Technology for producing automotive trim materials through non-woven waste and leftover materials

A technology for automobile interior decoration and leftover materials, which is applied in the direction of motor vehicles, textiles, papermaking, non-woven fabrics, etc., to achieve the effects of reducing product costs, saving resources, and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

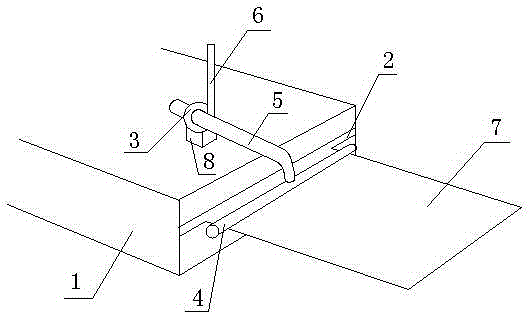

Image

Examples

Embodiment 1

[0031] At present, in the production process of non-woven fabrics, a large amount of scrap non-woven materials are produced due to cutting, and a large amount of waste non-woven materials are also produced in the process of use. The technology of interior materials is aimed at effectively utilizing non-woven waste and leftover materials to produce environmentally friendly automobile interior materials. It is used to replace non-environmentally friendly sound-absorbing layer materials for automotive interiors such as asphalt boards, glass brazing sheets, and rubber sheets. It can effectively remove moisture during the manufacturing process, and prevent the materials from mildew due to high water content during later storage and use. For example, side decoration Provide excellent drying and molding conditions for certain materials such as parts, carpet bases, wheel covers, etc. that require post-baking and compression molding.

[0032] The process of using non-woven waste and le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com