A kind of tungsten oxide nanowire winding composite material, preparation method and application

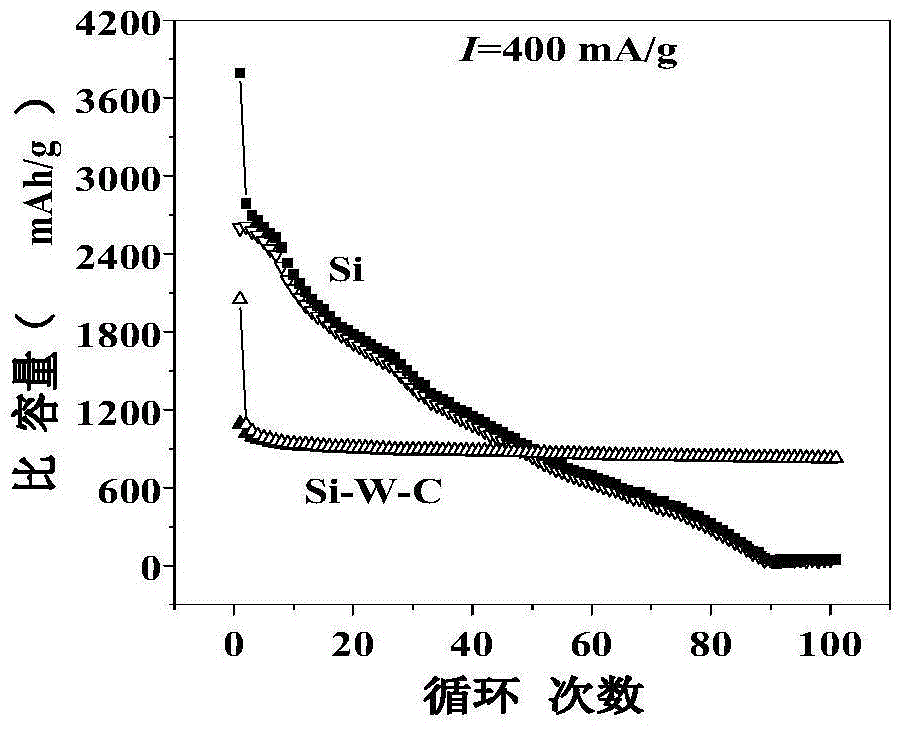

A technology of tungsten oxide nanowires and winding composite materials, which is applied in the field of composite materials, can solve problems such as low conductivity and poor cycle stability of electrodes, and achieve high yield, obvious electrochemical performance, and excellent charge and discharge performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

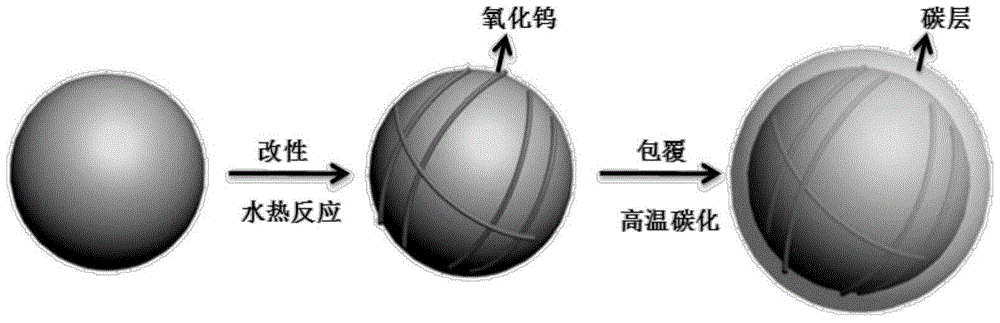

[0033] Configure deionized water and H according to the volume ratio (3 / 1 / 1) 2 o 2 and concentrated H 2 SO 4 500mL of aqueous solution. Disperse the nano-Si powder in it, disperse evenly by ultrasonic, vacuumize, fill with Ar gas protection, and ultrasonic at 60°C for 60min. Filter with suction, wash with deionized water three times, and dry in vacuum.

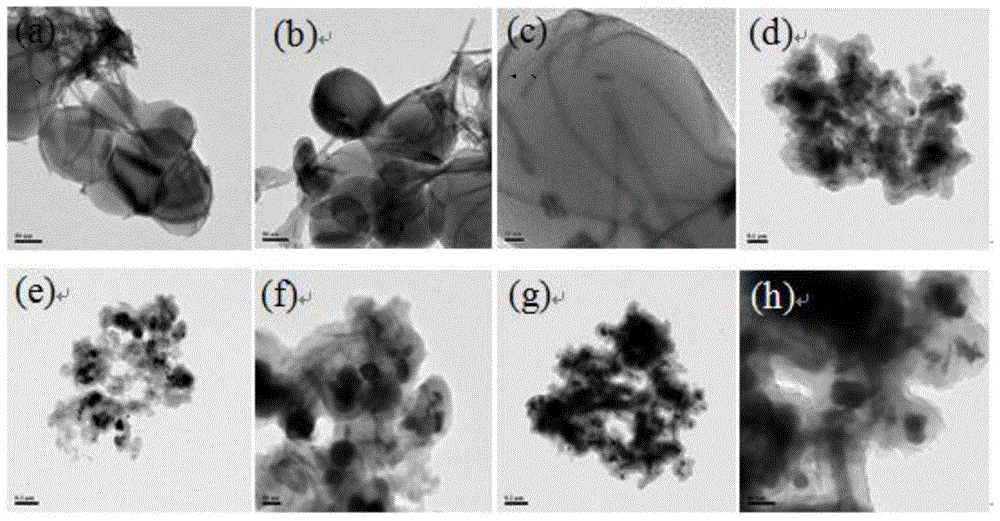

[0034] Take 0.1 g of the above-mentioned hydroxylated and modified nano-Si powder and redisperse it in 30 mL of absolute ethanol, disperse it ultrasonically for 1 h to make it uniformly dispersed, and add a certain amount of WCl 6 , ultrasonically dispersed for 1 h, continued to stir for 6 h, and then transferred to a 50 mL hydrothermal reactor, and reacted at 180 ° C for 24 h. After the reaction, centrifuge, wash with ethanol three times, and dry in vacuum to obtain a Si composite material coated with tungsten oxide nanowires, wherein the mass ratio of tungsten oxide nanowires to Si is about 1:1.5.

[0035] The Si compo...

Embodiment 2

[0039] Prepare two 200mL aqueous solutions containing 1wt.% PDDA and 0.2M NaCl, and disperse them uniformly by ultrasonication for 10 minutes; prepare one 200mL aqueous solution of 1wt.% PSS, and disperse them by ultrasonic dispersion for 10 minutes; 2 Nanoparticles (50nm) were sequentially modified by PDDA-PSS-PDDA, filtered, vacuum-dried at 70°C for 2 hours, ground after drying, and marked for storage.

[0040] Take the above modified SnO 2 Re-disperse 0.25g of nanoparticles in 30mL of absolute ethanol, ultrasonically disperse for 1h to make them uniformly dispersed, add a certain amount of WCl 6 , ultrasonically dispersed for 1 h, continued to stir for 6 h, transferred to a 50 mL hydrothermal reactor, and reacted at 200 ° C for 10 h. After the reaction, centrifuge, wash with ethanol 3 times, and dry in vacuum, the tungsten oxide nanowires and SnO 2 The mass ratio is about 1:5.

[0041] SnO coated with tungsten oxide nanowires 2 The complex was re-dispersed ultrasonicall...

Embodiment 3

[0046] Take 3 g of polyvinylpyrrolidone (PVP, molecular weight: 25000), disperse it in 100 mL of absolute ethanol, and disperse evenly by ultrasonic (sonication for 10 min). Take 1g of zinc ferrite (about 50nm) and disperse in it, stir ultrasonically for 10min until it is evenly dispersed, and seal the mouth. Continue to sonicate for 1h. Filter and dry in vacuum at 70°C for 2h. Prepare PVP modified zinc ferrite after grinding;

[0047] Take 0.2 g of the above-mentioned modified zinc ferrite nanoparticles and redisperse them in 30 mL of absolute ethanol, ultrasonically disperse for 1 h to make them uniformly dispersed, add a certain amount of WCl 6 , ultrasonically dispersed for 1 hour, continued stirring for 6 hours, transferred to a 50 mL hydrothermal reactor, and reacted at 180 ° C for 48 hours. After the reaction, centrifuge, wash with ethanol 3 times, and dry in vacuum, the tungsten oxide nanowires and SnO 2 The mass ratio is about 1:4.

[0048] The zinc ferrite compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com