Novel copolyster hot melt adhesive and preparation method thereof

A technology of copolyester and hot melt adhesive, which is applied in the directions of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problem that the dry cleaning resistance needs to be improved, and achieve the effect of improving the dry cleaning resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

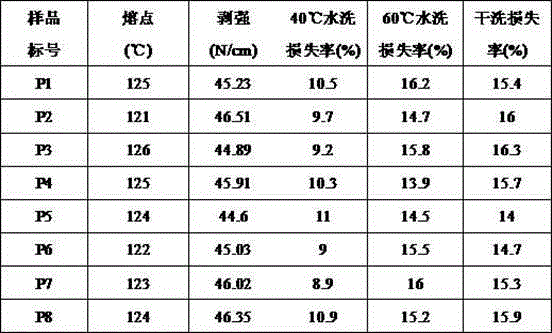

Examples

Embodiment 1

[0024] New copolyester hot melt adhesive, the raw material composition includes: bisphenol A56.544g, maleic acid 26.912g, terephthalic acid 166g, 1,6-adipic acid 29.2g, 1,4-butanediol 120.06 g, 35.416 g of 1,3-propanediol, 0.0996 g of monobutyl stannate, 0.0996 g of tetrabutyl titanate, and 0.0498 g of triphenyl phosphite.

[0025] The preparation method of novel copolyester hot-melt adhesive, the steps are as follows:

[0026] (1) Add 56.544g of bisphenol A, 26.912g of maleic acid, and 0.0996g of monobutylstannoic acid into a reaction kettle with a stirrer, and slowly raise the temperature to 160°C~170°C, at a pressure of -0.09 Reaction under reduced pressure for 3.0 hours at MPa~-0.1MPa to obtain prepolymer;

[0027] (2) The obtained prepolymer, 166g of terephthalic acid, 29.2g of 1,6-adipic acid, 120.06g of 1,4-butanediol, 35.416g of 1,3-propanediol, and tetrabutyl titanate 0.0996g, put it into the reaction kettle with agitator, raise the temperature to 190℃~200℃ under th...

Embodiment 2

[0031] New copolyester hot melt adhesive, the raw material composition includes: bisphenol A70.908g, maleic acid 34.394g, terephthalic acid 166g, 1,6-adipic acid 51.1g, 1,4-butanediol 151.875 g, 25.65 g of 1,3-propanediol, 0.083 g of monobutyl stannate, 0.083 g of tetrabutyl titanate, and 0.083 g of triphenyl phosphite.

[0032] The preparation method of novel copolyester hot-melt adhesive, the steps are as follows:

[0033] (1) Add 70.908g of bisphenol A, 34.394g of maleic acid, and 0.083g of monobutylstannic acid into a reaction kettle with a stirrer, and slowly raise the temperature to 160°C~170°C. 0.09MPa~-0.1MPa under reduced pressure for 3.0h to obtain prepolymer;

[0034] (2) The obtained prepolymer, 166g of terephthalic acid, 51.1g of 1,6-adipic acid, 151.875g of 1,4-butanediol, 25.65g of 1,3-propylene glycol, and tetrabutyl titanate 0.083g, put it into the reaction kettle with agitator, raise the temperature to 190℃~200℃ under the protection of nitrogen, when the sy...

Embodiment 3

[0038] New copolyester hot melt adhesive, the raw material composition includes: bisphenol A91.428g, maleic acid40.484g, terephthalic acid166g, 1,6-adipic acid73g, 1,4-butanediol168.75 g, 23.25 g of ethylene glycol, 0.0664 g of monobutyl stannate, 0.0664 g of tetrabutyl titanate, and 0.0996 g of triphenyl phosphite.

[0039] The preparation method of novel copolyester hot-melt adhesive, the steps are as follows:

[0040] (1) Add 1.428g of bisphenol A, 40.484g of maleic acid, and 0.0664g of monobutylstannoic acid into a reaction kettle with a stirrer, and slowly raise the temperature to 160°C~170°C. 0.09MPa~-0.1MPa under reduced pressure for 3.0h to obtain prepolymer;

[0041] (2) The obtained prepolymer, 166g of terephthalic acid, 73g of 1,6-adipic acid, 168.75g of 1,4-butanediol, 23.25g of ethylene glycol, and 0.0664g of tetrabutyl titanate, Add it into a reaction kettle with a stirrer, raise the temperature to 190°C~200°C under the protection of nitrogen, when the system h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com