Usage of manganese dioxide coated carbon particle dielectric materials as electromagnetic wave absorption materials

A technology of manganese dioxide and dielectric materials, applied in the field of wave absorbing materials, can solve problems that have not yet been found, and achieve the effects of low production cost, improved loss performance, and improved surface impedance matching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

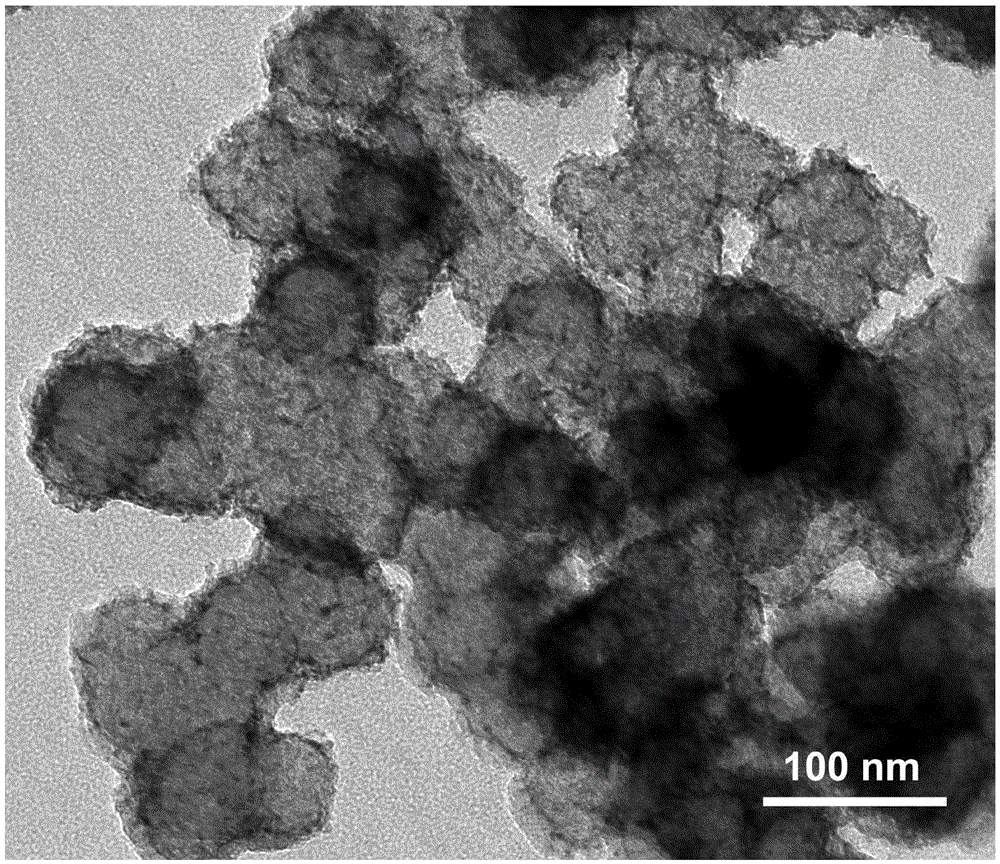

[0032] Add 0.1 g of carbon black particles with a diameter of 50 nm into a mixed solution of sodium dodecylbenzenesulfonate and 10% concentration of dilute hydrochloric acid at a mass ratio of 1:10 for ultrasonic treatment for 1 hour, and then use absolute ethanol and deionized water Each was washed 3 times. Filter the carbon black and add it to 50ml deionized water for 2 hours to form a suspension;

[0033] Get 0.3 g of potassium permanganate and add it into the suspension of the above-mentioned carbon black, and stir for 6 hours;

[0034] The above mixed solution was transferred to a constant temperature water bath, and kept at 80°C for 6 hours;

[0035] After the reaction was completed, the obtained precipitate was filtered and washed three times with deionized water and absolute ethanol, and then dried at 100° C. for 8 hours to obtain a manganese dioxide-coated carbon black composite powder.

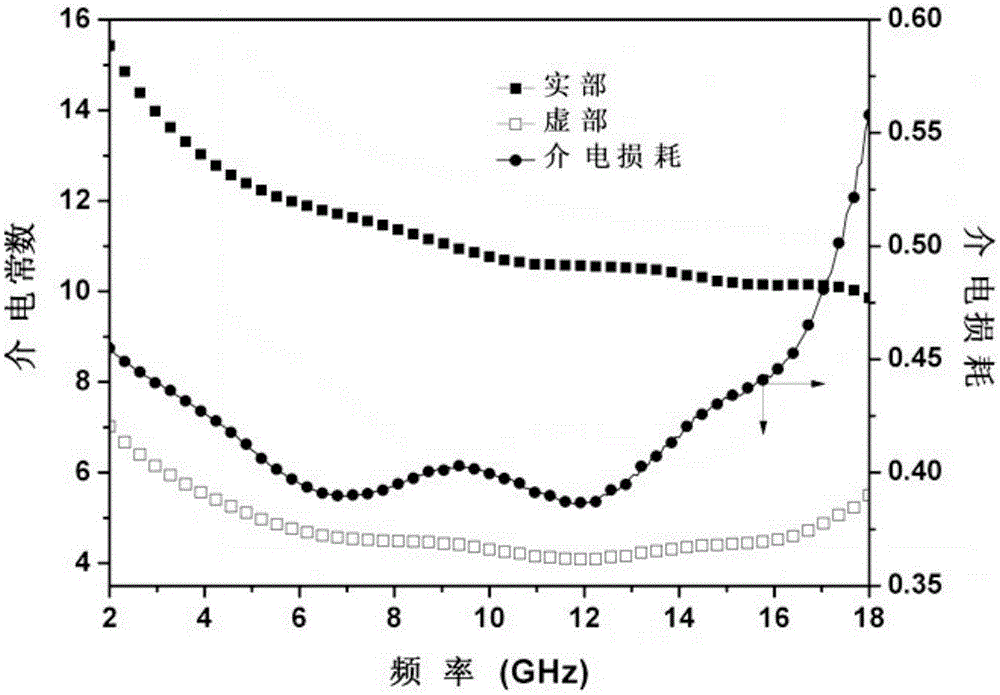

[0036] The above-mentioned manganese dioxide-coated carbon black composite pow...

Embodiment 2

[0041] Add 0.1 g of carbon black particles with a diameter of 100 nm into a mixed solution of sodium dodecylbenzenesulfonate and 10% concentration of dilute hydrochloric acid in a mass ratio of 1:10 for ultrasonic treatment for 2 hours, and then use absolute ethanol and deionized water Wash each for 3 times, filter and add to 100ml deionized water for ultrasonication for 2 hours, so that the carbon black particles are evenly dispersed in the water to form a stable suspension;

[0042] Get potassium permanganate 0.6g and join in the suspension of above-mentioned carbon black, stir 3 hours;

[0043] The above mixed solution was transferred to a constant temperature water bath, and kept at 80°C for 12 hours;

[0044] After the reaction was completed, the obtained precipitate was filtered and washed three times with deionized water and absolute ethanol, and then dried at 100° C. for 8 hours to obtain a manganese dioxide-coated carbon black composite powder.

[0045] The above-men...

Embodiment 3

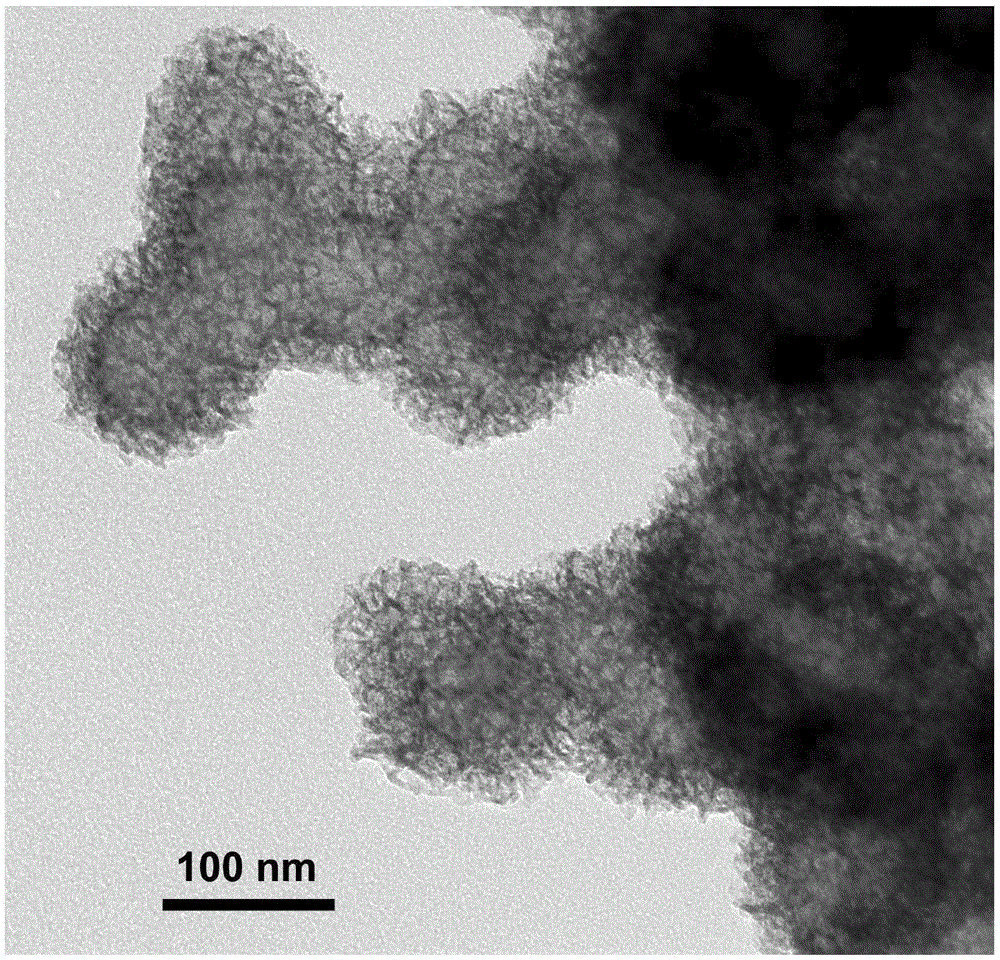

[0050] Add 0.1 g of carbon sphere particles with a diameter of 300 nm to a mixed solution of sodium dodecylbenzenesulfonate and 10% concentration of dilute hydrochloric acid at a mass ratio of 1:10 for ultrasonic treatment for 1 hour, and then use absolute ethanol and deionized water Each was washed 3 times. After filtering the carbon spheres, add them to 50ml deionized water and sonicate for 2 hours to form a suspension;

[0051] Take 0.6 g of potassium permanganate and add it to the above suspension, and stir for 6 hours;

[0052] The above mixed solution was transferred to a constant temperature water bath, and kept at 90°C for 6 hours;

[0053] After the reaction is completed, the obtained precipitate is filtered and washed three times with deionized water and absolute ethanol respectively, and then dried at 100° C. for 8 hours to obtain a manganese dioxide-coated carbon sphere composite powder.

[0054] The above-mentioned manganese dioxide-coated carbon black composite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com