Flocculant feeding device

A technology of feeding device and flocculant is applied in the field of feeding device, which can solve the problems of poor thermal conductivity of powder, influence processing, poor sealing performance of the outlet, etc., and achieve the effect of ensuring long-term drying, simple and reliable structure, and good sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

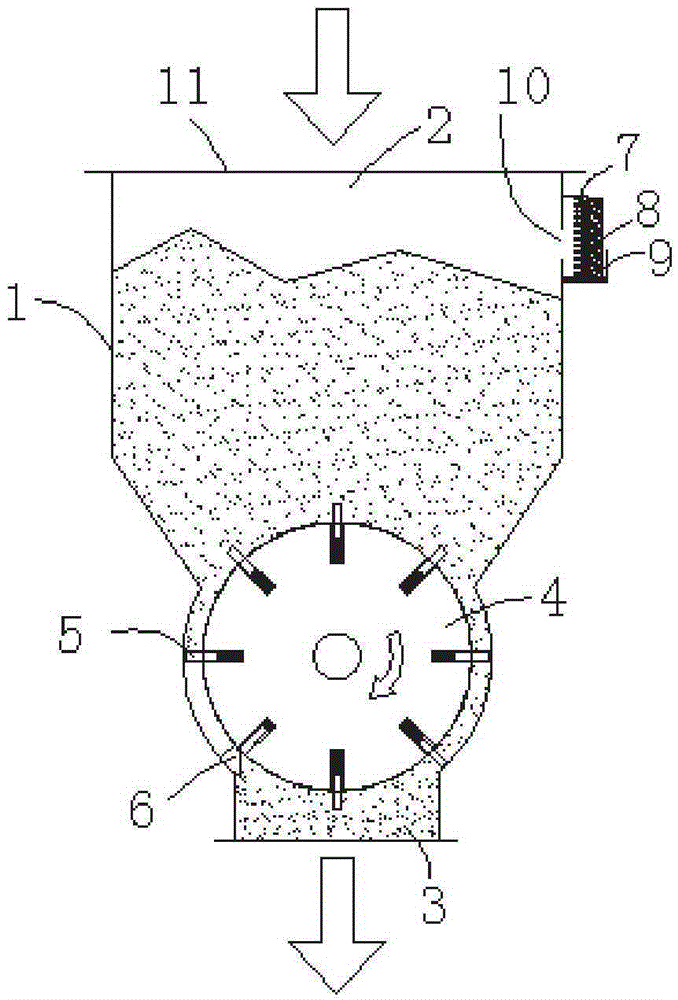

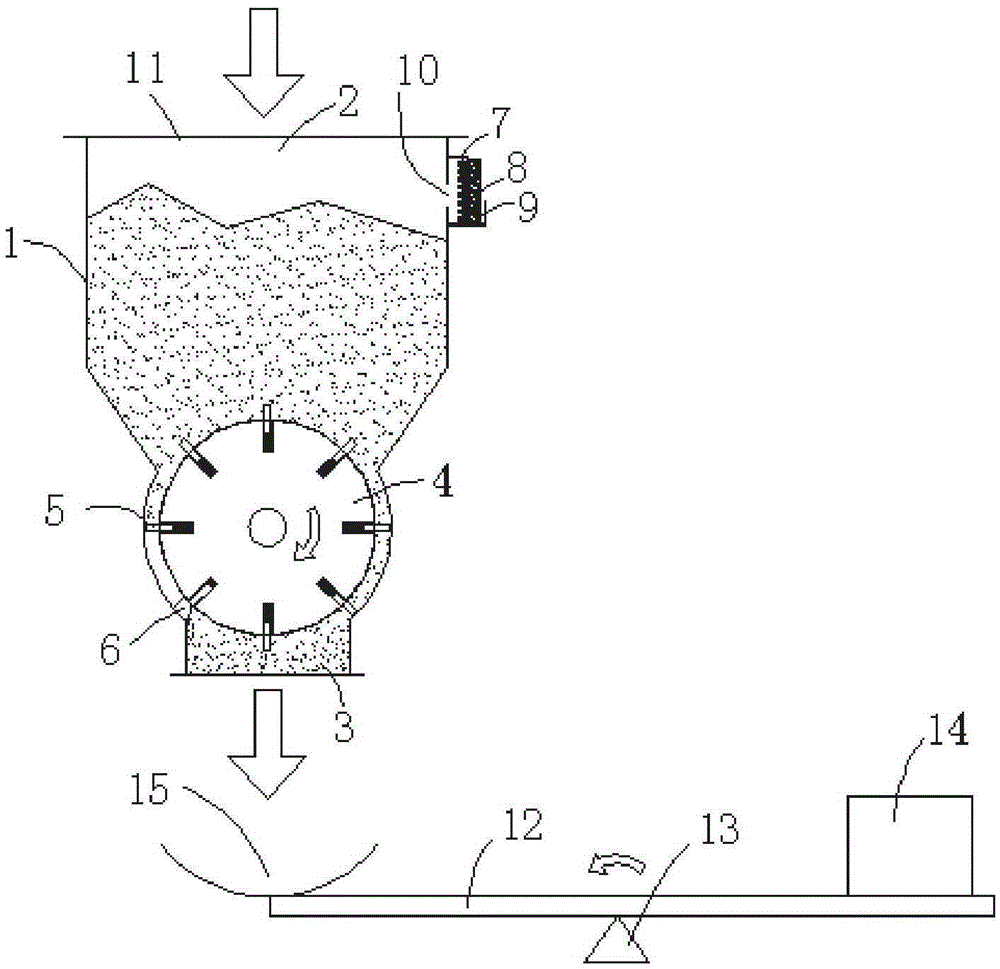

[0034] Such as figure 1 As shown, a flocculant feeding device disclosed in Example 1 of the present invention includes a silo 1, an impeller rotor, and a refrigeration dehumidification device. The top of the silo 1 is provided with a feeding port 2, and the bottom is provided with a discharge port. 3. A transparent plexiglass cover plate 11 is provided on the feeding port 2 . The impeller rotor is arranged in the silo 1 and is located near the discharge port 3 . When the impeller rotor is not rotating, it blocks the discharge port 3; when it rotates clockwise, the material is discharged with the rotation of the impeller rotor.

[0035] In Embodiment 1, the impeller rotor includes a rotor 4 and eight blades 5 evenly distributed on the outer circumference of the rotor 4 , and the blades 5 are connected to the rotor 4 through springs. A scraper 6 is arranged on the inner wall of the silo near the discharge port 3 , and when the rotor 4 rotates, the scraper 6 can contact the bla...

Embodiment 2

[0039] Such as figure 1 As shown, different from the structure of a flocculant feeding device disclosed in Example 1, the number of blades 5 on the rotor 4 in Example 2 is set to 16, and a Set up a weighing device to automatically tilt and feed when the preset weight is reached. The 16 elastic blades 5 can control the feeding more finely, combined with the weighing device at the bottom, the feeding amount can be controlled more precisely. Embodiment 2 is applicable to occasions requiring precise feeding. For other structures and working principles, refer to the introduction in Embodiment 1 above, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com