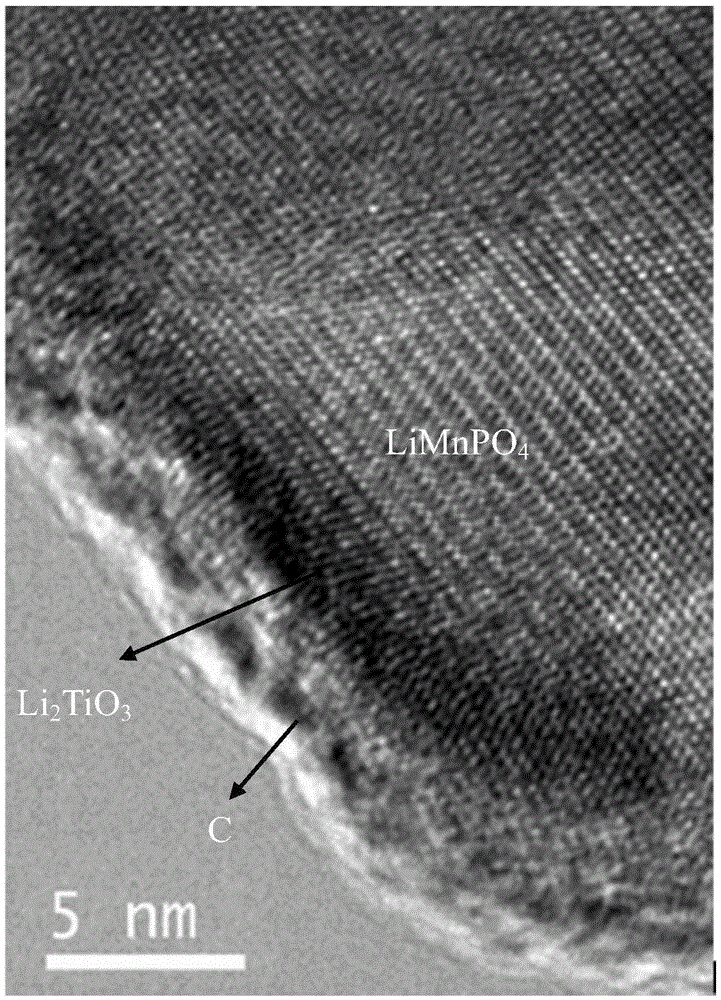

Method for modifying nanometer LiMnPO4/C cathode material coated with lithium ion conductor

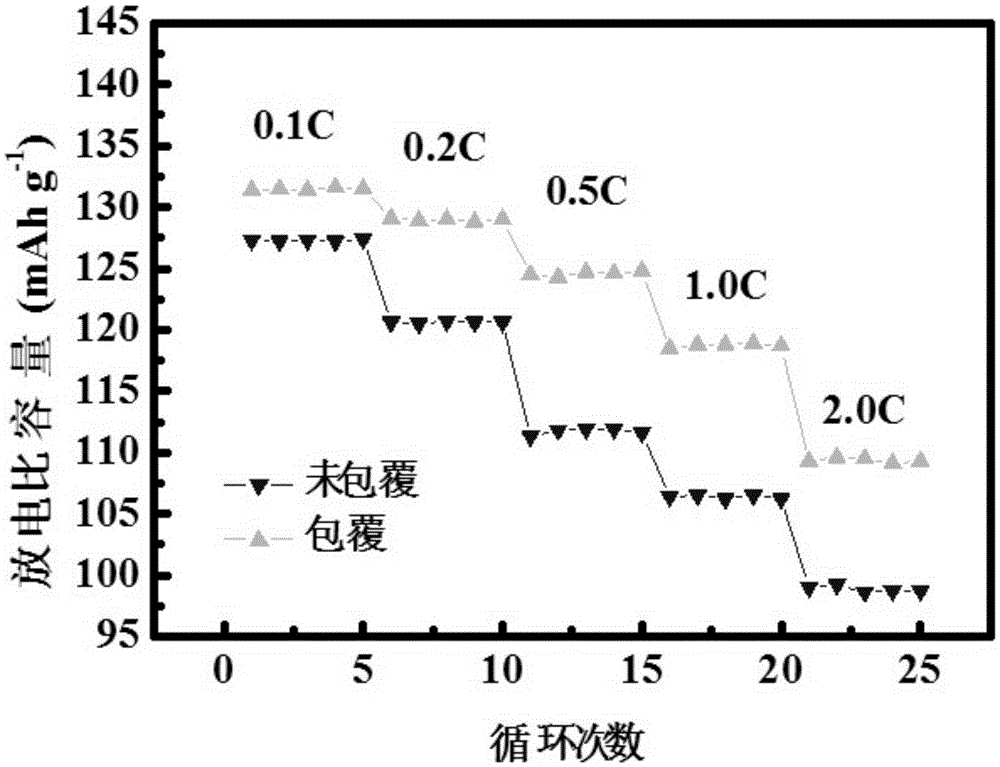

A positive electrode material, lithium ion technology, applied in the field of lithium ion battery positive electrode material preparation, can solve problems such as difficult to control uniformity, complex process, etc., and achieve the effect of easy control of reaction conditions, simple process, and uniform coating layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

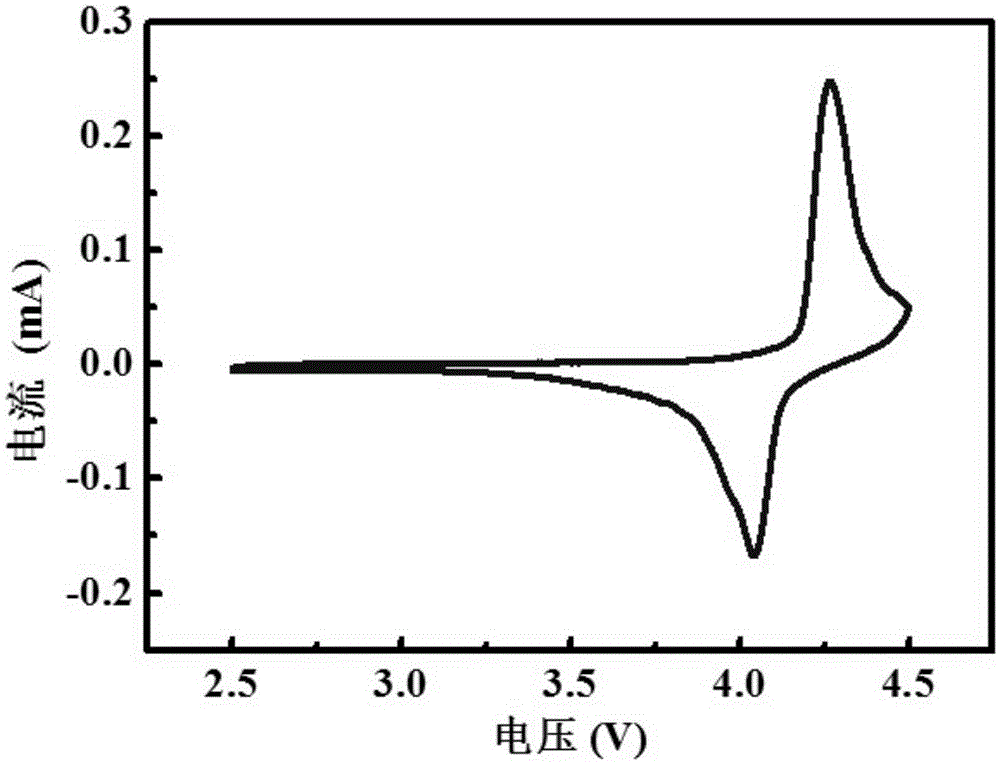

[0034] 0.3molLiOH·H 2 OEG-H 2 O solution was added dropwise to 0.1mol H 3 PO 4 solution, a milky white suspension was obtained, and then 0.1molMnSO was added 4 solution and 10g of glucose, mixed evenly, sealed, and solvothermally reacted at 180°C for 12 hours to obtain the hydroxylated LiMnPO on the surface 4 / C material, wherein control EG in the reactor is 950ml, H 2 O is 50ml. Weigh 5 g of surface hydroxylated LiMnPO 4 / C material, dispersed in 50ml of isopropanol, stirred evenly to obtain a dispersion; then, measure 1.75ml of titanate coupling agent TC-201 and dissolve it in 8ml of isopropanol, stir to form a solution, and stir Add it to the above dispersion under the condition of , then add 5ml of isopropanol to the mixture and stir for 2 hours, then dry it at 60°C; finally mix the dried mixture with 0.068g of lithium carbonate and 1.2g of polyethylene glycol, Under a nitrogen protective atmosphere, calcined at 700 ° C for 2 hours to obtain a lithium ion conductor ...

Embodiment 2

[0037] Take by weighing 3g the surface hydroxylated LiMnPO obtained according to the aforementioned method (embodiment 1) 4 / C material, dispersed in 30mL of absolute ethanol, stirred evenly to obtain a dispersion; then, measure 0.4ml of vanadyl triisopropoxy, added to 6ml of absolute ethanol, stirred evenly to form a solution, and stirred Then, slowly add 6ml of deionized water into the mixture, continue to stir for 2 hours, and then dry it at 85°C; finally mix the dried mixture with 0.6g amylopectin. Under the mixed protective atmosphere of argon-hydrogen (95:5), bake at 650°C for 2 hours to obtain 5% V 2 o 5 Surface-coated LiMnPO 4 / C cathode material.

Embodiment 3

[0039] 0.09molLiOH·H 2 OEG-H 2 O solution was added dropwise to 0.06mol LiH 2 PO 4 solution, a milky white suspension was obtained, and then 0.06molMnAc was added 2 solution and 6g of glucose, mixed evenly, sealed, and solvothermally reacted at 200 °C for 4 hours to obtain LiMnPO rich in hydroxyl groups on the surface 4 / C material, wherein control EG in the reactor is 540ml, H 2 O is 60ml. Weigh 8 g of the surface hydroxylated LiMnPO 4 / C material, dispersed in 20mL of deionized water, stirred evenly, to obtain a dispersion; then, weighed 0.08g of vanadium pentoxide, dissolved in 4ml of deionized water containing hydrogen peroxide, stirred to form a sol, under stirring conditions Add to the above dispersion liquid, then add 4ml deionized water to the mixed liquid and stir and mix for 1 hour; then dry at 80°C; finally mix the dried mixture with 1.8g polyvinyl alcohol, under argon protective atmosphere , baked at 600°C for 6 hours to obtain a coating of 1% V 2 o 5 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com