Passivation protecting structure, light emitting diode and manufacturing method thereof

A technology of light-emitting diodes and protective structures, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of inability to solve adhesion, difficult to implement, and reduce the luminous brightness of LED devices, so as to improve the design quality and luminous brightness, solve the Poor adhesion and the effect of solving poor isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

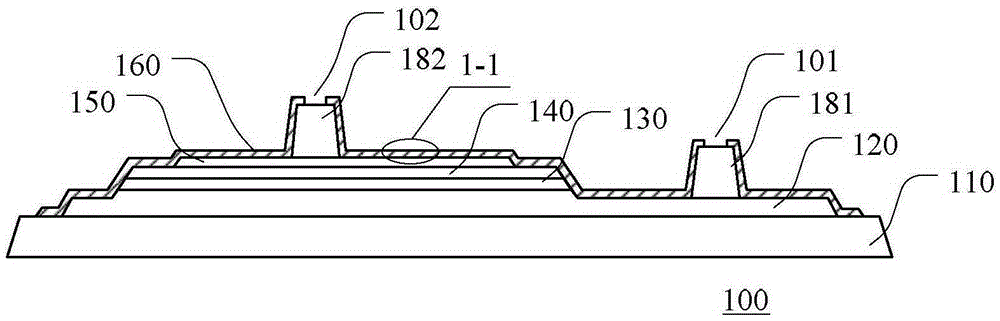

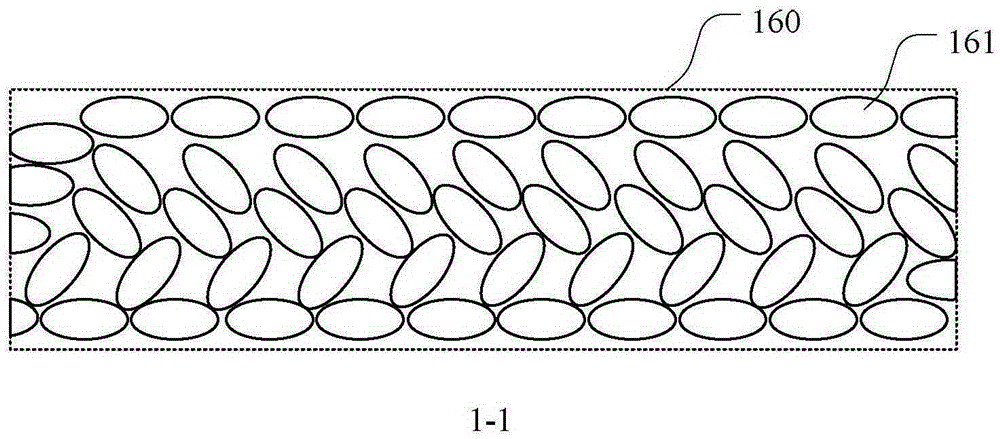

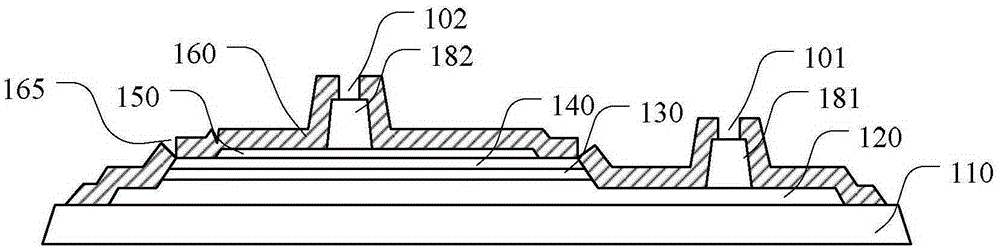

[0059] Various embodiments of the invention will be described in more detail below with reference to the accompanying drawings. In the various drawings, the same elements are denoted by the same or similar reference numerals. For the sake of clarity, various parts in the drawings have not been drawn to scale.

[0060] The passivation protection structure provided by the prior art and the present invention and its manufacturing method will be described in detail below with reference to the accompanying drawings and specific implementation examples. For the convenience of description and understanding, a relatively simple LED device with a front-mounted planar structure after the metal electrodes are fabricated is selected as the object that needs to be fabricated with a passivation protection structure.

[0061] figure 1 and 2 A schematic cross-sectional view and a partially enlarged view of an LED device according to the prior art are respectively shown, wherein, figure 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com