Paclitaxel loaded catenulate nano fiber and preparation method thereof

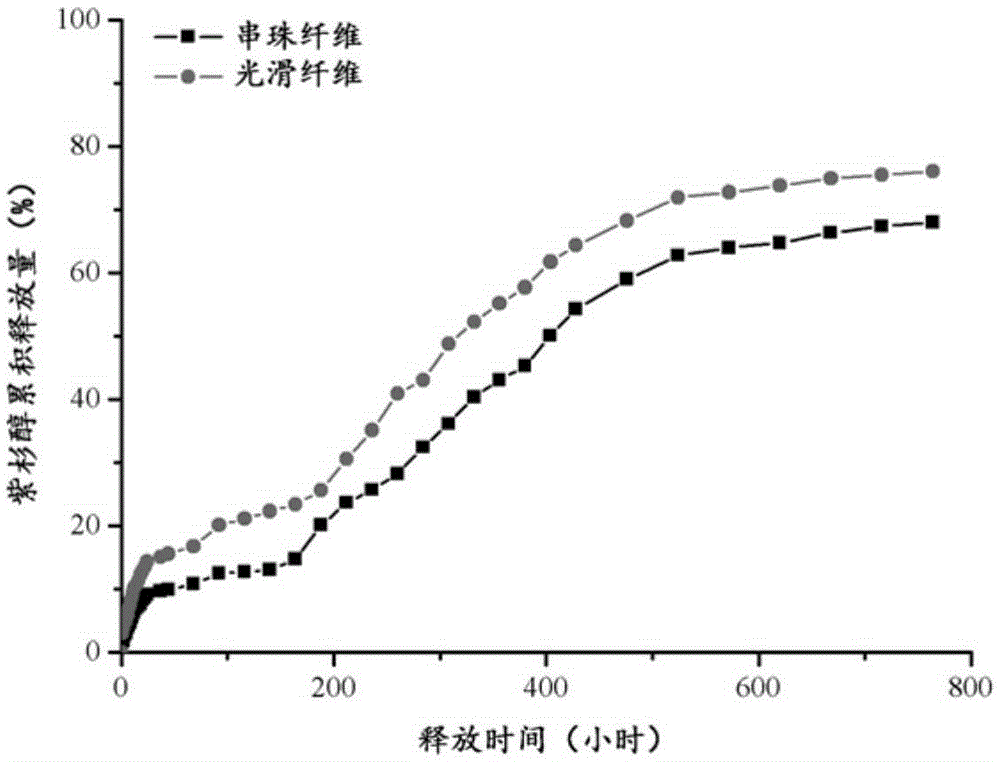

A nanofiber and paclitaxel technology, applied in fiber treatment, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of uncontrollable drug release time and rate, inability to change the appropriate rate, large diameter of microsphere drug, etc., to achieve relief Effects of drug burst release, improved drug efficiency, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) Prepare 14wt% polycaprolactone (PCL, molecular weight is 8×10 4 Da) solution, the solvent used is obtained by mixing the first solvent dichloromethane and the second solvent N,N-dimethylformamide with a mass ratio of 10:4;

[0034] 2) prepare 6wt% polyethylene glycol (PEG, molecular weight is 6 * 10 3 Da) solution, the solvent used is obtained by mixing the first solvent dichloromethane and the second solvent N,N-dimethylformamide with a mass ratio of 10:4;

[0035] 3) Mix the polycaprolactone solution in step 1) with the polyethylene glycol solution in step 2) according to the mass ratio of 1:1, then add paclitaxel to it to make the final concentration 5wt%, stir evenly, Obtain paclitaxel solution;

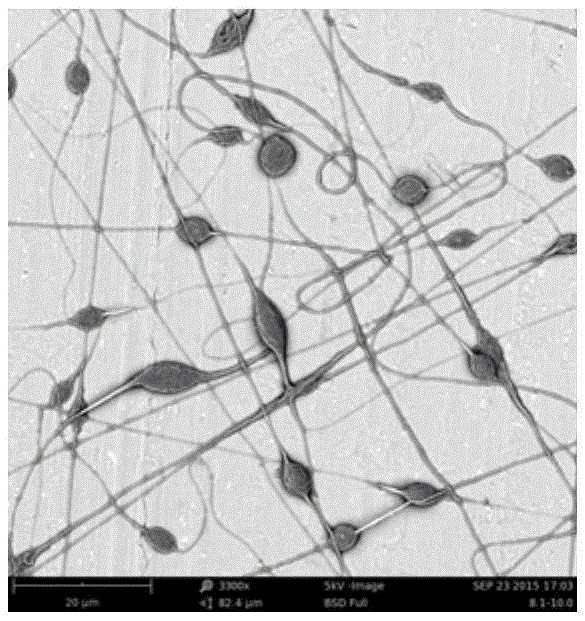

[0036] 4) Add the paclitaxel solution in step 3) into a 2.5mL syringe, and perform electrospinning at a spinning voltage of 6kV and a spinning flow rate of 0.5mL / h (the schematic diagram of the electrospinning device is shown in figure 1 shown, the same below), the h...

Embodiment 2

[0039] 1) prepare 14wt% polycaprolactone (molecular weight is 8 * 10 4 Da) solution, the solvent used is obtained by mixing the first solvent dichloromethane and the second solvent N,N-dimethylformamide with a mass ratio of 10:4;

[0040] 2) prepare 6wt% polyethylene glycol (molecular weight is 6 * 10 3 Da) solution, the solvent used is obtained by mixing the first solvent dichloromethane and the second solvent N,N-dimethylformamide with a mass ratio of 10:4;

[0041] 3) Mix the polycaprolactone solution in step 1) with the polyethylene glycol solution in step 2) according to the mass ratio of 1:1, then add paclitaxel to it to make the final concentration 3wt%, stir evenly, Obtain paclitaxel solution;

[0042] 4) Add the paclitaxel solution in step 3) into a 2.5mL syringe, and perform electrospinning at a spinning voltage of 6kV and a spinning flow rate of 0.9mL / h. The needle of the syringe is the level of the spinneret and the flat receiver The distance is 15cm, the flat r...

Embodiment 3

[0045] 1) prepare 14wt% polycaprolactone (molecular weight is 8 * 10 4 Da) solution, the solvent used is obtained by mixing the first solvent dichloromethane and the second solvent N,N-dimethylformamide with a mass ratio of 10:4;

[0046] 2) prepare 6wt% polyethylene glycol (molecular weight is 1 * 10 4 Da) solution, the solvent used is obtained by mixing the first solvent dichloromethane and the second solvent N,N-dimethylformamide with a mass ratio of 10:4;

[0047] 3) Mix the polycaprolactone solution in step 1) with the polyethylene glycol solution in step 2) according to the mass ratio of 1:1, then add paclitaxel to it to make the final concentration 6wt%, stir evenly, Obtain paclitaxel solution;

[0048] 4) Add the paclitaxel solution in step 3) into a 2.5mL syringe, and perform electrospinning at a spinning voltage of 6kV and a spinning flow rate of 0.6mL / h. The needle of the syringe is the level of the spinneret and the flat receiver The distance is 15cm, and the fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com