Corrosion-resistant and explosion-proof motor driven with assistance of wastewater

A drive motor, corrosion-resistant technology, used in engine components, machines/engines, mechanical equipment, etc., can solve the problems of poor mechanical performance, high cost, and low service life of motors, and achieve anti-corrosion ability and anti-cavitation wear performance. The effect of improving, increasing mechanical strength and load-carrying capacity, reducing the risk of bursting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

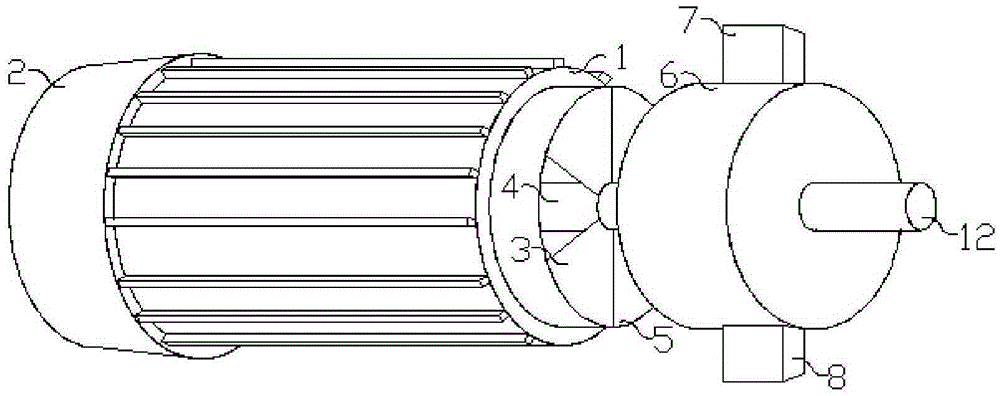

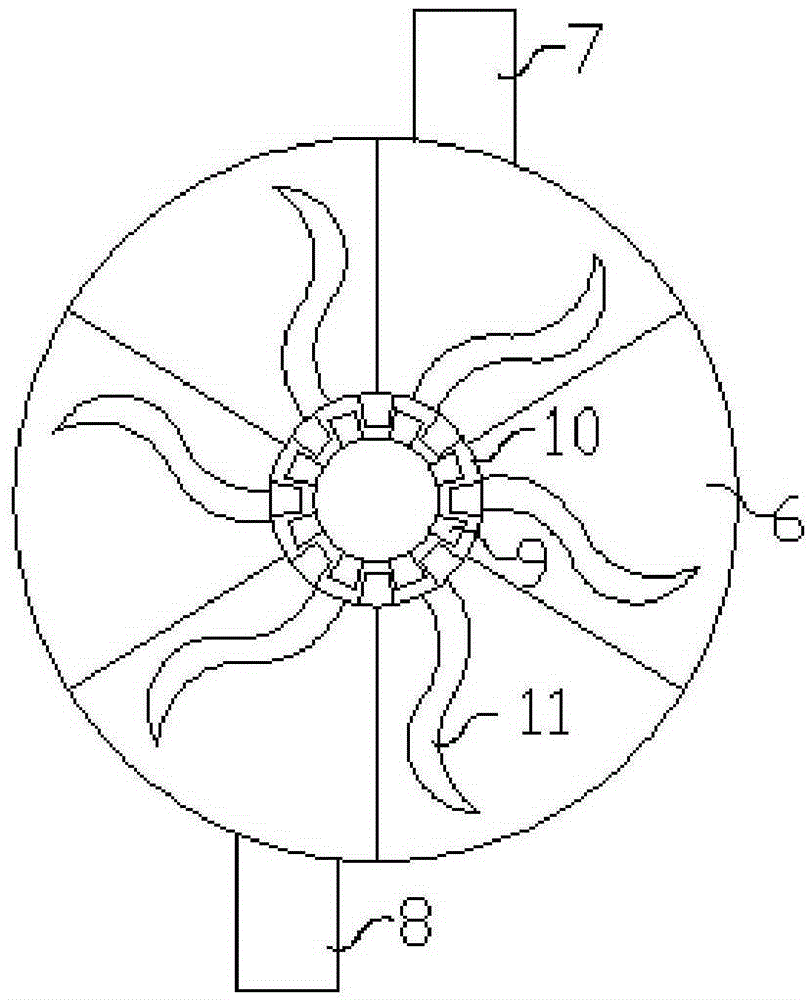

[0017] Attached below Figure 1-3 And embodiment further illustrate the present invention.

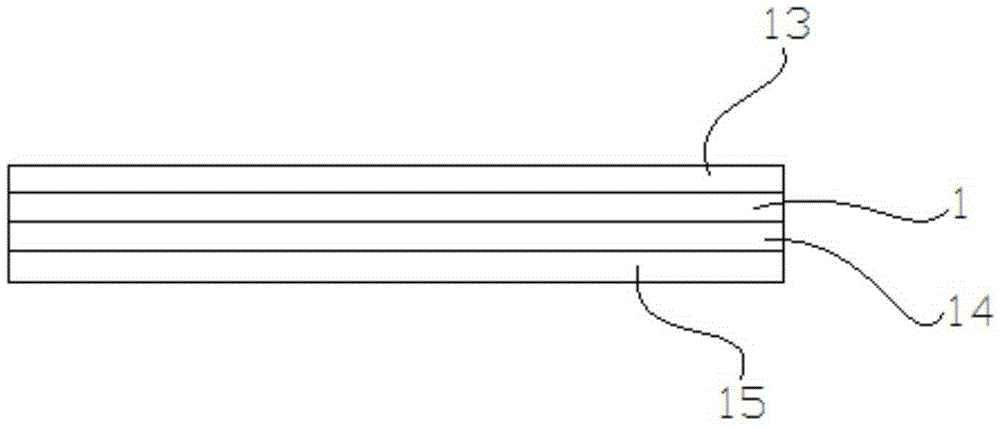

[0018] A corrosion-resistant and explosion-proof waste water assisting drive motor, including a casing 1 and a cover 2 set on one end of the casing 1, a motor unit is arranged inside the casing 1, a turntable 3 is connected to one end of the casing 1, and the inside of the turntable 3 There is a transmission shaft 4, one end of the transmission shaft 4 is connected to the motor unit, the other end of the transmission shaft 4 is connected to the waste water driver 6, the top of the waste water drive 6 is connected to the water inlet pipe 7, and the bottom of the water inlet pipe 7 is connected to the waste water pipe, the waste water driver The bottom of 6 is connected with an outlet pipe 8, and the interior of the waste water driver 6 is provided with a transmission wheel 10, the waste water driver 6 is connected to the transmission shaft 4 through the transmission wheel 10, and the cy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com