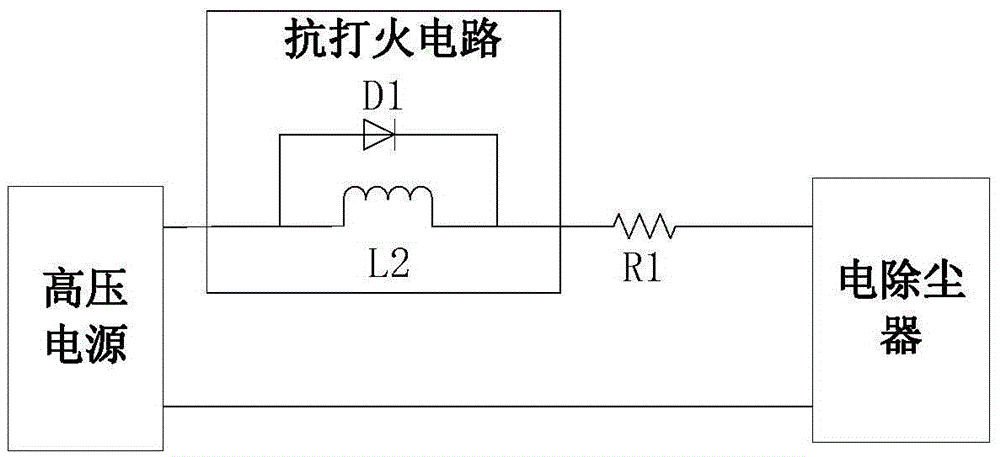

[0018] Such as figure 1 As shown, the miniaturized high-voltage direct current power supply device applied to the dust removal system in the present invention is powered by three-phase power frequency alternating current, which is converted into direct current through a three-phase input filter and a three-phase uncontrolled full-bridge rectifier circuit, and passed through a high-voltage power supply inverter circuit Inverted into high-frequency 50kHz AC, the AC is then output as 60kV high voltage through high-voltage transformer, voltage doubler rectification, anti-ignition circuit and high-voltage output structure. The three-phase input filter, rectifier circuit, and high-voltage power inverter circuit are installed in a fully metal-shielded converter case. The converter case doubles as a radiator to conduct the heat generated inside the converter to the outside, and a fan is arranged outside the converter case to assist in heat dissipation. The high-voltage transformer, v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com