Preparation method of high-adsorbability cellulose diacetate composite electrostatic spinning nanofiber ordered porous film

A technology of cellulose diacetate and porous film, applied in the direction of artificial filaments made of cellulose derivatives, electrospinning, separation methods, etc., to achieve the effect of feasible operation, small fiber diameter, and good dry state adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

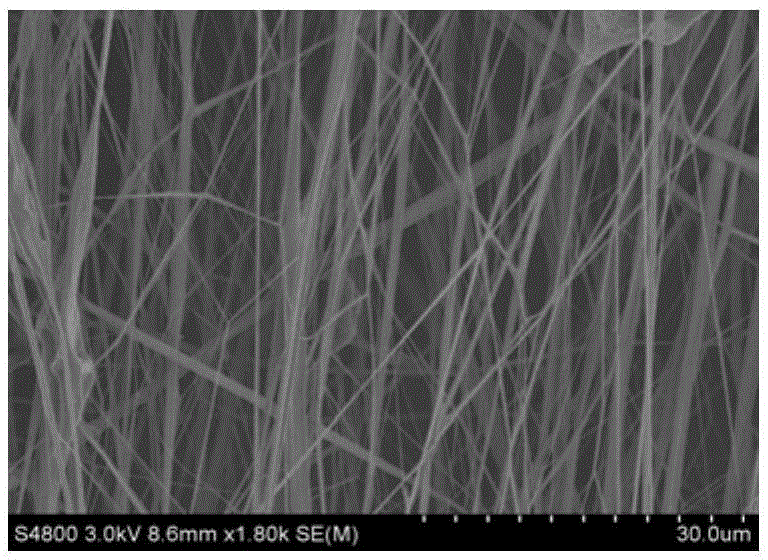

[0044] Put 0.375g of cellulose diacetate and 0.125g of polycaprolactone (PCL) into a mixed solvent of 6.67mL of acetone and 3.33mL of chloroform, and stir until completely dissolved to obtain a solution with a volume concentration of 5%. The prepared solution was sucked into the syringe, and the ordered porous film of cellulose diacetate nanofibers was prepared by using an electrospinning machine. The receiving distance between the needle and the receiving roller was 18 cm. The ordered porous film of cellulose diacetate nanofiber prepared in this example is shown in figure 1 , fiber diameter see Figure 17 , aperture see Figure 18 , for order, see Figure 19 , and has a fiber diameter of 0.45±0.17 μm, a pore diameter of 5.43±1.18 μm, and an order degree of 79.43±7.40°. Its scanning electron micrographs after adsorbing particles 11d under dry conditions are as follows: Figure 4 As shown, the particle morphology after adsorbing particles under dry conditions is as follow...

Embodiment 2

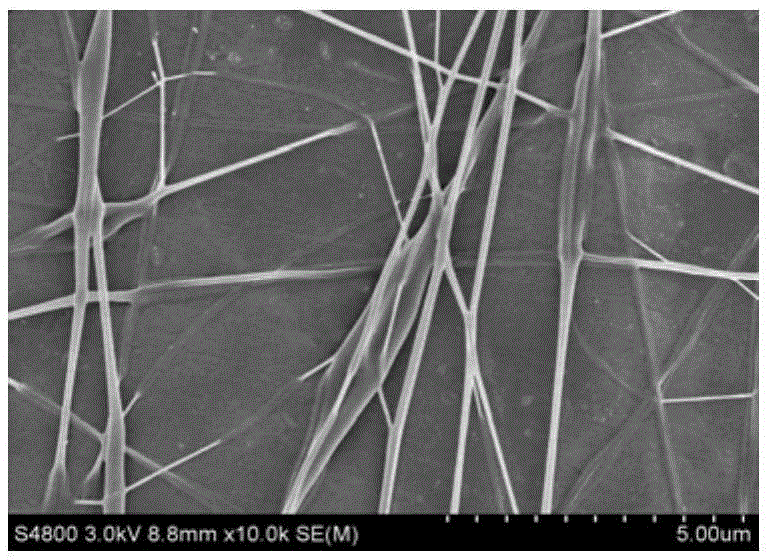

[0046] Put 0.375g of cellulose diacetate and 0.125g of polylactic-co-glycolic acid (PLGA) into a mixed solvent of 6.67mL of acetone and 3.33mL of chloroform, and stir until completely dissolved to obtain a volume concentration of 5%. solution. The prepared solution was sucked into the syringe, and the ordered porous film of cellulose diacetate nanofibers was prepared by using an electrospinning machine. The receiving distance between the needle and the receiving roller was 18 cm. The ordered porous film of cellulose diacetate nanofiber prepared in this example is shown in figure 2 , fiber diameter see Figure 17 , aperture see Figure 18 , for order, see Figure 19 , with a fiber diameter of 0.13±0.05 μm, a pore diameter of 2.48±2.10 μm, and an order degree of 80.89±2.66°. Its scanning electron micrograph after adsorbing particles 11d under dry conditions is as follows: Image 6 As shown, the particle morphology after adsorbing particles under dry conditions is as follo...

Embodiment 3

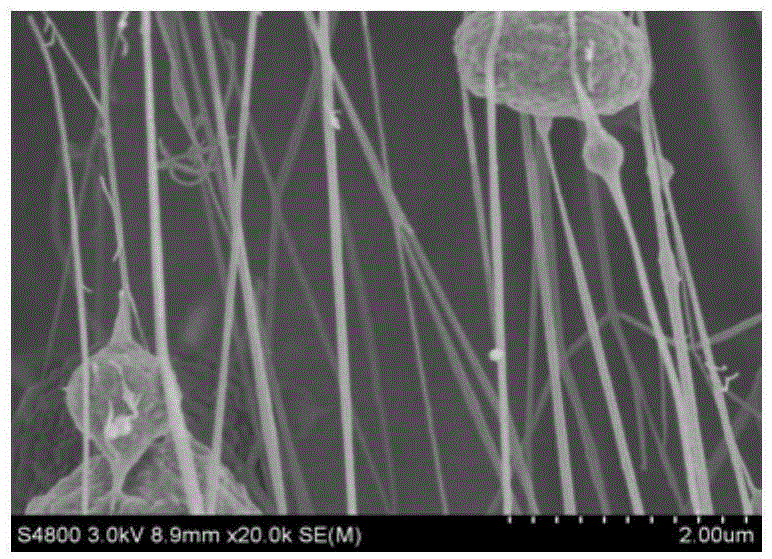

[0048]Put 0.9 g of cellulose diacetate and 0.3 g of polyvinylpyrrolidone (PVP) into a mixed solvent of 6.67 mL of dimethylformamide and 3.33 mL of methanol, and stir until completely dissolved to obtain a solution with a volume concentration of 12%. The prepared solution was sucked into the syringe, and the ordered porous film of cellulose diacetate nanofibers was prepared by using an electrospinning machine. The receiving distance between the needle and the receiving roller was 18 cm. The ordered porous film of cellulose diacetate nanofiber prepared in this example is shown in image 3 , fiber diameter see Figure 17 , aperture see Figure 18 , for order, see Figure 19 , with a fiber diameter of 0.12±0.04 μm, a pore diameter of 3.48±2.50 μm, and an order degree of 90.24±3.12°. Its scanning electron micrographs after adsorbing particles 11d under dry conditions are as follows: Figure 8 As shown, the particle morphology after adsorbing particles under dry conditions is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com