A method of freezing and concentrating coal chemical industry wastewater

A coal chemical wastewater, freeze concentration technology, applied in the direction of frozen water/sewage treatment, chemical instruments and methods, filtration treatment, etc., can solve the problems of difficult separation, introduction of refrigerant, difficult control of ice crystal formation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

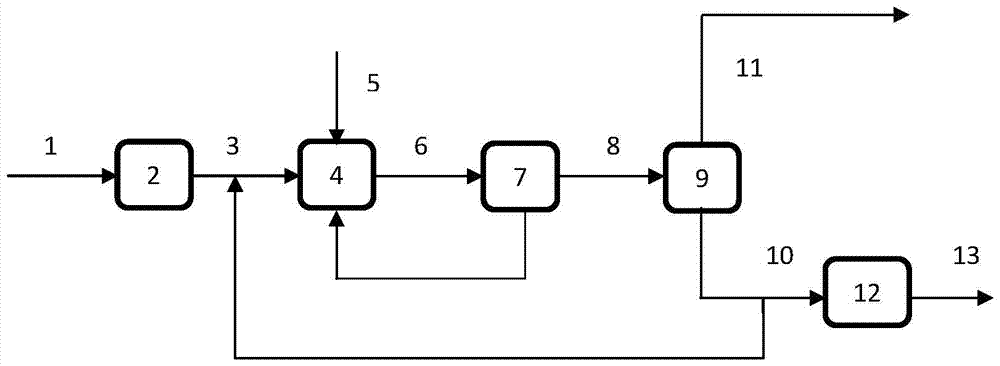

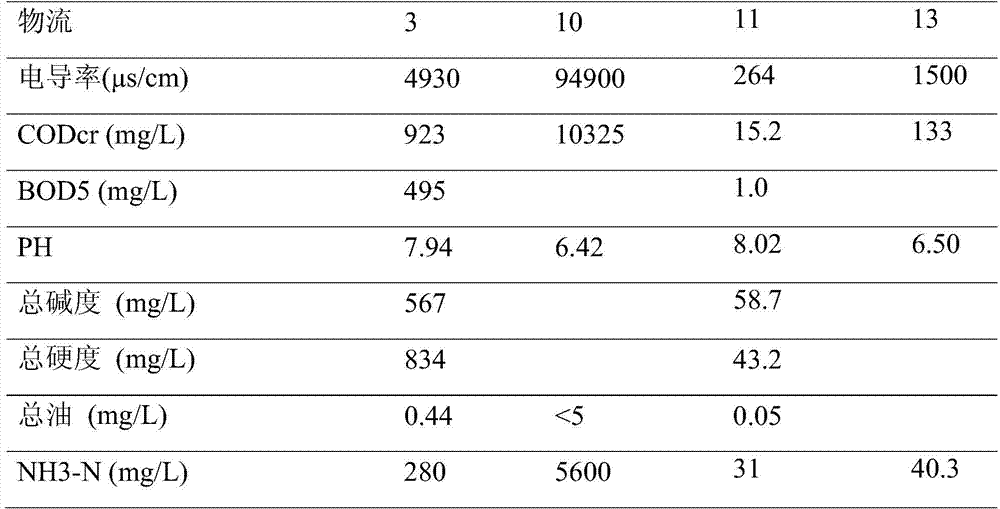

[0038] The 30000kg / h coal-water slurry gasification black water 1 from the upstream unit is filtered 2, cooled down to 15°C; mixed with the wastewater concentrate from the bottom, and sent to the heat exchanger 4 as the feed 3 to be mixed with the refrigerant 5. Heat exchange; the temperature of the heat exchanger is -22°C. After the heat exchange, the ice slurry 6 containing small ice crystals is sent to the recrystallizer 7 to make the ice crystals grow up and be purified; 7. Carry out cyclic material exchange; during the cyclic exchange process, the ice crystals gradually grow and the number of ice crystals gradually increases; through the pressure change in the cleaning tower 9, the pressure variation range is 0 to 4bar, after the ice slurry 8 is sucked into the cleaning tower 9 Squeeze to separate the ice crystals from the concentrate. After cleaning and melting the ice crystals at the top of the cleaning tower, discharge 28,500 kg / h of regenerated water 11 (the ratio of t...

Embodiment 2

[0043]The 30000kg / h Lurgi gasified black water 1 from the upstream unit is filtered 2 and then cooled to room temperature; after being mixed with the concentrated liquid from the bottom, it is sent as feed 3 to the heat exchanger 4 to exchange heat with the refrigerant 5; The temperature of the heat exchanger is -20°C. After the heat exchange, the ice slurry 6 containing small ice crystals is sent to the recrystallizer 7 to make the ice crystals grow up and be purified; the ice slurry is circulated and exchanged between the heat exchanger 4 and the recrystallizer 7 ; During the circulation and exchange process, the ice crystals grow gradually and the number of ice crystals gradually increases; through the pressure change in the cleaning tower 9, the pressure variation range is 0 to 3.5 bar, the ice slurry 8 is sucked into the cleaning tower 9 and squeezed, so that The ice crystals are separated from the concentrated solution, and the 28636kg / h regenerated water 11 is discharged...

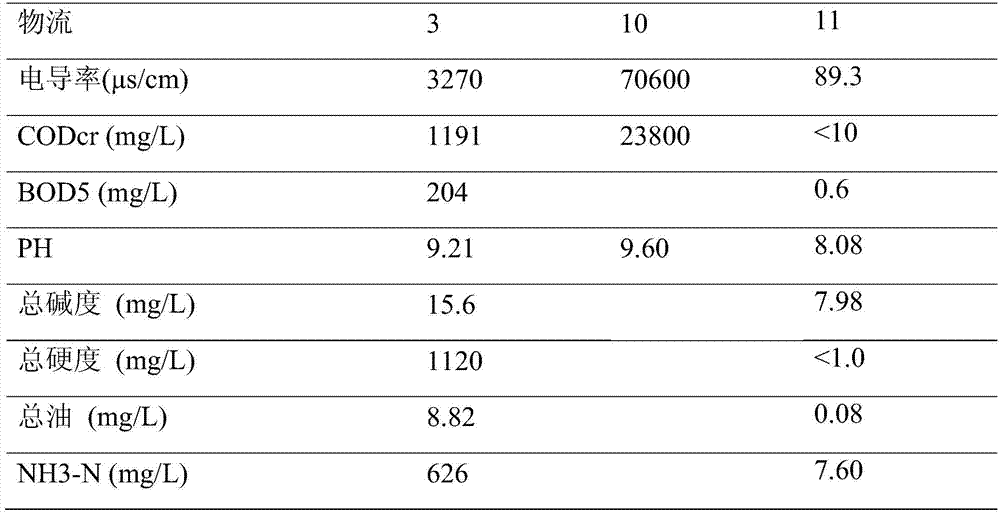

Embodiment 3

[0048] 30000kg / h Fischer-Tropsch synthetic water from upstream unit 1 Add 150kg / h Ca(OH) in pretreatment unit 2 2 After neutralization, the pH value is 6.91, mixed with the concentrated liquid from the bottom as feed 3, feed 3 is sent to heat exchanger 4 to exchange heat with refrigerant 5, and the temperature of heat exchanger is -26°C; heat exchange Finally, the ice slurry 6 containing small ice crystals is sent to the recrystallizer 7 to make the ice crystals grow up and be purified; the ice slurry is circulated and exchanged at the heat exchanger 4 and the recrystallizer 7; during the circulation exchange process, the ice crystals gradually The number of grown ice crystals gradually increases; through the pressure change in the cleaning tower 9, the pressure range is 0-4.0bar, the ice slurry 8 is sucked into the cleaning tower 9 and squeezed, so that the ice crystals and the concentrated solution are separated, and the ice crystals are cleaned and melted. Discharge 26000kg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com