Open trench tunnel main structure tall side wall unilateral vertical mold and construction process thereof

A main structure, open-cut tunnel technology, applied in infrastructure engineering, underwater structures, artificial islands, etc., can solve the problems of difficult to guarantee construction quality, large demolition workload, long erection period, etc., to improve construction efficiency and The effect of engineering progress, high stability of the support, and improvement of construction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

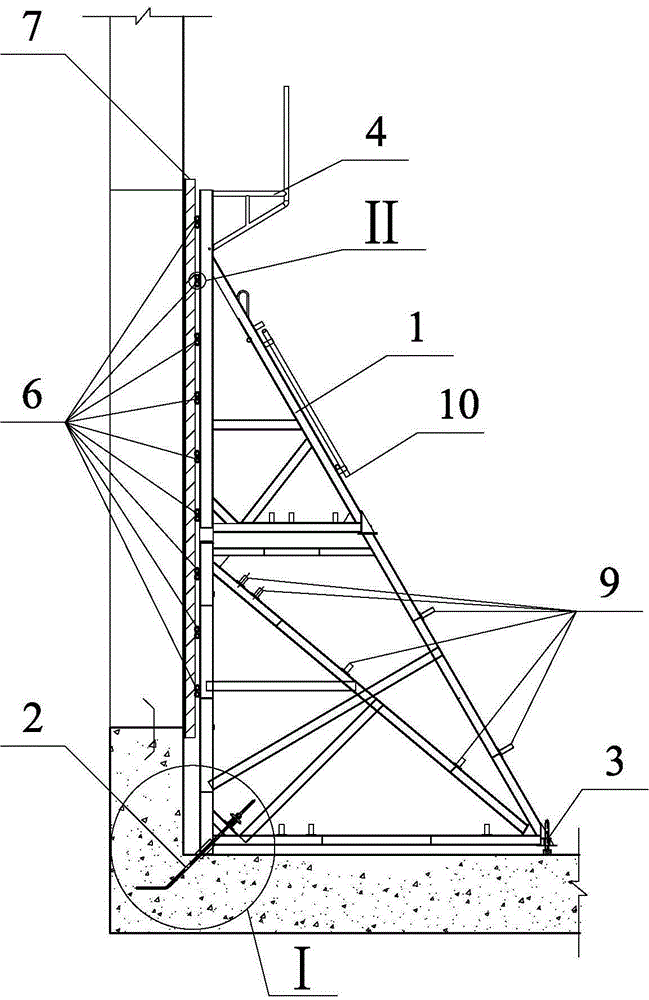

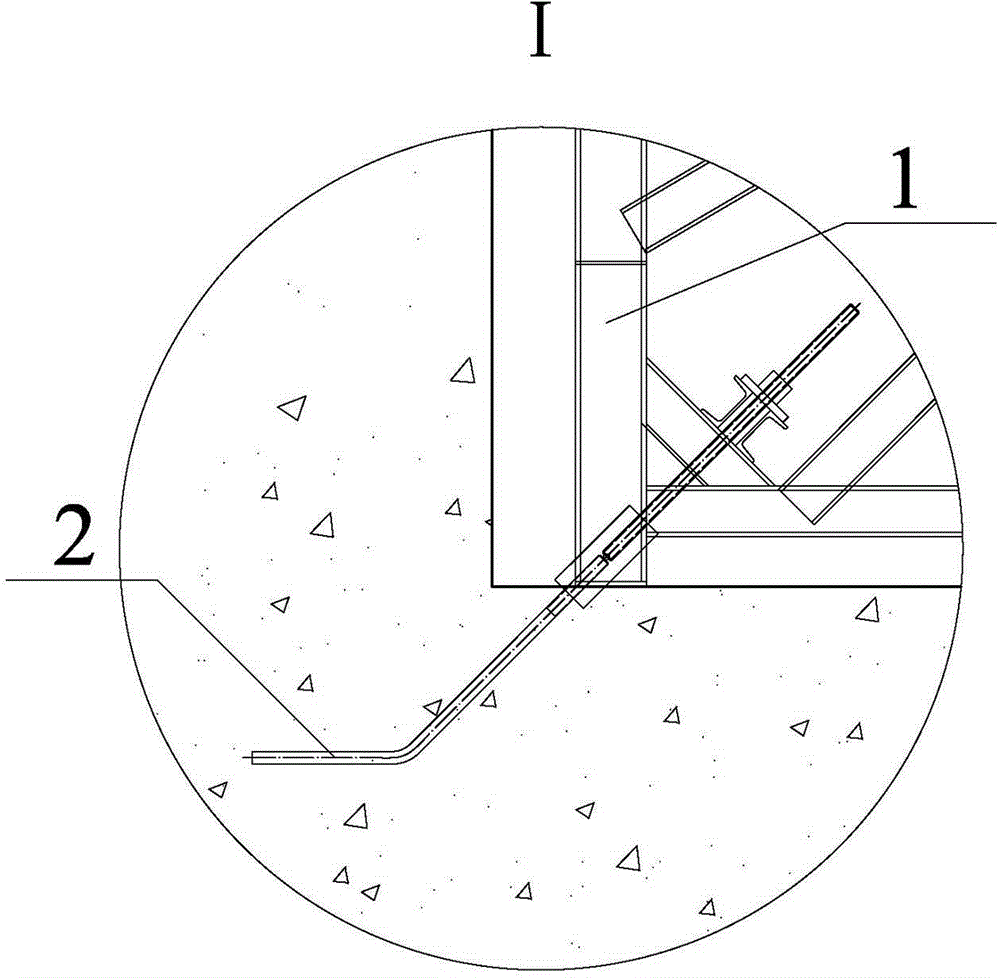

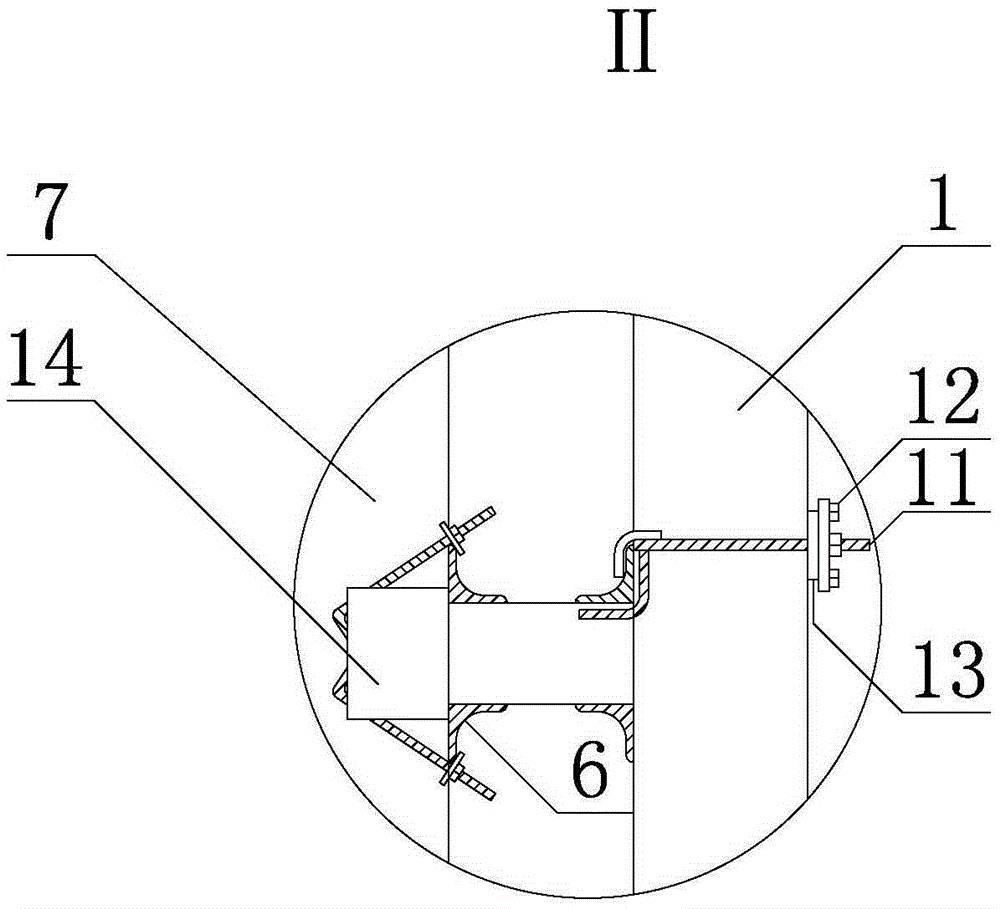

[0015] The main structure of the open-cut tunnel is one-sided vertical formwork with tall side walls, such as figure 1 As shown, the shaped steel triangular truss 1 including a right-angled triangle, the bottom side of the shaped steel triangular truss 1 is obliquely provided with embedded anchor bolts 2, and several pressure beam channel steels 9 are arranged on the shaped steel triangular truss 1, and the right-angled sides of the shaped steel triangular truss 1 The formwork 7 is installed on the outside of the long side, and several connection devices are arranged between the steel triangular truss 1 and the formwork 7. One end of the connection device is located inside the formwork 7 on one side of the steel triangle truss 1, and the hypotenuse of the steel triangle truss 1 is installed along the length direction. The steel pipes 10 are connected horizontally, and the operating platform 4 is installed on the top of the shaped steel triangular truss 1 . This structure adopt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com