A kind of anti-corrosion environmental protection coating material for metal and preparation method thereof

A coating material and anti-corrosion technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of poor barrier performance of water-based epoxy anti-corrosion coatings, failure to achieve complementary effects of modification, poor compatibility, etc., to eliminate the decline in anti-corrosion effects, Simplified painting process and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with specific examples.

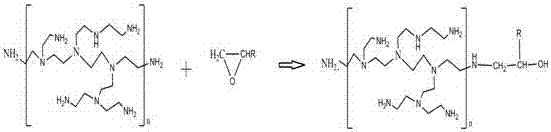

[0023] see figure 1 , figure 2 , the present embodiment provides an anti-corrosion and environmental protection coating material 1 for metal, which is composed of two kinds of organic nano-microspheres 2 modified by PEI and water-based epoxy resin; the organic nano-microspheres 3 are PMMA nano-microspheres and PS nanospheres.

[0024] This embodiment also provides a method for preparing an anti-corrosion and environment-friendly coating material for metal, which includes the following steps.

[0025] Step 1. Weigh 0.2 g of initiator potassium persulfate kps (refined), stir and dissolve in 60 ml of distilled water, then add 40 g of methyl methacrylate MMA (refined) into a three-necked flask at the same time, and then add 200 ml of distilled water , stirred rapidly under the protection of nitrogen for 30 min at a stirring speed of 300 r / min, and then transferred to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com