High-temperature-resistant anti-corrosion coating for power distribution system and preparation technology of coating

A technology for anti-corrosion coatings and power distribution systems, applied in anti-corrosion coatings, anti-fouling/underwater coatings, coatings, etc., can solve problems such as potential safety hazards, easy corrosion of cables, and short service life. Simple and feasible, long service life and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A high-temperature-resistant and anti-corrosion coating for power distribution systems, which is prepared from the following raw materials in parts by weight:

[0021] 8 parts of triethanolamine oleic acid soap, 7 parts of dimethyl phthalate, 6 parts of n-butanol, 5 parts of emulsified silicone oil, 3 parts of lithium bentonite, 2 parts of sodium citrate, 2 parts of isobornyl acetate, camphor 2 parts oil, 1 part sodium silicate, 1 part aluminum nitride, 1 part tobacco extract and 1 part fennel extract.

[0022] The particle diameters of the lithium-based bentonite, sodium citrate and aluminum nitride are all controlled at 500 mesh; the modulus n of the sodium water glass is 2.8.

[0023] It is prepared according to the following process:

[0024] 1) Preparation of tobacco extract: dry the tobacco so that the water content is lower than 10% (weight fraction), then add twice the weight of 70% (volume fraction) ethanol to reflux for extraction for 1 hour, collect the extr...

Embodiment 2

[0030] A high-temperature-resistant and anti-corrosion coating for power distribution systems, which is prepared from the following raw materials in parts by weight:

[0031] 10 parts of triethanolamine oleic acid soap, 8 parts of dimethyl phthalate, 7 parts of n-butanol, 6 parts of emulsified silicone oil, 4 parts of lithium bentonite, 3 parts of sodium citrate, 3 parts of isobornyl acetate, camphor 3 parts oil, 2 parts sodium silicate, 2 parts aluminum nitride, 2 parts tobacco extract and 2 parts fennel extract.

[0032] The particle diameters of the lithium-based bentonite, sodium citrate and aluminum nitride are all controlled at 500 mesh; the modulus n of the sodium water glass is 2.8.

[0033] It is prepared according to the following process:

[0034] 1) Preparation of tobacco extract: dry the tobacco so that the water content is lower than 10% (weight fraction), then add twice the weight of 70% (volume fraction) ethanol to reflux for extraction for 1 hour, collect the...

Embodiment 3

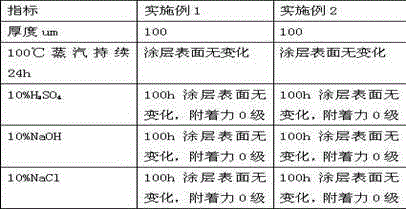

[0040] Taking the cable material as an example, paint the coatings prepared in Example 1 and Example 2 on the outer layer of the cable, and measure the performance parameters of the cable surface, see Table 1 for details:

[0041] Table 1

[0042]

[0043] Conclusion: The coatings prepared in Example 1 and Example 2 of the present invention have better corrosion resistance and high temperature resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com