Method for manufacturing penetration layer for improving high-temperature-oxidation resistance of K444 alloy

An anti-high temperature oxidation and alloy technology, which is applied in the field of heat treatment, can solve the problems of reduced oxidation resistance, low aluminum concentration of the permeated layer, and insufficient stability of the vapor phase aluminized process, and achieves improved high temperature protection performance, smooth surface, and improved high temperature oxidation. The effect of protective performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

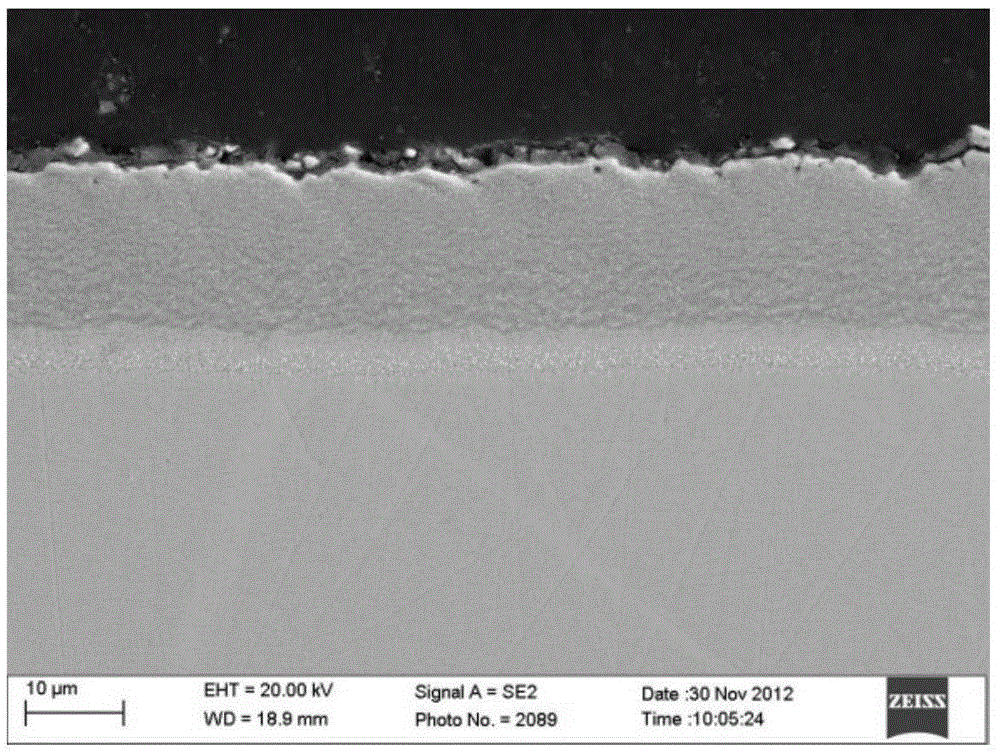

[0023] In the specific implementation process, the present invention improves the infiltration layer preparation method of K444 alloy high-temperature oxidation resistance performance, and the specific steps are as follows:

[0024] (1) Configuration of aluminized silicon slurry: use polyvinyl alcohol aqueous solution as binder, Si powder, Ni-Al alloy (nickel-aluminum weight ratio is 1:1) powder, ammonium chloride, ammonium hydrogen fluoride, bond Mix the agent and ethanol to make a slurry, and spray it on the surface of K444 alloy parts.

[0025] (2) The formulation of aluminized silicon parameters: use a well-type heat treatment furnace protected by argon gas, put the sample into the fixture under the protection of argon gas, and explore through experiments to select the temperature of aluminized silicon, and after a certain period of heat preservation An aluminum-silicon coating is obtained.

[0026] (3) Diffusion temperature and diffusion time: In order to reduce the brit...

Embodiment

[0029] In this embodiment, the preparation method of the infiltrated layer for improving the high temperature oxidation resistance of the K444 alloy blade, the specific steps are as follows:

[0030] (1) Infiltration agent 100g (silicon powder, nickel-aluminum alloy powder, ammonium chloride, nickel-aluminum alloy powder is weighed by outer layer aluminum content 23wt%, silicon powder is weighed by outer layer silicon content 6wt%, ammonium chloride accounts for 5% of silicon powder, nickel-aluminum alloy powder weight), ammonium bifluoride 0.2g, binding agent 10ml (concentration is the polyvinyl alcohol aqueous solution of 10wt%) and ethanol 50ml after weighing in the ratio of packing into ball-milling tank and carrying out ball-milling, manufacture into slurry. In the infiltration tank, the slurry is sprayed on the surface of the K444 alloy blade with a spray gun, and each piece is sprayed 3 to 4 times.

[0031] (2) Hoist the infiltrated tank into a well-heated well furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com