Non-resin type profile control agent and application thereof in petroleum exploitation process

A technology of profile control agent and resin type, which is applied in the field of non-resin type profile control agent and its application in the process of oil exploitation, and can solve the problems of poor application effect of oily sludge profile control agent and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

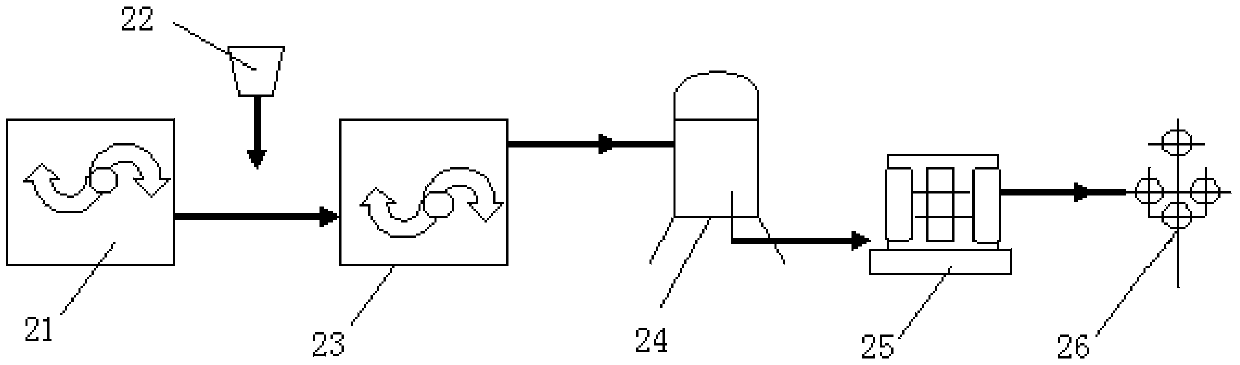

[0036] The preparation process of profile control agent is as follows: figure 2 As shown, the specific process is as follows: implementation steps: the oily sludge is transported to the profile control well site collection tank 21, and the dispersant, optional retarder and curing agent are added to the oily sludge, and fully stirred evenly in the mixing tank 23, while injecting water for dilution and aging. After the prepared oily sludge profile control agent is filtered through the filter 24 to remove large particle impurities, it is pumped into the water injection well 26 by the hydraulic reinjection pump 25 .

[0037] During the injection of the profile control agent, the injection pump is preferably a TPB hydraulic profile control injection pump. The TPB hydraulic profile control injection pump converts the high-speed rotating mechanical energy of the motor into the pressure energy of the hydraulic oil through the constant power variable oil pump, and then converts the p...

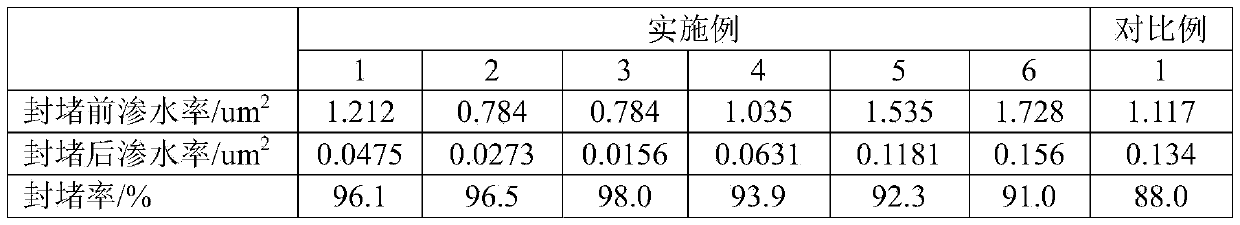

Embodiment 1

[0053] In this embodiment, the oily sludge is first prepared into the first suspension slurry with a suspended matter concentration of 12wt%, which consists of 0.2% sodium dodecylsulfonate (emulsifier), 0.2% polyacrylamide (suspension agent) ). The first profile control agent is prepared by using the first suspension slurry.

[0054] In this embodiment, the oily sludge is first prepared into the second suspension slurry with a suspended matter concentration of 10wt%, which consists of 0.1% sodium dodecylsulfonate (emulsifier), 0.1% polyacrylamide (suspension agent) ). The second profile control agent and the third profile control agent are prepared by using the second suspension slurry.

[0055] Three-slug profile control technology is adopted. The first profile control agent comprises the oily sludge of 3g, sodium hexametaphosphate (dispersant) of 0.15g, sodium silicate (solidifying agent) of 0.5g, sodium dodecylsulfonate (emulsifying agent) of 0.05g, 0.05g of polyacrylam...

Embodiment 2

[0057]In this embodiment, the oily sludge is first prepared into the first suspension slurry with a suspended matter concentration of 10wt%, which consists of 0.25% sodium dodecylsulfonate (emulsifier), 0.25% polyacrylamide (suspension agent) ). The first profile control agent is prepared by using the first suspension slurry.

[0058] In this embodiment, the oily sludge is first prepared into the second suspension slurry with a suspended matter concentration of 20wt%, which consists of 0.375% sodium dodecylsulfonate (emulsifier), 0.25% polyacrylamide (suspension agent) ). The second profile control agent is prepared by using the second suspension slurry.

[0059] In this embodiment, the oily sludge is first prepared into the third suspension slurry with a suspended matter concentration of 20wt%, which consists of 0.2% sodium dodecylsulfonate (emulsifier), 0.34% polyacrylamide (suspension agent) ). The third profile control agent is prepared by using the third suspension sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com