Environmental protection plastic additive and preparation method thereof

A technology of environmentally friendly plastics and additives, applied in the chemical industry, can solve the problems of reduced service life of landfills, poor air quality of incinerators, abortion of pregnant women, etc., and achieves the effects of good biodegradability, strong practicability, and low concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

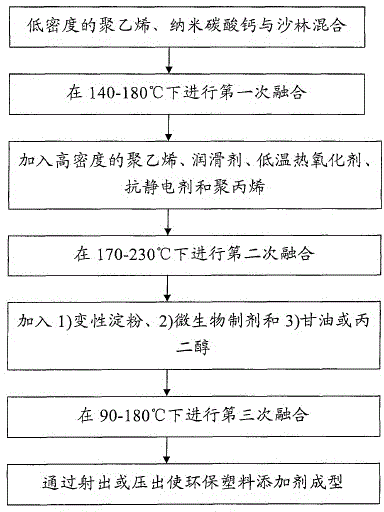

Image

Examples

Embodiment 1

[0025] First, mix low-density polyethylene, nano-calcium carbonate with a particle size of 6000-9000 mesh, and sarin resin, and then perform the first fusion at 150° C. for 8 minutes. Then add high-density polyethylene, lubricant, low-temperature thermal oxidizer, antistatic agent and polypropylene to the first fusion product, and carry out the second fusion at 190° C. for 10 minutes. Add corn modified starch, microbial preparations and propylene glycol to the second fusion product, carry out the third fusion at 110° C., and then inject the product obtained through the fusion.

[0026] In the raw materials for the preparation of environmentally friendly plastic additives, the percentages by weight of each component in the total weight of the additive are: 10% of low-density polyethylene (abbreviated as LDPE), 12% of calcium carbonate with a particle size of 6000-9000 mesh, sarrin resin (English Surlyn) 2%, high-density polyethylene (English abbreviation HDPE) 10%, lubricant 5%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com