Flue gas concerted catalytic denitration and demercuration technology

A synergistic catalysis and flue gas technology, applied in heterogeneous catalyst chemical elements, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of increasing equipment costs, waste water pollution, secondary pollution and other problems, to achieve the effect of saving renovation costs and reducing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

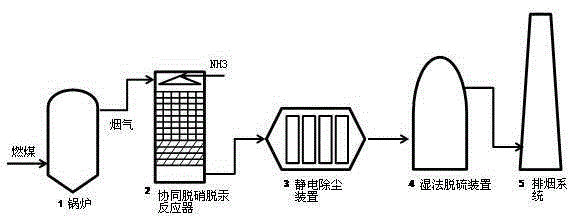

[0021] A flue gas synergistic catalytic denitrification and mercury removal process, which comprises the following steps:

[0022] (1) Spray the ammonia gas that has been fully mixed with air into the boiler flue gas through the nozzle of the ammonia injection grid to make it fully mixed. At 350°C, the flow velocity in the catalyst hole is 7m / s, and the space velocity is 30001 / h. The upper half of the honeycomb Ce-Cu-V-W-TiO at a surface velocity of 8m / h 2 Under the action of composite catalyst, the NO in the flue gas x converted to N 2 .

[0023] (2) Pass the flue gas treated in step (1) through honeycomb Ce-Cu-V-W-TiO at 350°C 2 Under the action of the composite catalyst, a small amount of O 2 and HCl with Hg 0 Catalytic oxidation to generate HgCl 2 .

[0024] (3) The gas treated in step (2) enters the operation unit of the wet oxidation desulfurization tower, the gaseous divalent mercury is easily soluble in water and is captured and removed by the wet scrubbing syst...

Embodiment 2

[0027] A flue gas synergistic catalytic denitrification and mercury removal process, which comprises the following steps:

[0028] (1) Spray the ammonia gas that has been fully mixed with air into the boiler flue gas through the nozzle of the ammonia injection grid to make it fully mixed. At 380°C, the flow velocity in the catalyst hole is 7m / s, and the space velocity is 36001 / h. The upper half of the honeycomb Ce-Mn-V-W-TiO at a surface velocity of 9m / h 2 Under the action of composite catalyst, the NO in the flue gas x converted to N 2 .

[0029] (2) Pass the flue gas treated in step (1) into, at 380 o C via honeycomb Ce-Mn-V-W-TiO 2 Under the action of the composite catalyst, a small amount of O 2 and HCl with Hg 0 Catalytic oxidation to generate HgCl 2 .

[0030] (3) The gas treated in step (2) enters the operation unit of the wet oxidation desulfurization tower, the gaseous divalent mercury is easily soluble in water and is captured and removed by the wet scrubbing...

Embodiment 3

[0033] A flue gas synergistic catalytic denitrification and mercury removal process, which comprises the following steps:

[0034] (1) Spray the ammonia gas fully mixed with the air into the boiler flue gas through the nozzle of the ammonia injection grid to make it fully mixed. At 400°C, the flow velocity in the catalyst hole is 6m / s, and the space velocity is 40001 / h. The upper half of the honeycomb Ce-Mn-V-W-TiO at a surface velocity of 8m / h 2 Under the action of composite catalyst, the NO in the flue gas x converted to N 2 .

[0035] (2) Pass the treated flue gas in step (1), at 400 oC via honeycomb Ce-Mn-V-W-TiO 2 Under the action of the composite catalyst, a small amount of O 2 and HCl with Hg 0 Catalytic oxidation to generate HgCl 2 .

[0036] (3) The gas treated in step (2) enters the operation unit of the wet oxidation desulfurization tower, the gaseous divalent mercury is easily soluble in water and is captured and removed by the wet scrubbing system, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com