Ultraviolet curing coating and preparation method thereof

A technology for curing coatings and ultraviolet light, applied in polyester coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., which can solve the problems of low initiation efficiency, little production, and insufficient film curing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

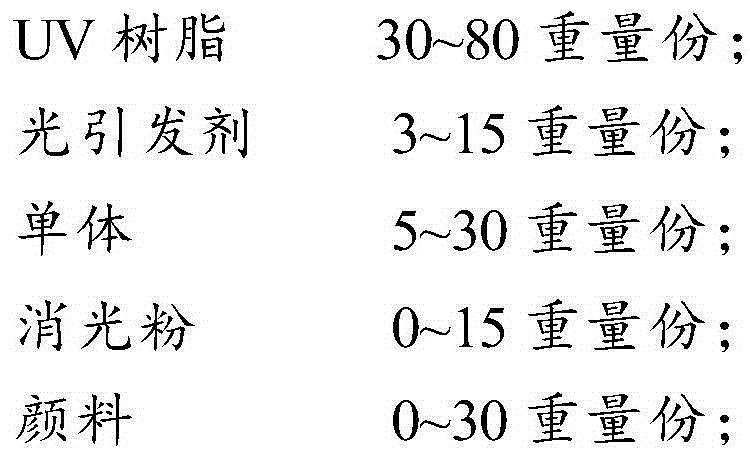

[0044] The present invention also provides a preparation method of the above-mentioned UV-curable coating, comprising: 30-80 parts by weight of UV resin, 3-15 parts by weight of photoinitiator, 5-30 parts by weight of monomer, 0-15 parts by weight The matting powder in parts by weight is mixed with 0-30 parts by weight of pigment to obtain a UV-curable coating; the UV resin is selected from bisphenol A epoxy acrylate resin, polyester acrylic resin, polyurethane acrylic resin and silicone resin. One or more; the photoinitiator is selected from one of aromatic ketone photoinitiators, α-hydroxy ketone derivatives, benzyl, acyl phosphorus oxide photoinitiators and acyl phosphorus oxide derivatives One or more; the monomer is an acrylic monomer and / or a modified acrylic monomer.

[0045] According to the present invention, it is preferable to add one of 0.5 to 5 parts by weight of dispersant, 0.2 to 0.5 parts by weight of defoamer, 0.1 to 1 part by weight of leveling agent and 0.1 ...

Embodiment 1

[0051] The contents of each component of the UV-curable coating are shown in Table 1.

[0052] The content of each component of UV-curable coating in table 1 embodiment 1

[0053]

[0054] The 100% UV resin is Cytec UV resin, the dispersant is BYK-103, the defoamer is BYK-055, the leveling agent is BYK358, the anti-settling agent is Degussa brand R-972, and the photoinitiator is Ciba The brand is 1173, the matting agent is Degussa brand OK-500, the titanium dioxide is titanium dioxide DuPont brand R-760, and the monomer is polyacrylic acid monomer of Cytec.

[0055] Stir 100% UV resin, some monomers, defoamer, dispersant and photoinitiator evenly, then add matting powder and titanium dioxide to fully disperse, finally add leveling agent and anti-settling agent to disperse evenly, add the remaining mono The viscosity of the monomer is adjusted to obtain a UV-curable coating, and the mass ratio of some monomers to the remaining monomers is 20:1.

[0056] Coat the UV-curable...

Embodiment 2

[0062] The content of each component of the UV-curable coating is shown in Table 3, and the others are the same as in Example 1.

[0063] The content of each component of UV-curable coating in the embodiment 2 of table 3

[0064]

[0065] The performance of the paint film in Example 2 was detected, and the results obtained are shown in Table 4.

[0066] Paint film performance testing result in table 4 embodiment 2

[0067]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com