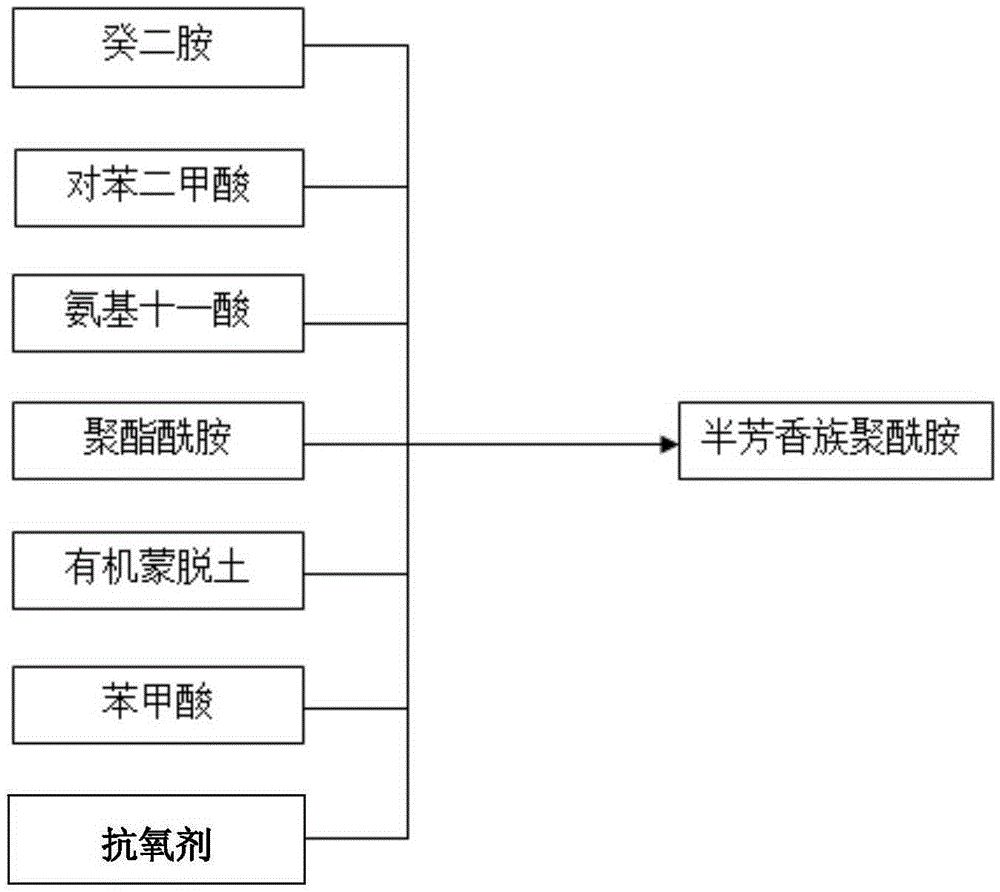

Semi-aromatic polyamide and synthesis method thereof

A semi-aromatic and synthetic method technology, applied in the field of materials, can solve the problems of restricting the large-scale promotion of solid-phase polymerization, accelerating the discharge of by-product small molecules, and many solid-phase polymerization production processes, so as to achieve excellent processing performance, increase productivity, The effect of reducing the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] The raw material composition and synthesis steps of the polyester amide used in this embodiment are as follows:

[0074] (1) The monomer after vacuum drying 2: 1006.6g (5mol) 11-aminoundecanoic acid, 456.6g (4mol) 6-caprolactone, 270.3g (1.25mol) 2,2'-(1,3 -Phenylene)-Dioxazoline was added to the stirred polymerization reactor, while adding 1% of the total weight of monomer 2 to tetrabutyl titanate (17.3g) as a catalyst, and 500mL of water as mass transfer and heat transfer The medium; then vacuum for 5min, nitrogen gas for 5min, so cycle 6 times, so that the reactants exist in the environment under the protection of nitrogen, control the system pressure in the stirred polymerization reactor to 0.2MPa;

[0075] (2) In 2.5 hours, heat the agitated polymerization reactor to 250℃ in an airtight manner and adjust the stirring speed of the agitated polymerization reactor to 40r / min. When the temperature of the agitated polymerization reactor reaches 210℃, vent gas To 1.6MPa, and...

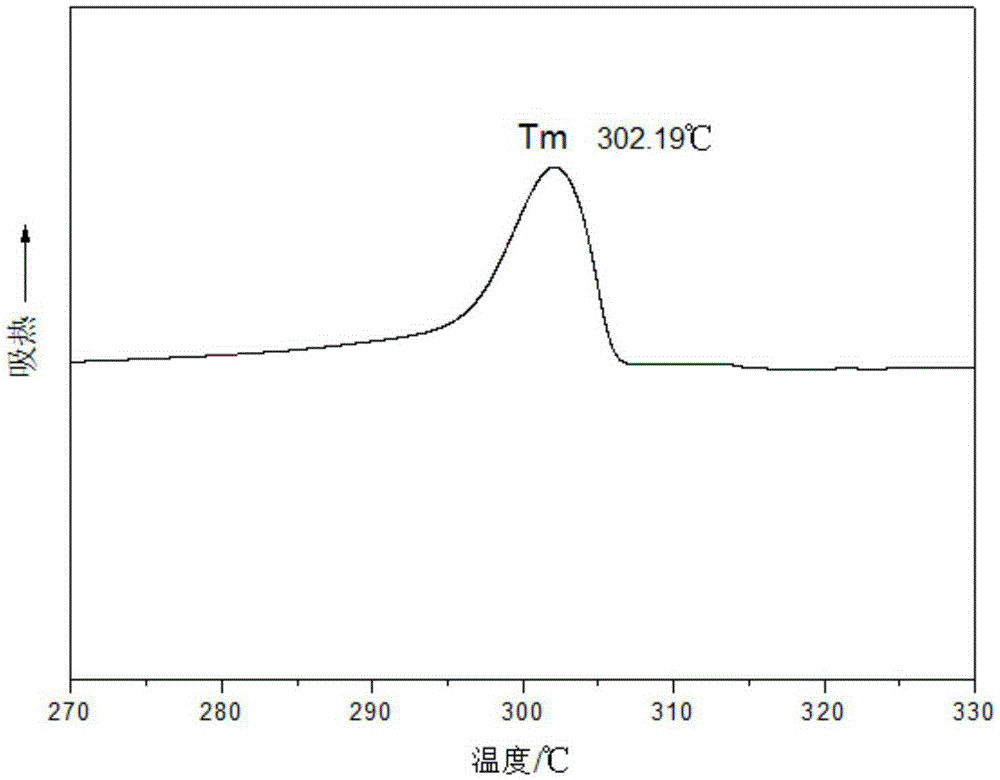

Embodiment 2

[0080] The raw material composition and synthesis steps of the polyester amide used in this example are the same as those in Example 1.

[0081] The method for synthesizing semi-aromatic polyamide in this embodiment includes the following steps:

[0082] (1) Add the vacuum-dried monomer 1:172.3g (1mol) decane diamine, 166.1g (1mol) terephthalic acid, 40.3g (0.2mol) 11-aminoundecanoic acid into the stirred polymerization reactor Add 8% (30.3g) of polyester amide, 8% (30.3g) of organic montmorillonite, 3% (11.4g) of benzoic acid, and 0.3% (1.1g) of N ,N`-bis(2,2,6,6-tetramethyl-4-piperidinyl)-1,3-phthalamide, add 100mL water as the mass and heat transfer medium; then vacuum for 5min, pass Nitrogen for 5 minutes, circulate 6 times in this way so that the stirred polymerization reactor exists in an environment protected by nitrogen, and the system pressure in the stirred polymerization reactor is controlled to 0.2 MPa;

[0083] (2) Within 2 hours, heat the stirred polymerization reacto...

Embodiment 3

[0085] The raw material composition and synthesis steps of the polyester amide used in this example are the same as those in Example 1.

[0086] The method for synthesizing semi-aromatic polyamide in this embodiment includes the following steps:

[0087] (1) Add the vacuum-dried monomer 1:172.3g (1mol) decanediamine, 166.1g (1mol) terephthalic acid, 20.1g (0.1mol) 11-aminoundecanoic acid into the stirred polymerization reactor Add 2% (7.2g) of polyester amide, 0.5% (1.8g) of organic montmorillonite, 0.5% (1.8g) of benzoic acid, and 0.2% (0.7g) of N ,N`-bis(2,2,6,6-tetramethyl-4-piperidinyl)-1,3-phthalamide, add 100mL water as the mass and heat transfer medium; then vacuum for 5min, pass Nitrogen is applied for 5 minutes and circulates 6 times in this way, so that the reactants exist in the environment under the protection of nitrogen, and the system pressure in the stirred polymerization reactor is controlled to 0.3MPa;

[0088] (2) In 3.5 hours, heat the stirred polymerization rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com