Low-electric conductivity liquid-state tritium proliferation agent for fusion and preparation method thereof

A tritium breeder, low-conductivity technology, applied in the field of low-conductivity liquid tritium breeder for fusion and its preparation, can solve the problems of low electrical conductivity, MHD effect, etc., achieve low electrical conductivity, increase outlet temperature, and simplify packaging. The effect of layer structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

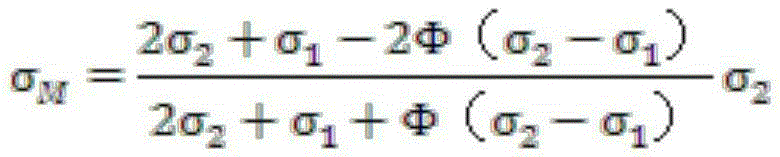

[0028] The invention discloses a low-conductivity liquid tritium breeder for fusion, the tritium breeder is a mixture of liquid matrix and dispersed particles, and the conductivity is 1-10 6 Between s / m, it contains the following components: liquid proliferation agent matrix, dispersed particles;

[0029] The matrix of the liquid proliferator is metallic lithium (Li), or lithium tin (LiSn), or liquid lead-lithium eutectic (LiPb), or other liquid alloys containing lithium, or liquid molten salt substances;

[0030] The dispersed particles are in the form of nanoparticles or microparticles with a particle size ranging from 1nm to 1mm, and the material is silicon carbide (SiC) or aluminum oxide (Al 2 o 3 ), or beryllium oxide (BeO), or silicon dioxide (SiO 2 ), or erbium oxide (Er 2 o 3 ), or lithium silicate (Li 2 SiO 3 ), or lithium orthosilicate (Li 4 SiO 4 ), or lithium titanate (Li 2 TiO 3 ), or lithium oxide (Li 2 O), or lithium metaaluminate (LiAlO 2 ), or lith...

Embodiment 3

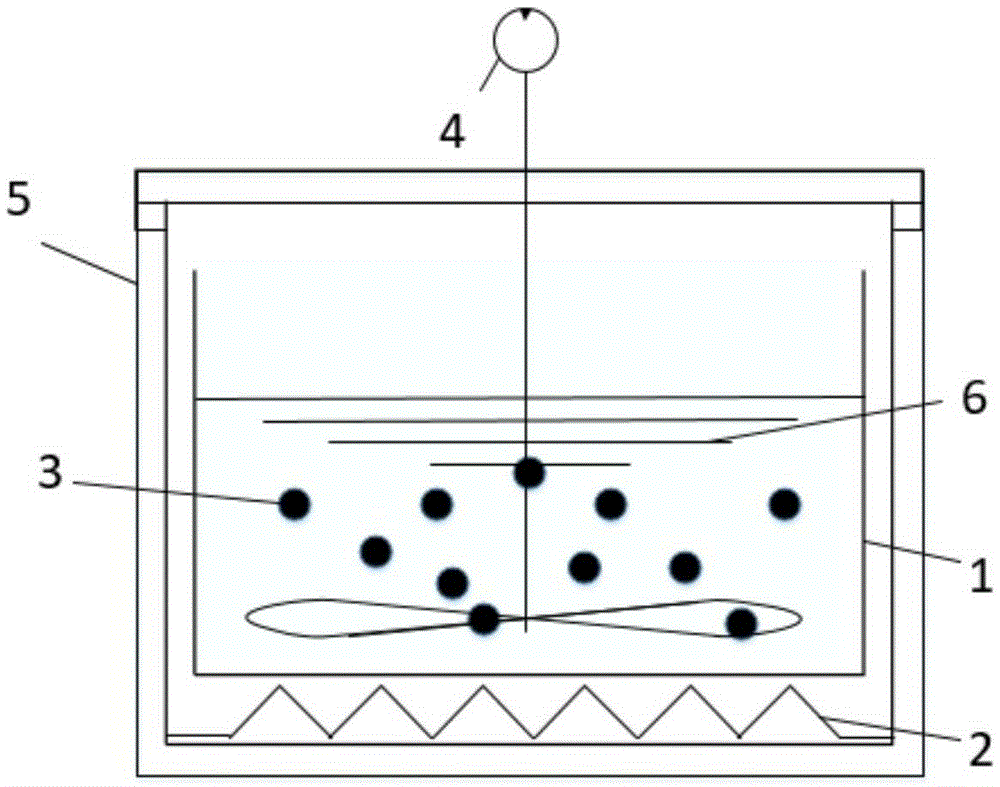

[0037] Such as figure 1 Shown is the schematic diagram of the preparation equipment of the present invention, and the following is the implementation method formed in the process of preparing the low-conductivity liquid tritium multiplier of the present invention:

[0038] Step 1: Select insulating nanoparticles or microspheres;

[0039] Step 2: Carry out high-temperature calcination and purging treatment with inert gas at the same time;

[0040] Step 3: modifying the particle surface;

[0041]Step 4: By volume, the calcined insulating nanoparticles or microsphere particles 3 are mixed with the liquid metal 6 matrix;

[0042] Step 5: Melt the liquid metal 6 in the atmosphere-protected or vacuum high-temperature furnace 5, and heat the original 2 through the high-temperature heating furnace to control the temperature range at 200°C-1000°C;

[0043] Step 6: Stir the liquid metal or molten salt added with insulating particles for 0.5-12 hours by mechanical stirring device 4 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com