Method for preparing oat beta-glucan through ball milling

A glucan and ball milling technology, which is applied in the field of oat β-glucan preparation by ball milling, can solve the problems of low utilization rate of protease, low reaction efficiency, large enzyme consumption, etc., and achieve shortened enzymatic hydrolysis time, high purity, good value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

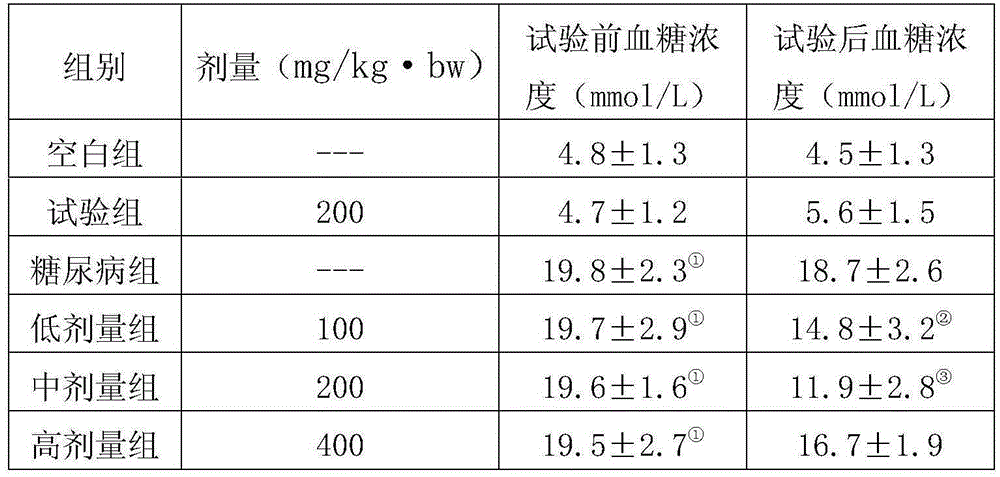

Examples

Embodiment 1

[0024] A method for preparing oat β-glucan by ball milling includes the following steps:

[0025] (1) Pretreatment: the oats are cleaned and screened first, then crushed, and passed through a 40-mesh sieve to obtain oat flour;

[0026] (2) Degreasing treatment: soak the oat flour obtained in step (1) with 75% ethanol at 70°C for 1.5 hours, cool, and pour the upper liquid to obtain precipitated oat flour;

[0027] (3) Microwave drying: microwave drying of the precipitated oat flour obtained in step (2): microwave power 50kW, microwave time 12min;

[0028] (4) Alkaline water extraction: first soak the oatmeal obtained in step (3) with warm water at 35°C for 5 minutes, where the material-to-liquid ratio is 1:12, and then use a ball mill with a rotating speed of 120 revolutions / min. Ball mill for 15 minutes, then adjust the pH value of the mixture after ball milling to 10.0 with sodium carbonate solution, and finally continue to ball mill with a ball mill at a speed of 180 revolutions / min...

Embodiment 2

[0040] A method for preparing oat β-glucan by ball milling includes the following steps:

[0041] (1) Pretreatment: the oats are cleaned and screened first, then crushed, and passed through a 40-mesh sieve to obtain oat flour;

[0042] (2) Degreasing treatment: soak the oat flour obtained in step (1) with 80% ethanol at 80°C for 2 hours, cool, and pour the upper liquid to obtain precipitated oat flour;

[0043] (3) Microwave drying: microwave drying of the precipitated oat flour obtained in step (2): microwave power 60kW, microwave time 15min;

[0044] (4) Alkaline water extraction: first soak the oatmeal obtained in step (3) with warm water at 40°C for 7 minutes, where the material-to-liquid ratio is 1:15, and then use a ball mill with a speed of 150 revolutions / min. Ball mill for 20 minutes, then adjust the pH value of the mixture after ball milling to 11.0 with sodium carbonate solution, and finally continue to ball mill with a ball mill at a speed of 200 revolutions / min, ball mill...

Embodiment 3

[0056] A method for preparing oat β-glucan by ball milling includes the following steps:

[0057] (1) Pretreatment: the oats are cleaned and screened first, then crushed, and passed through a 40-mesh sieve to obtain oat flour;

[0058] (2) Degreasing treatment: soak the oat flour obtained in step (1) with 70% ethanol at 60°C for 1 hour, cool, and pour the upper liquid to obtain precipitated oat flour;

[0059] (3) Microwave drying: microwave drying of the precipitated oat flour obtained in step (2): microwave power 40kW, microwave time 10min;

[0060] (4) Alkaline water extraction: first soak the oatmeal obtained in step (3) in warm water at 30°C for 3 minutes, where the material-to-liquid ratio is 1:10, and then use a ball mill with a speed of 100 revolutions / min. Ball mill for 10 minutes, then adjust the pH value of the mixture after ball milling with sodium carbonate solution to 9.0, and finally continue to ball mill with a ball mill with a speed of 150 revolutions / min, ball mill f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com