A nanobubble generator and applications thereof

A nano-bubble and generator technology, applied in water aeration, sustainable biological treatment, chemical instruments and methods, etc., to achieve the effect of improving crushing efficiency, increasing contact area, and improving treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

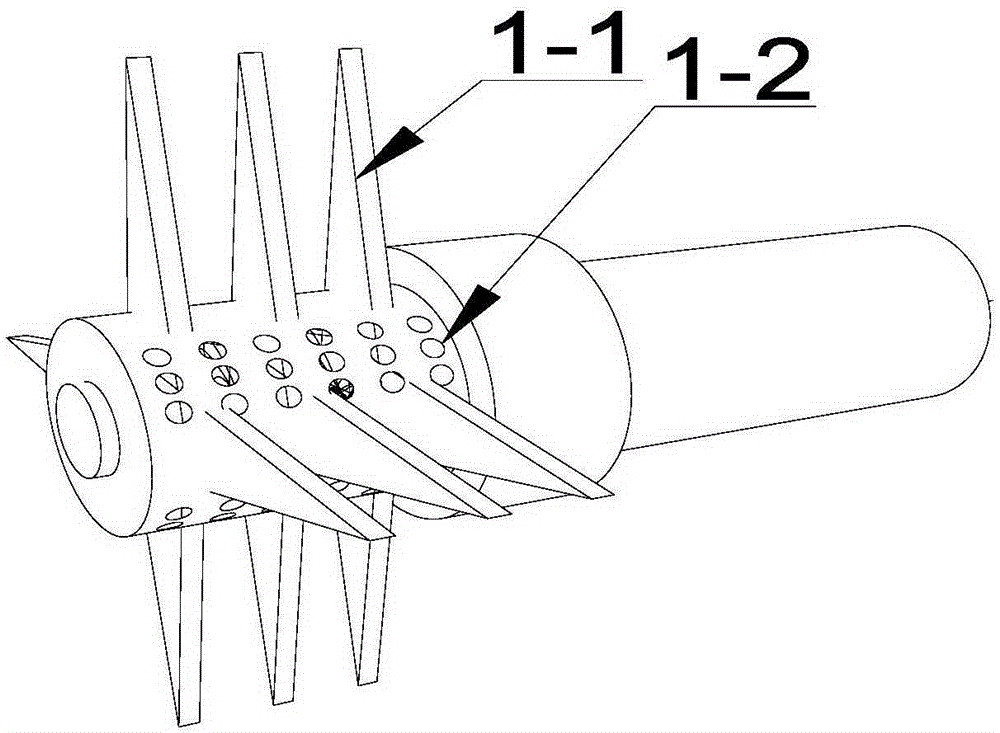

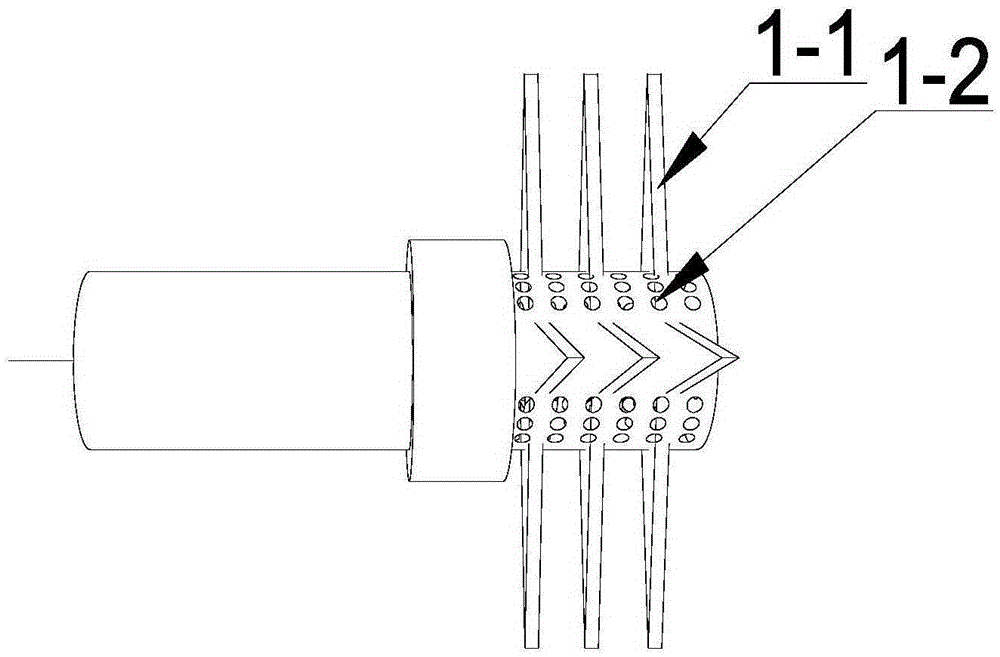

[0042] Such as figure 1 and figure 2 Shown, be laboratory carbon tetrachloride separation processing system structural representation and nano-bubble generator structural representation, as can be seen from the figure, described nano-bubble generator 1 is placed in the exposure of laboratory carbon tetrachloride separation processing system In the gas reaction box 2, it is divided into a high-speed rotor impeller 1-1, a microporous aeration head 1-2 and an air inlet pipe 1-3, wherein the microporous aerator head 1-2 is located in the air inlet pipe 1-3 At one end of the exhaust port, the high-speed rotor impeller 1-1 is arranged on the air inlet pipe 1-3. The high-speed rotor impellers 1-1 and the microporous aeration heads 1-2 are arranged alternately, and the high-speed rotor impellers 1-1 are provided with three groups, each group has four impellers, the rotation of the impellers is symmetrical, and the high-speed rotor impellers 1-1 For the airfoil type. Such as imag...

Embodiment 2

[0044] Adopt the laboratory carbon tetrachloride separation treatment system that is provided with the nano-bubble generator described in embodiment 1 to process the laboratory raffinate containing carbon tetrachloride, at first, the carbon tetrachloride raffinate is passed through raffinate inlet pipe 6 enters the aeration reaction box 2, and at the same time, the hydrogen peroxide reaction reagent enters the aeration reaction box 2 through the hydrogen peroxide filling pipe 6-1, and reacts with the carbon tetrachloride residual liquid; at the same time, the outside air enters through the air inlet pipe 1-3 Nano-bubble generator 1, the high-speed rotor impeller 1-1 rotates at a speed of 3000-9000 rpm, crushing the micro-bubbles generated by the microporous aeration head 1-2 into bubbles with a diameter of 10-600 nanometers, uniformly Diffuse into the inside of the reaction box, and fully react with carbon tetrachloride in the aeration reaction box 2.

[0045] The treated solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com