Hardly-degradable organic wastewater comprehensive treatment and zero discharge treatment method and system thereof

A technology for comprehensive treatment of organic wastewater, applied in multi-stage water treatment, water/sewage treatment, chemical instruments and methods, etc., can solve problems such as failure to meet national discharge standards, outdated process technology, difficult to effectively remove, etc., to improve freshwater The effects of productivity, pollution reduction, and chemical consumption are small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

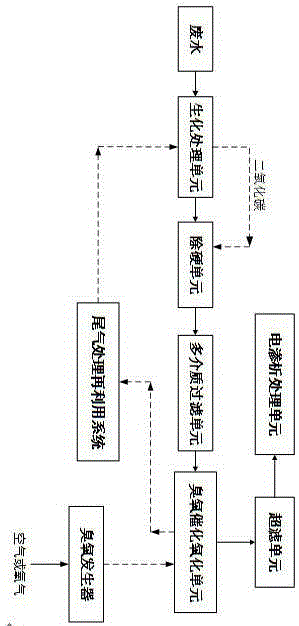

Image

Examples

Embodiment 1

[0034] Take the wastewater treatment of a coal chemical plant as an example.

[0035] Coal chemical industry wastewater contains high concentrations of refractory organic pollutants and ammonia nitrogen. The main organic components are volatile phenols, benzenes, nitrogen-containing heterocyclic compounds, biphenyls, petroleum, etc. COD is 4000mg / L, volatile phenol is 800mg / L, ammonia nitrogen is 100mg / L, and conductivity is 4000μs / cm.

[0036] The pretreated coal chemical wastewater enters the biochemical treatment system, usually using a pre-denitrification biological denitrification process, such as anoxic-aerobic (A / O) process. The denitrifying bacteria in the anoxic reactor use the organic pollutants in the coal chemical industry wastewater as the carbon source, and the nitrosonitrogen or nitronitrogen in the reflux supernatant as the electron acceptor to carry out respiration and life activities and reduce them into nitrogen (N 2 ) escape, to achieve denitrification an...

Embodiment 2

[0040] Take the wastewater treatment of a coal chemical plant as an example.

[0041] Coal chemical industry wastewater contains high concentrations of refractory organic pollutants and ammonia nitrogen. The main organic components are volatile phenols, benzenes, nitrogen-containing heterocyclic compounds, biphenyls, petroleum, etc. COD is 5000mg / L, volatile phenol is 1000mg / L, ammonia nitrogen is 150mg / L, and conductivity is 5000μs / cm.

[0042] The pretreated coal chemical wastewater enters the biochemical treatment system, usually using a pre-denitrification biological denitrification process, such as anoxic-aerobic (A / O) process. The denitrifying bacteria in the anoxic reactor use the organic pollutants in the coal chemical industry wastewater as the carbon source, and the nitrosonitrogen or nitronitrogen in the reflux supernatant as the electron acceptor to carry out respiration and life activities and reduce them into nitrogen (N 2 ) escape, to achieve denitrification a...

Embodiment 3

[0046] Take the wastewater treatment of a coal chemical plant as an example.

[0047] Coal chemical industry wastewater contains high concentrations of refractory organic pollutants and ammonia nitrogen. The main organic components are volatile phenols, benzenes, nitrogen-containing heterocyclic compounds, biphenyls, petroleum, etc. COD is 6000mg / L, volatile phenol is 1500mg / L, ammonia nitrogen is 200mg / L, and conductivity is 5000μs / cm.

[0048] The pretreated coal chemical wastewater enters the biochemical treatment system, usually using a pre-denitrification biological denitrification process, such as anoxic-aerobic (A / O) process. The denitrifying bacteria in the anoxic reactor use the organic pollutants in the coal chemical industry wastewater as the carbon source, and the nitrosonitrogen or nitronitrogen in the reflux supernatant as the electron acceptor to carry out respiration and life activities and reduce them into nitrogen (N 2 ) escape, to achieve denitrification a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com