Small plate table type chamfering machine

A chamfering machine and desktop technology, applied in the details of milling machine equipment, metal processing equipment, milling machine equipment, etc., can solve the problems of small workpieces that are not easy to fix, unsafe operation, and small boards that are easy to rust and corrode.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

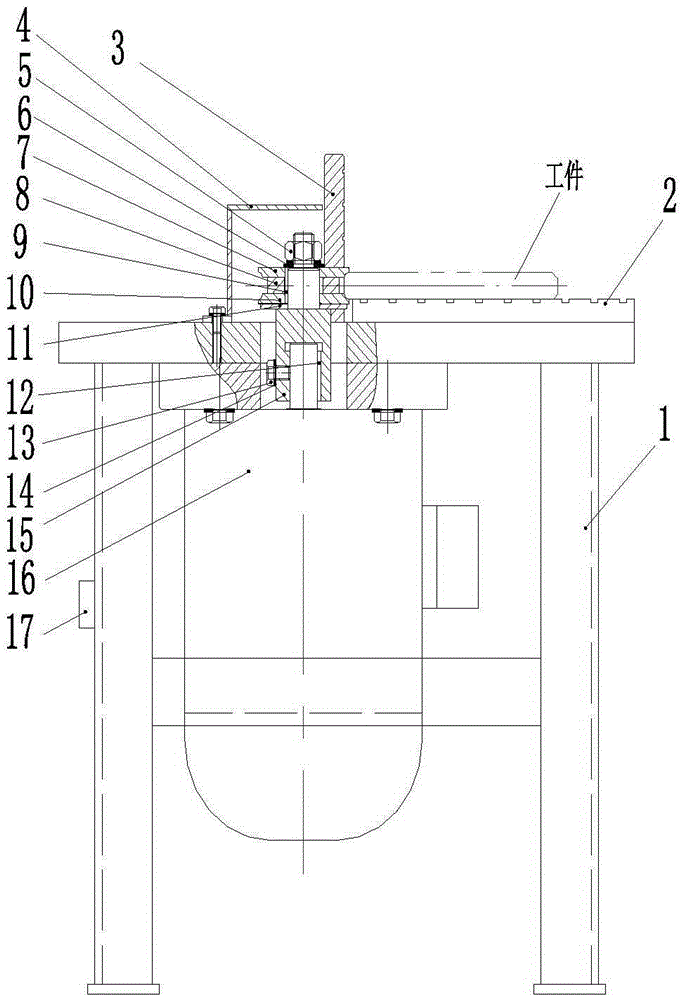

[0019] Now in conjunction with accompanying drawing, the present invention will be further described, as figure 1 As shown, including frame, motor, milling cutter, cutter cover, replaceable pad, pallet and backing plate. The motor is placed under the table of the rack; the output shaft of the motor is connected to the main shaft, and the other end of the main shaft passes through the table of the rack vertically to connect with the milling cutter;

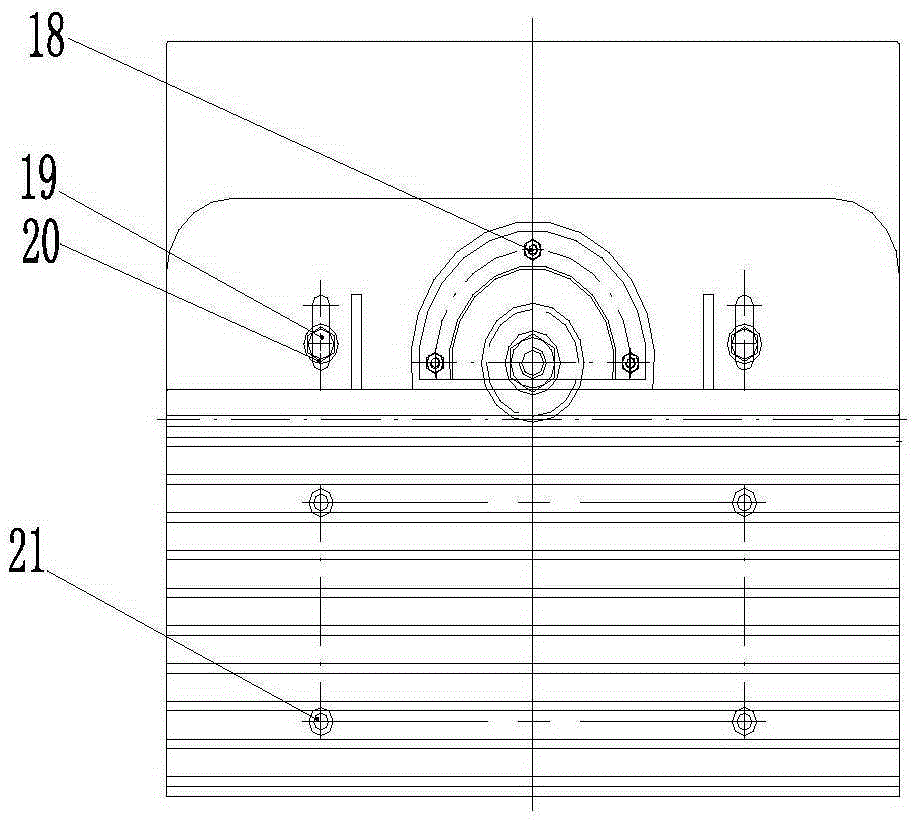

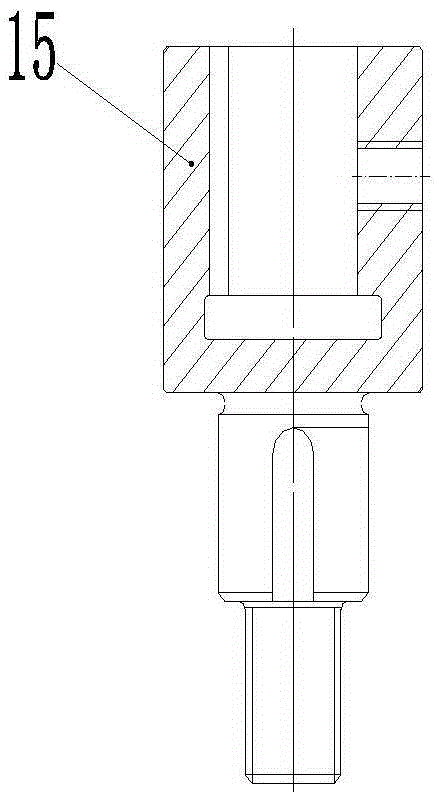

[0020] Install the motor at the lower end of the rack table, dig a hole on the rack table to let the main shaft pass through, and the main shaft sleeve and key make the main shaft tightly fit on the output shaft end of the motor (such as image 3 shown); the supporting plate is fixed on the frame table by fastening the countersunk bolts of the supporting plate, and the backing plate is fixed on the frame table by the backing plate adjustment bolts and washers, and the front and rear positions of the backing plate are adjustable (su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com