Antibacterial composite material, preparation method and application thereof

A composite material and carbon material technology, applied in the field of antibacterial composite materials, can solve the problems of common urinary catheters that do not have bactericidal effect, easily cause urinary system infection, environmental heavy metal pollution, etc., to prevent infection problems, reduce medical costs, Easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

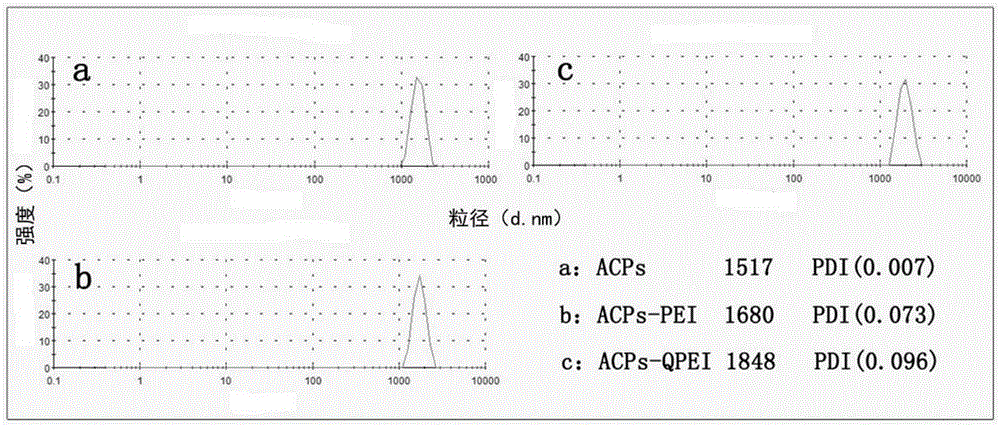

[0041] Example 1 Preparation of quaternized polyethyleneimine amphiphilic bio-carbon material particles

[0042] (1) Shake 10g of yeast to disperse, take the gray-white bacterial suspension in the upper layer and centrifuge, discard the waste liquid, then add 20ml of acetone, shake for 5-20min, centrifuge, discard the acetone, repeat the same method 3-5 times , disperse the substrate with 2% glutaraldehyde aqueous solution, pour it into a high-temperature and high-pressure reactor, and react at 150-200°C for 8-10h. After the reaction, cool to room temperature, pour off the upper layer solution, and use the lower layer precipitation Repeated ultrasonic washing with distilled water, and finally drying in an oven to obtain amphiphilic bio-carbon material particles.

[0043] (2) Weigh 200 mg of amphiphilic bio-carbon material particles and ultrasonically disperse them in 20 ml of PB buffer solution (PH5.5), and add an appropriate amount of 1-(3-dimethylaminopropyl)-3-ethylcarbodie...

Embodiment 2

[0045] Embodiment 2 prepares quaternized polyethyleneimine carbon slag particle / silicone rubber mixture

[0046] Add 50 mg of quaternized polyethyleneimine carbon slag particles into 5 g of silicone rubber liquid at a mass fraction of 1:100, and mix well;

[0047] 1. Preparation of antibacterial silicone rubber catheter

[0048] The above mixture is made into a novel antibacterial urinary catheter according to the preparation process of a conventional urinary catheter.

[0049] 2. Tensile properties, tear properties, elastic modulus, elongation at break and Shore A hardness test results

[0050]

[0051] 3. Antibacterial effect test results

[0052] Escherichia coli (E.coli) isolates were selected as Gram-negative bacteria for testing the antibacterial activity of the membrane and Staphylococcus aureus (S.aureus) isolates were selected as Gram-positive bacteria for testing the antibacterial activity of the membrane, antibacterial particles Test results such as Figure 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com