TiO2-doped infrared-transmitting aluminate glass ceramic and preparation method thereof

A glass ceramic and aluminate technology, which is applied in the field of TiO2 doped infrared transparent aluminate glass ceramic and its preparation, can solve the problems of poor chemical stability, limited preparation technology and high production cost, and achieves low raw material cost, environmental protection and safety. Good properties and improved glass hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

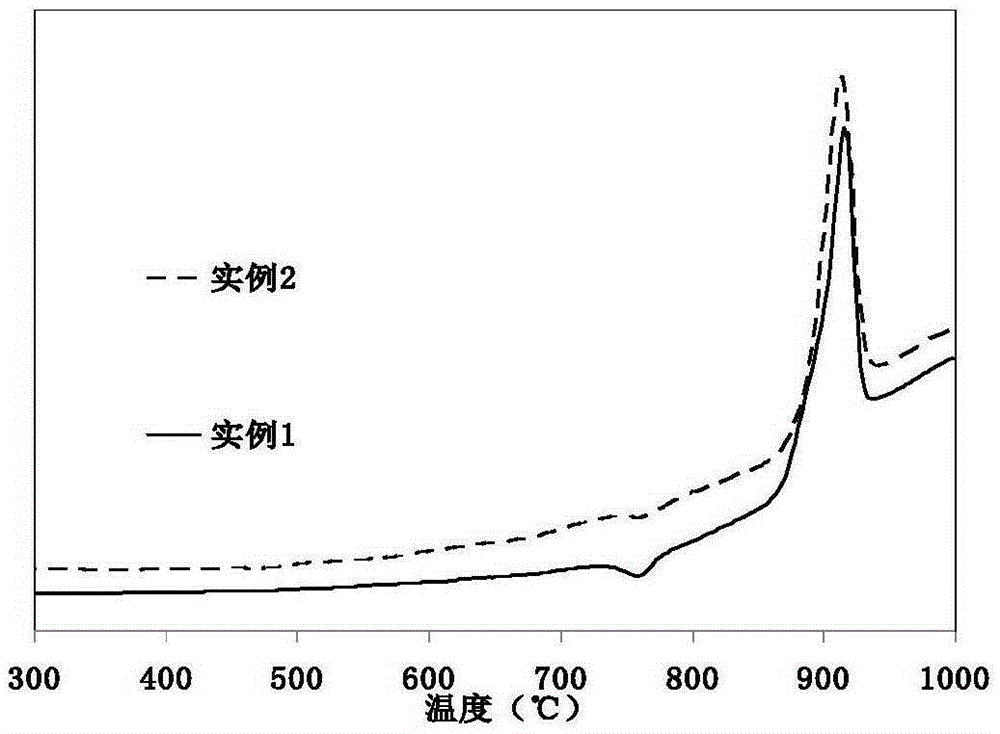

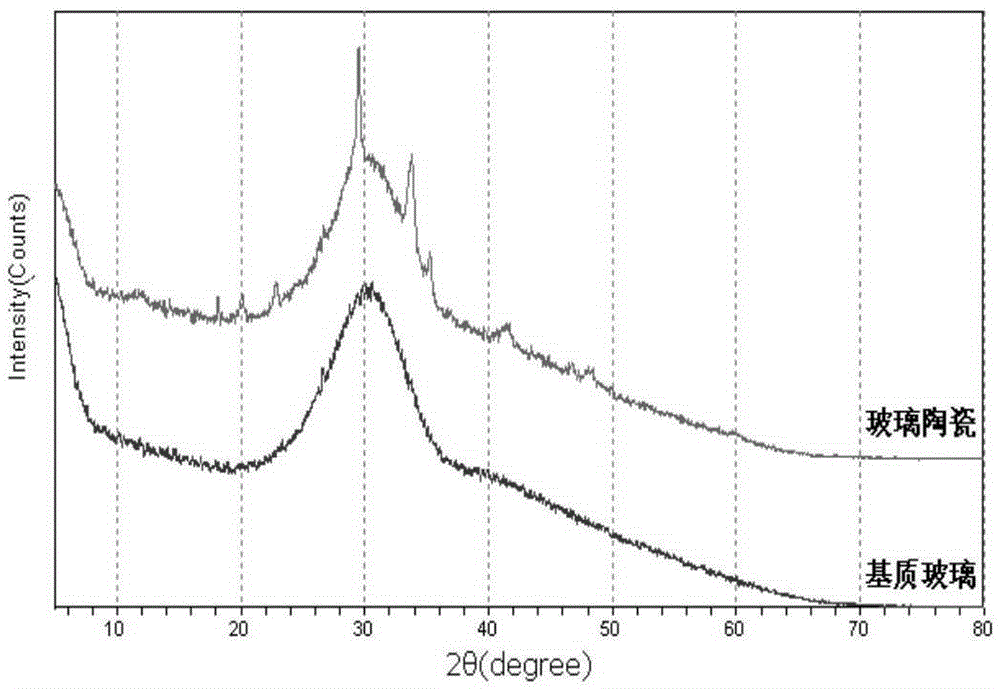

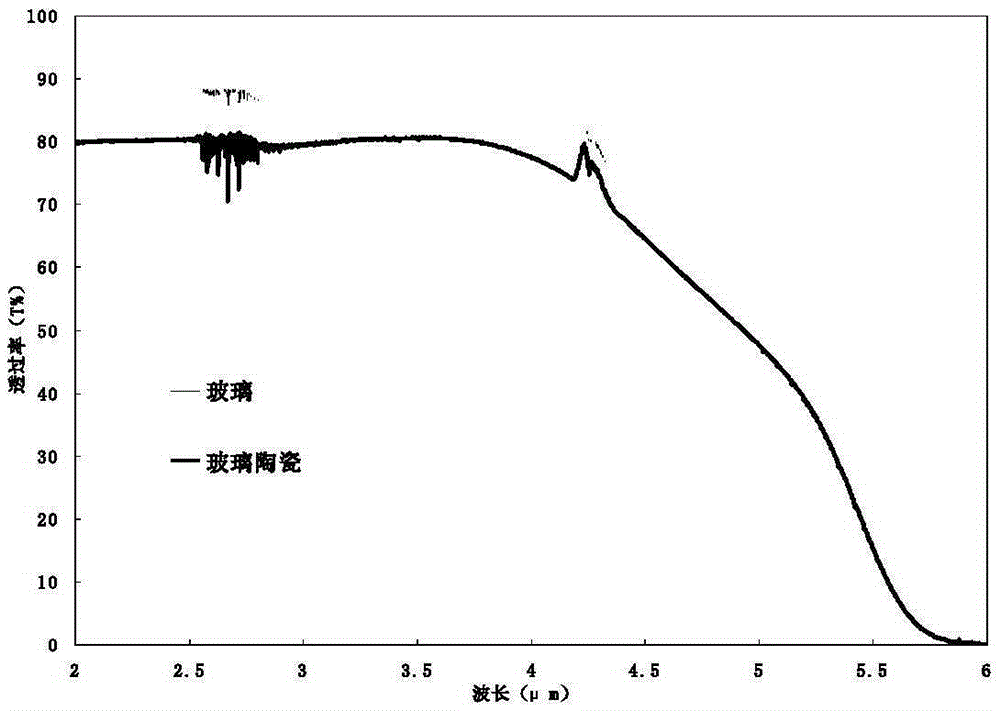

Embodiment 1

[0027] Weigh and mix to make aluminate glass batch 10kg (wt%) according to the following composition ratio: 40% Al 2 o 3 , 36% CaO, 7% BaO, 4% MgO, 8% Na 2 O, 5%TiO 2 , the batch material is melted in a silicon-molybdenum rod electric furnace with a platinum-rhodium alloy crucible, the melting temperature is 1450 ° C, and the melting time is 16 hours. After melting, the molten glass is poured into a preheated cast iron mold and cooled to obtain TiO 2 Doped infrared-transmitting aluminate glass clinker.

[0028] Put the clinker crushed into 5-10mm particles into a platinum-rhodium alloy crucible and melt in a vacuum induction melting furnace with a melting temperature of 1500°C and a maximum vacuum of 1.0×10 -3 Pa. After being completely melted and clarified for 1 to 2 hours, pour the molten glass into a preheated cast iron mold, quickly transfer it to an electric furnace for annealing after molding, and obtain colorless and transparent TiO after cooling. 2 Doped infrared-...

Embodiment 2

[0031] Weigh and mix to make aluminate glass batch 10kg (wt%) according to the following composition ratio: 45% Al 2 o 3, 30% CaO, 6% BaO, 6% MgO, 10% Na 2 O, 3%TiO 2 , the batch material is melted in a silicon-molybdenum rod electric furnace with a platinum-rhodium alloy crucible, the melting temperature is 1550 ° C, and the melting time is 12 hours. After melting, the molten glass is poured into a preheated cast iron mold and cooled to obtain TiO 2 Doped infrared-transmitting aluminate glass clinker.

[0032] Put the clinker crushed into 5-10mm particles into a platinum-rhodium alloy crucible and melt in a vacuum induction melting furnace with a melting temperature of 1600°C and a maximum vacuum of 1.0×10 -3 Pa. After being completely melted and clarified for 1 to 2 hours, pour the molten glass into a preheated cast iron mold, quickly transfer it to an electric furnace for annealing after molding, and obtain TiO after cooling. 2 Doped infrared-transmitting aluminate gla...

Embodiment 3

[0035] Weigh and mix according to the following composition ratio to make aluminate glass batch 10kg (wt%): 35% Al 2 o 3 , 40% CaO, 8% BaO, 2% MgO, 6% Na 2 O, 3%K 2 O, 6%TiO 2 , the batch material is melted in a silicon-molybdenum rod electric furnace with a platinum-rhodium alloy crucible, the melting temperature is 1550 ° C, and the melting time is 8 hours. After melting, the molten glass is poured into a preheated cast iron mold and cooled to obtain TiO 2 Doped infrared-transmitting aluminate glass clinker.

[0036] Put the clinker crushed into 5-10mm particles into a platinum-rhodium alloy crucible and melt it in a vacuum induction melting furnace with a melting temperature of 1550°C and a maximum vacuum degree of 1.0×10 -2 Pa. After being completely melted and clarified for 1 to 2 hours, pour the molten glass into a preheated cast iron mold, quickly transfer it to an electric furnace for annealing after molding, and obtain TiO after cooling. 2 Doped infrared-transmi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com