Toluidine blue modified metal organic framework electrode and preparation method and application thereof

A technology of metal-organic framework and toluidine blue, which is applied in electrolytic organic material coating, material electrochemical variable, material analysis through electromagnetic means, etc., can solve the problems of high raw material price and high detection limit, and achieve simple method and electrochemical Good performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

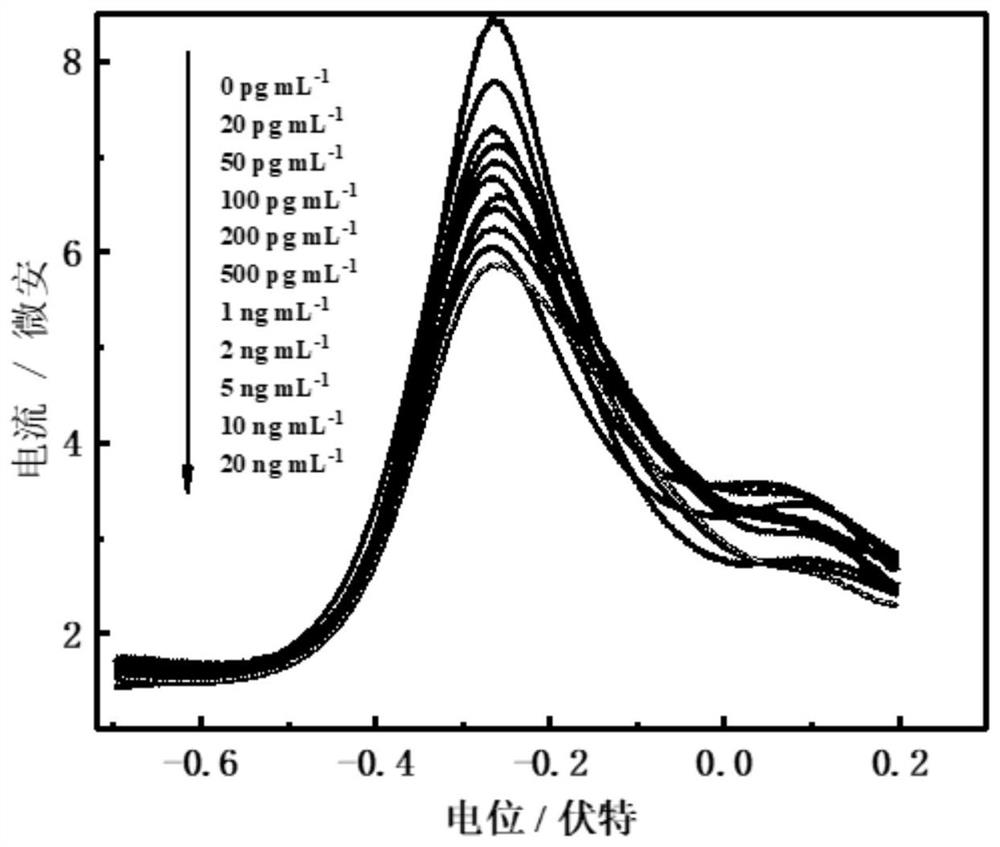

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041]Dissolve 0.266 g of zinc nitrate hexahydrate (0.0009 mol) in 3 mL of distilled water to obtain a 0.089 g / mol zinc nitrate aqueous solution, and add 0.0303 g of potassium nitrate (0.0003 mol) as a supporting electrolyte. Dissolve 0.105 g of trimesic acid (0.0005 mol) in 3 mL of ethanol, add the resulting 0.035 g / mL trimesic acid ethanol solution into zinc nitrate aqueous solution and mix well, add 300 µL of 0.025 mol / L toluidine blue The aqueous solution was stirred at room temperature at a speed of 400 r / min for 3 hours to obtain an electrodeposition solution. The toluidine blue aqueous solution is prepared by dissolving toluidine blue in 0.1mol / L nitric acid.

[0042] Glassy carbon electrodes (GCE for short) with a radius of 3 mm were ground and polished successively in 0.5 and 0.05 µm alumina suspensions, the electrode surface was cleaned with ultrapure water, and ultrasonic waves were used for 3 times in ultrapure water, ethanol, and ultrapure water respectively. min...

Embodiment 2

[0050] Dissolve 0.5 g of zinc nitrate hexahydrate (0.0017 mol) in 5 mL of distilled water to obtain a 0.1 g / mol zinc nitrate aqueous solution, and add 0.0303 g of potassium nitrate (0.0003 mol) as a supporting electrolyte. Dissolve 0.2 g of trimesic acid (0.0010 mol) in 5 mL of ethanol, and add the obtained 0.04 g / mL trimesic acid ethanol solution into the zinc nitrate aqueous solution and mix well, add 500 µL of 0.02 mol / L toluidine The blue aqueous solution was stirred at room temperature at a speed of 350 r / min for 3.5 h to obtain an electrodeposition solution. The toluidine blue aqueous solution is prepared by dissolving toluidine blue in 0.5mol / L nitric acid.

[0051] A glassy carbon electrode (GCE) with a radius of 2 mm was ground and polished successively in 1.0 µm and 0.05 µm alumina suspensions, the surface of the electrode was cleaned with ultrapure water, and ultrasonic waves were used in ultrapure water, ethanol, and ultrapure water for 2 min to remove residual al...

Embodiment 3

[0055] Dissolve 0.8 g of zinc nitrate hexahydrate (0.0027 mol) in 5 mL of distilled water to obtain a 0.16 g / mol zinc nitrate aqueous solution, and add 0.0606 g of potassium nitrate (0.0006 mol) as a supporting electrolyte. Dissolve 0.5 g of trimesic acid (0.0024 mol) in 5 mL of ethanol, and add the obtained 0.1 g / mL trimesic acid ethanol solution into the zinc nitrate aqueous solution and mix well, add 600 µL of 0.025 mol / L toluidine The blue aqueous solution was stirred at room temperature at a speed of 500 r / min for 2.5 h to obtain an electrodeposition solution. The toluidine blue aqueous solution is prepared by dissolving toluidine blue in 0.2mol / L nitric acid.

[0056] A glassy carbon electrode (GCE) with a radius of 2 mm was ground and polished successively in 1.0 µm and 0.03 µm alumina suspensions, the surface of the electrode was cleaned with ultrapure water, and ultrasonic waves were used in ultrapure water, ethanol, and ultrapure water for 5 min to remove residual a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com