Water-free oil-free microbial fertilizer coating additive and microbial fertilizer and application thereof

A microbial coating and microbial technology, applied in the direction of fertilizer mixture, application, organic fertilizer, etc., can solve the problems that affect the efficiency and stability of the product, product packaging, transshipment, inconvenient use, and affect the appearance of the product. The effect of film forming area and coating rate, improvement of micro-ecological environment, and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

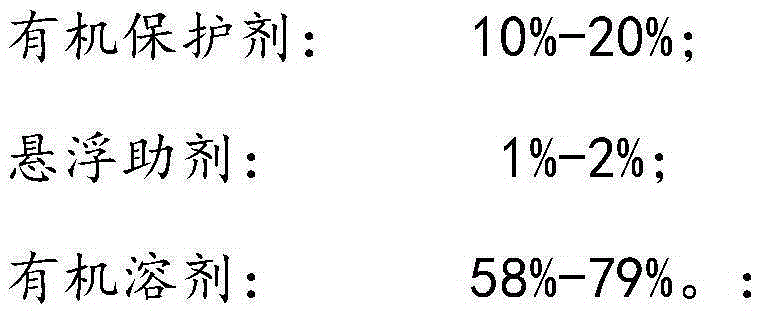

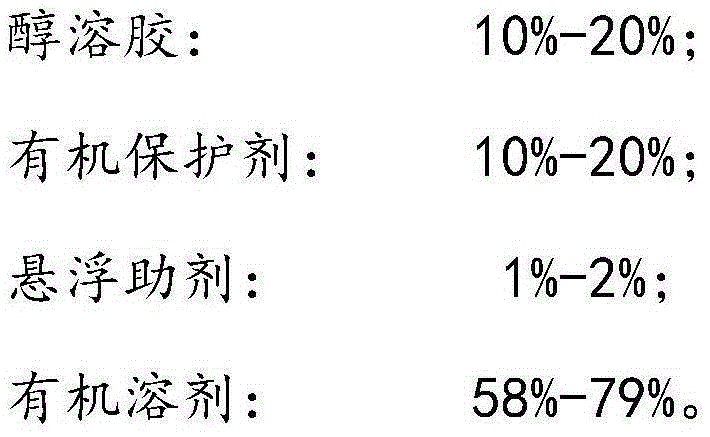

[0032] 1. Preparation of coating aids:

[0033]10% of modified alkyd resin, 20% of soluble starch (potato powder), 1% of formamide and 69% of absolute ethanol are selected by weight, and the mixture is stirred evenly after mixing.

[0034] 2. Preparation of microbial fertilizers;

[0035] Put 1000kg of fertilizer granules into the material bucket of the coating machine, then mix 4kg of the above-mentioned coating aid and 10kg of microbial agent to make a slurry, put it into the spray system of the coating machine, and put it under the condition of 20-60°C The above-mentioned mixed slurry is sprayed on the fertilizer granules to make it form a film and evenly cover the surface of the fertilizer granules, and then stay in the material bucket for 5 minutes.

Embodiment 2

[0037] 1. Preparation of coating aids:

[0038] Select thermoplastic phenolic resin 13%; soluble starch (sweet potato powder) 14%; formamide 1%; dehydrated alcohol 72% by weight, mix and stir evenly.

[0039] 2. Preparation of microbial fertilizers;

[0040] Put 1000kg of fertilizer granules into the material barrel of the coating machine, then mix 4kg of the above-mentioned coating aid and 6kg of microbial agent to make a slurry, put it into the spray system of the coating machine, and put it under the condition of 20-60°C The above-mentioned mixed slurry is sprayed on the fertilizer granules to make it form a film and evenly cover the surface of the fertilizer granules, and then stay in the material bucket for 5 minutes.

Embodiment 3

[0042] 1. Preparation of coating aids:

[0043] Select 20% of urea-formaldehyde resin in parts by weight; 20% of powder prepared from fermented liquid after amino acid extraction; 2% of formamide; 58% of absolute ethanol, mix and stir evenly.

[0044] 2. Preparation of microbial fertilizers;

[0045] Put 1000kg of fertilizer granules into the material bucket of the coating machine, then mix 4kg of the above-mentioned coating aid and 8kg of microbial agent to make a slurry, put it into the spray system of the coating machine, and put it under the condition of 20-60°C The above-mentioned mixed slurry is sprayed on the fertilizer granules to make it form a film and evenly cover the surface of the fertilizer granules, and then stay in the material bucket for 5 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com