Capacitor module and manufacturing method thereof

A technology for capacitors and shells, which is applied in the field of capacitor modules and its manufacturing, which can solve problems such as hindering weight reduction, achieve the effects of reducing load, maintaining capacitor performance, and preventing deterioration of sealing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

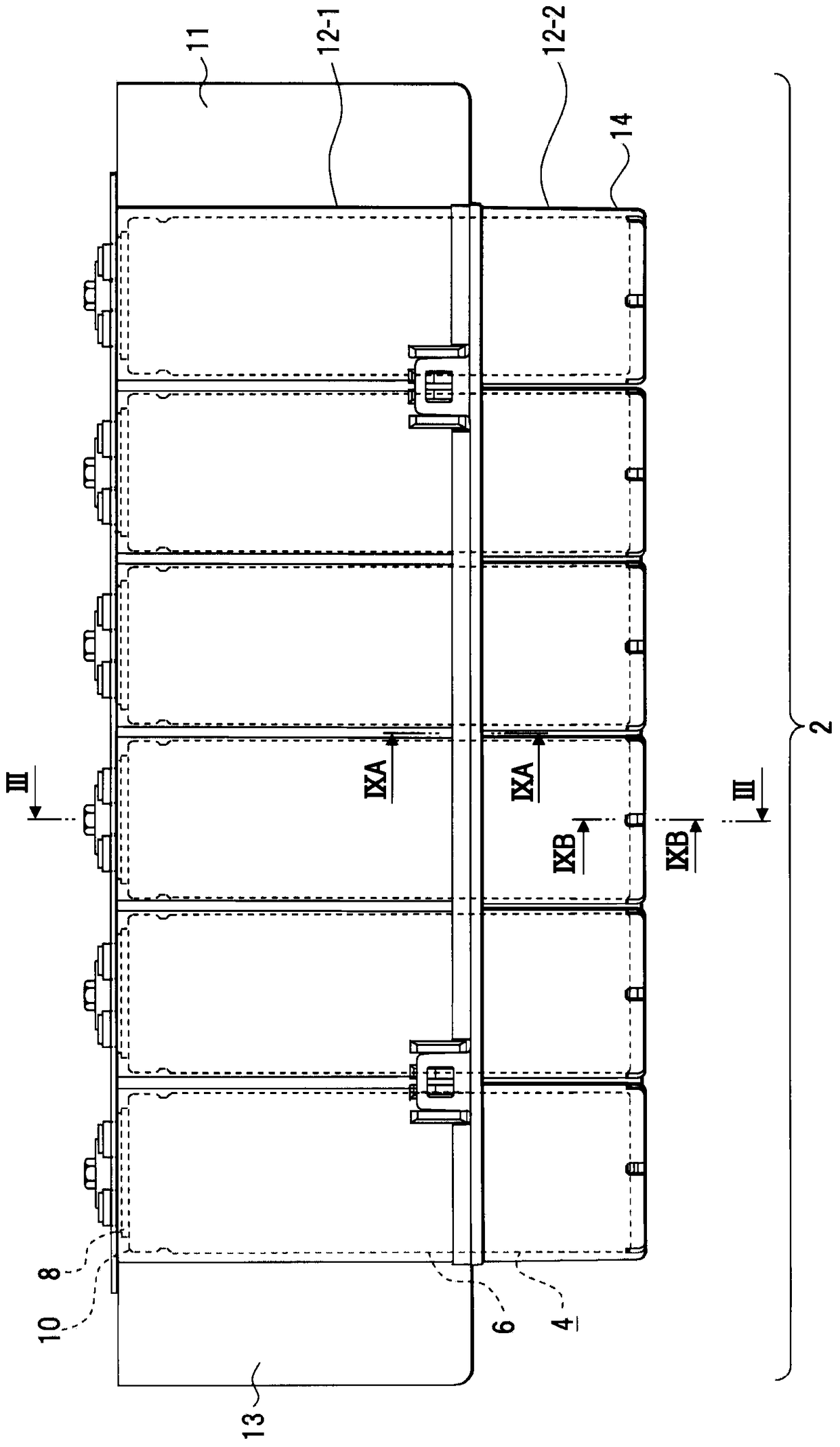

[0047] figure 1 A configuration example of the capacitor module of the first embodiment is shown. The capacitor module 2 includes a plurality of capacitors 4 . In this embodiment, six capacitors 4 are used, but the number may be six or less or six or more. For each capacitor 4, for example, an electric double layer capacitor or an electrolytic capacitor is used.

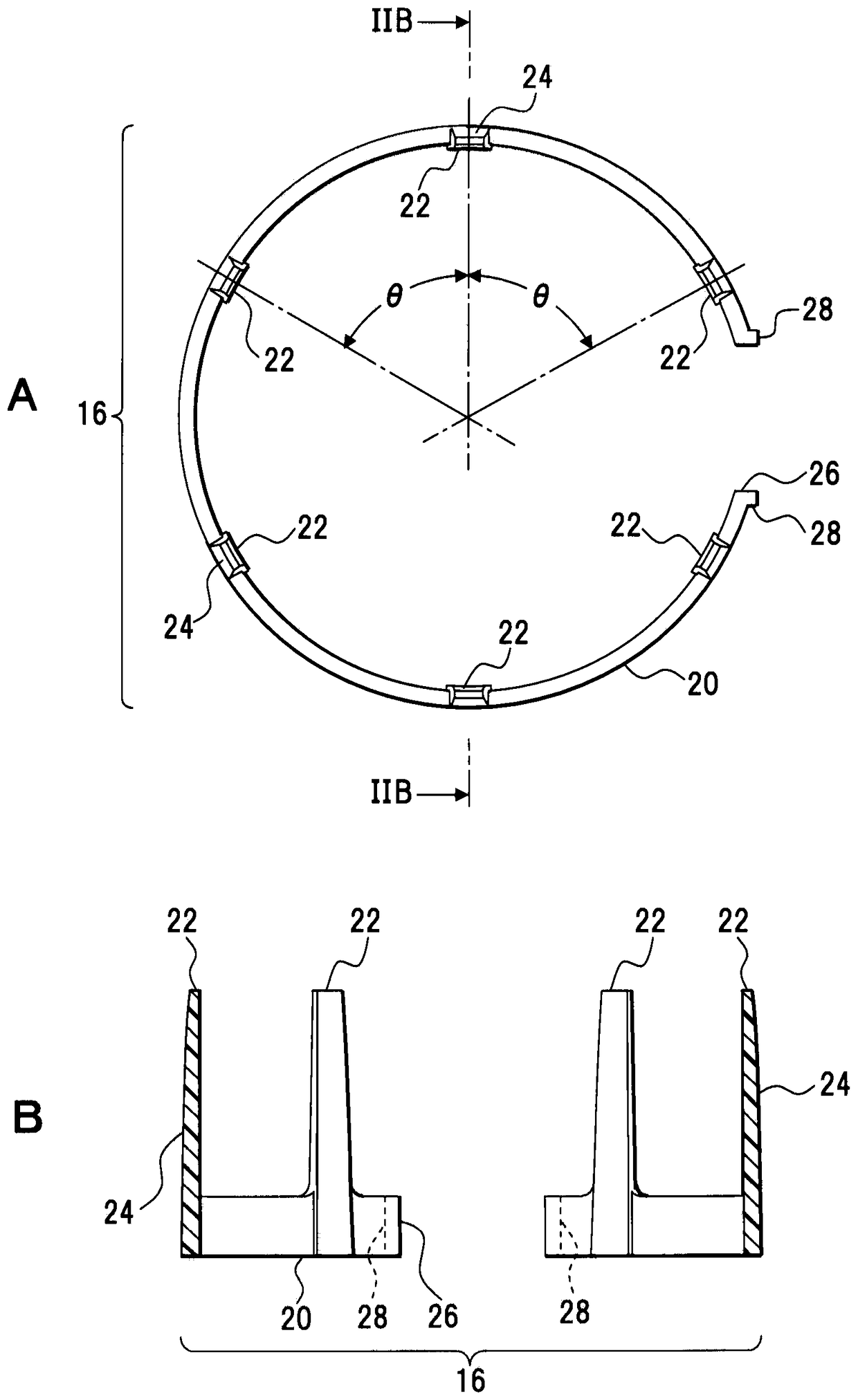

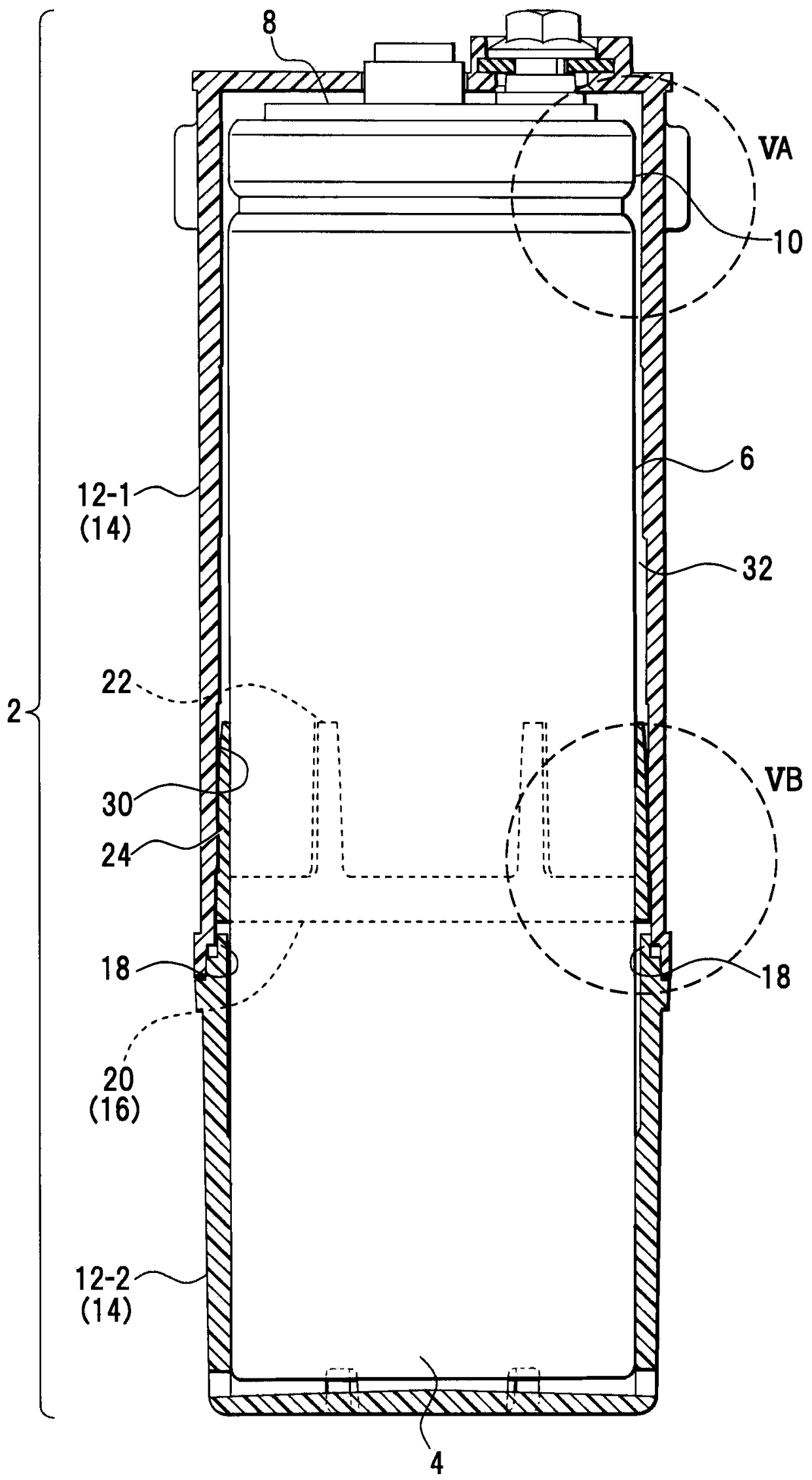

[0048]Each capacitor 4 has a case 6 in which a capacitor element is accommodated. The housing 6 is molded from aluminum, for example. The casing 6 is sealed by a sealing plate 8 . The sealing plate 8 is formed of an insulating plate such as an insulating synthetic resin, and an anode terminal, a cathode terminal, and an auxiliary terminal are formed as external terminals on the sealing plate 8 . The anode terminal, the cathode terminal, and the auxiliary terminal are integrally attached to the sealing plate 8 by insert molding when the sealing plate 8 is formed. The anode terminal is connected to the anode of t...

no. 2 Embodiment approach

[0084] Next, a configuration example of the main case 12-1 and the bottom case 12-2 that accommodate a plurality of capacitors will be described. When the capacitor module 2 is installed in, for example, a motor vehicle, it is installed outside the cabin and exposed to the outside air. Therefore, there is a possibility that water droplets may adhere to or accumulate on the capacitor module 2 due to dew condensation or the like. Even if water droplets adhere to the case member, the water droplets do not degrade the capacitor 4 . However, the adhered water droplets may corrode the resin constituting the case member.

[0085] In addition, in the capacitor module 2 of the present disclosure, for example, since the housing portion 14 is not filled with resin or the like, there is a possibility that water droplets generated by dew condensation etc. adhering to the outer surface of the capacitor 4 may intrude into the main case 12-1. And bottom shell 12-2 and accumulate. Therefore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com