Center hole out-of-roundness detection method of shaft parts

A technology of shaft parts and detection method, applied in the field of shaft parts, can solve problems such as inability to obtain quantitative and accurate measurement, and achieve the effect of improving results, eliminating human factors and simple measurement tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

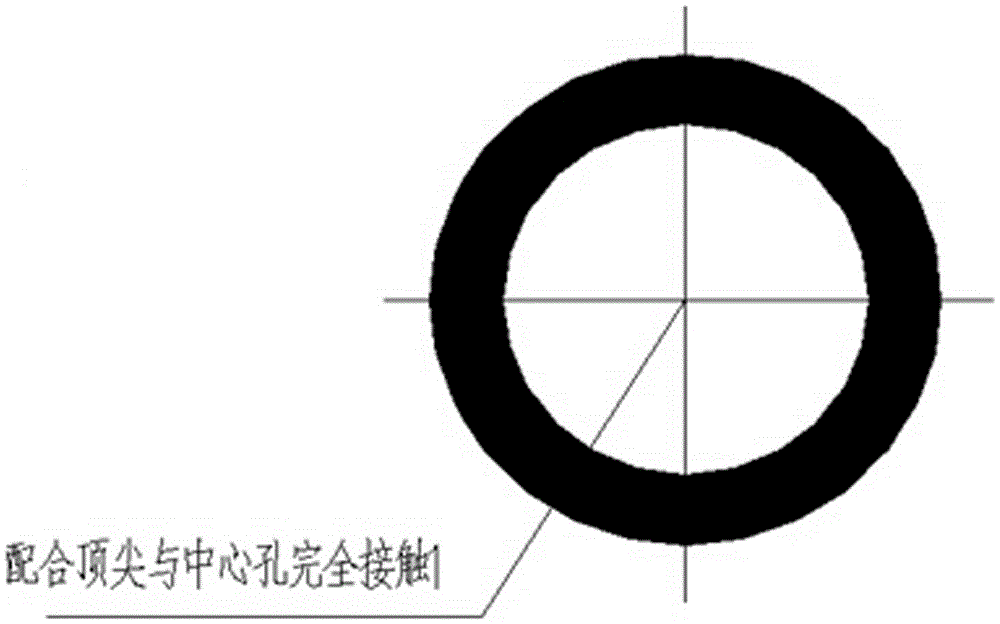

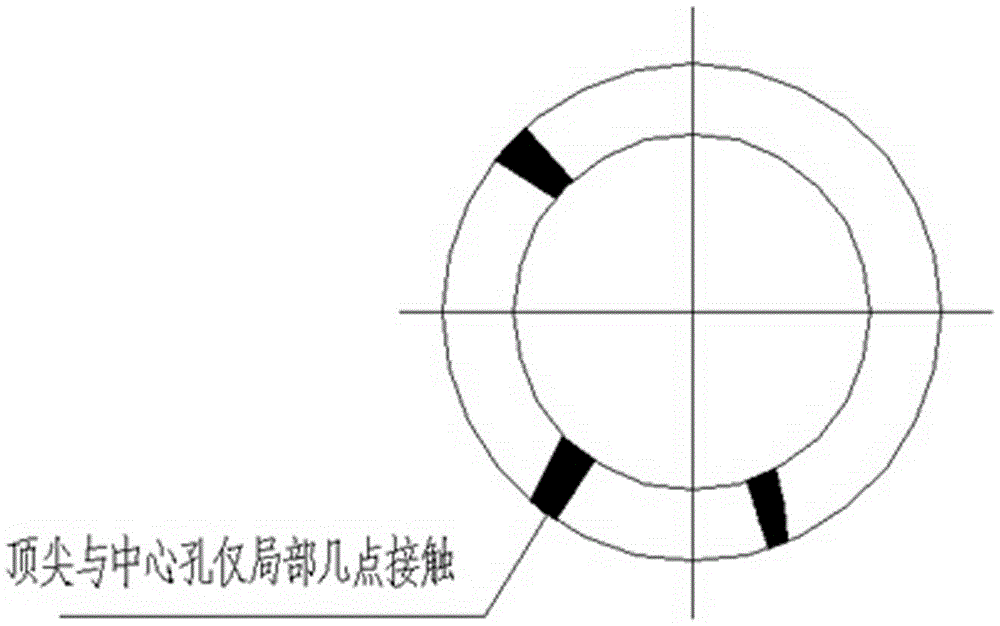

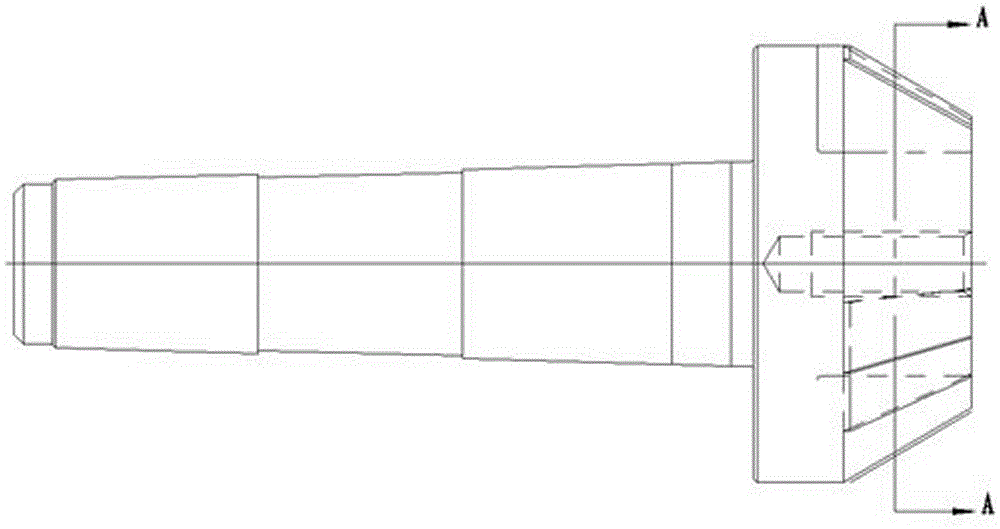

[0034] First, a top spare part of a machine tool that fits with the center hole of the workpiece is remade through tool grinding or wire cutting, and it is remade into a three-point top for testing (see Figure 4 and Figure 5 ), the top retains only three contact parts, the width is 2~3mm, and the distribution is about 120 degrees; after removing the full-shaped headstock top of the normal grinding workpiece, install the top on the machine tool for grinding the workpiece, such as Image 6 , to form the three-point center point 1 of the head frame, and then hoist the workpiece 2 with the out-of-round center hole to be inspected to the machine tool for clamping. The dead center 3 of the frame cooperates, and the dead center 3 of the tailstock plays the role of support and positioning. Use a marker pen to mark on the three-point center 1 of the head frame and the workpiece 2 respectively (such as Figure 7 The black dot in ●), then jog the button of the machine tool, and the sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com