Chalcogenide glass preparation method and preparation device

A technology of chalcogenide glass and preparation equipment, which is applied in the field of chalcogenide glass preparation, can solve the problems of many internal stripe defects in chalcogenide glass, the small size of the prepared sample, and the difficulty of chalcogenide glass, so as to improve the practical level and improve the transparency of the chalcogenide glass. Good performance and optical uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

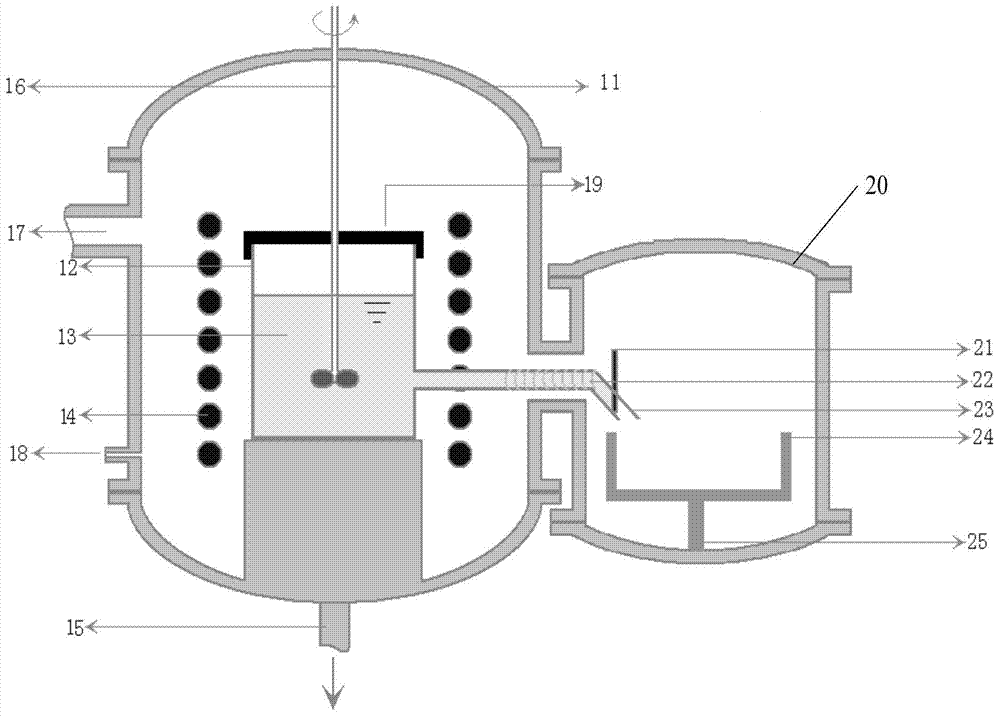

[0029] The embodiment of the present invention also proposes a method for preparing chalcogenide glass suitable for large size and high uniformity, preferably using the above-mentioned chalcogenide glass preparation device. The method includes the following three steps: vacuum low-temperature purification, under vacuum conditions, at the a temperature T 1 Purify the glass raw materials to remove impurities; vacuum high temperature melting, under vacuum conditions, at the second temperature T 2 The glass raw material is melted to obtain molten glass in a molten state; the leakage is formed, and the molten glass is leaked and shaped to obtain a finished glass; the vacuum condition is that the pressure is less than 1.0×10 -2 Pa. Preferably, the purity of the glass raw material is 5N grade. The selection of the glass raw material should meet the requirement that the final chalcogenide glass is composed of the following substances: one or both of Ge element and As element, and it...

example 1

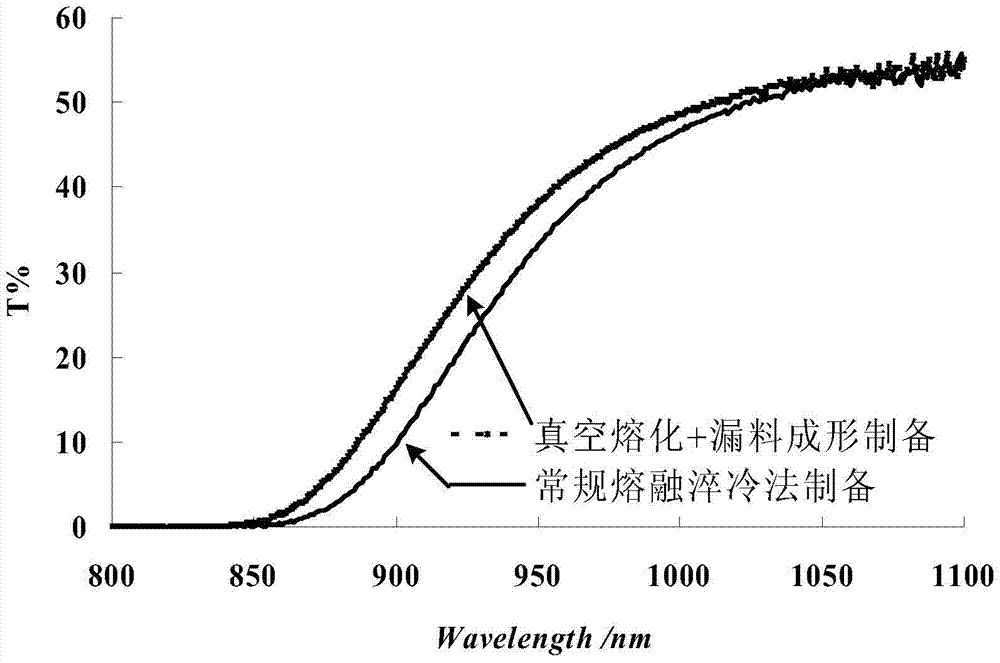

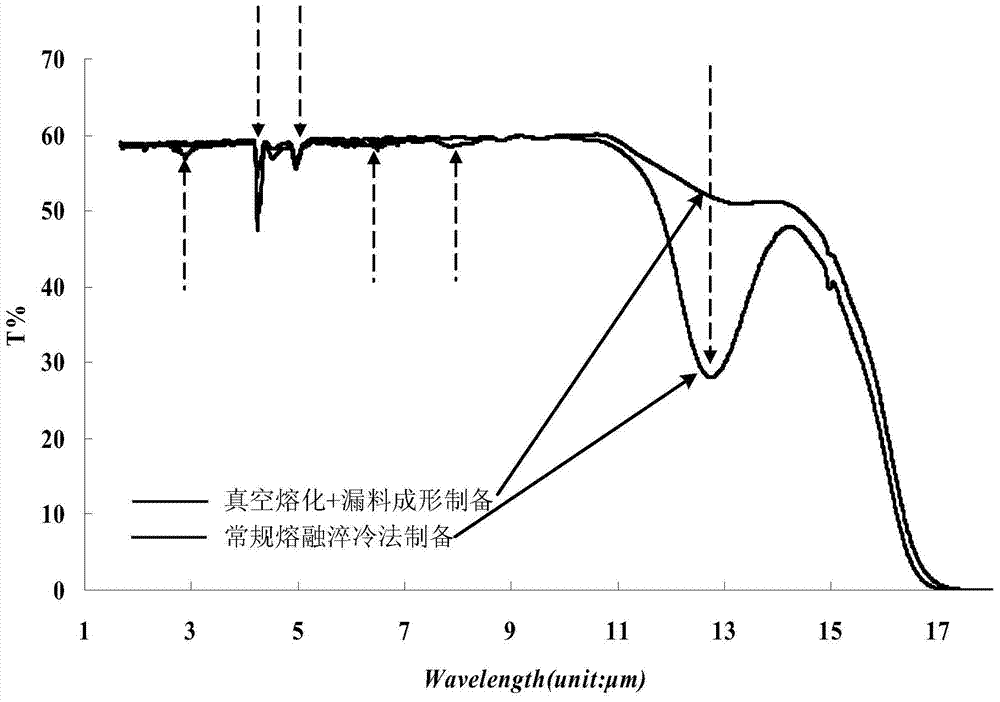

[0035] According to germanium, selenium, and antimony elemental substances, the chalcogenide glass raw materials are weighed in the precise ratio of 28mol%, 60mol% and 12mol% respectively to make a mixture 1, and 200ppm of oxygen scavenger aluminum is introduced into the above mixture 1, and the mixture 1 is filled with Put into the quartz crucible 12 of vacuum melting furnace, carry out vacuumizing by vacuum melting furnace 17 positions, to 5 * 10 -3 Around Pa, the coil 14 starts to heat up, and the temperature rises to T within 0.5h 1 = 350°C purification for 2h. After the purification is completed, the temperature is raised rapidly: the temperature is raised to T at a speed of 10°C / min 2 =950°C, and kept at this temperature for 4h. At the beginning of heat preservation, introduce a quartz stirrer into the molten glass to homogenize the molten glass. The stirring speed is 10rpm / min. The stirring process system is: stirring for 10min, then standing for 20min, repeating 3 ti...

example 2

[0041] use attached figure 1 The shown device purifies molten Ge 20 Se 65 Sb 15 Glass raw material, take by weighing 5000g raw material and 100ppm of oxygen scavenger aluminum with the accurate proportioning ratio of 20mol%, 65mol% and 15mol% respectively according to germanium, selenium, antimony simple substance and use as mixture 1, put mixture 1 into the vacuum melting furnace In the quartz crucible 12, vacuumize to 6×10 through the vacuum melting furnace 17 positions - 4 About Pa, heat the coil 4, and raise the temperature to T within half an hour 1 = 300°C purification for 2h. Rapid temperature rise after purification: heat up to T at a rate of 8°C / min 2 =930°C, and kept at this temperature for 5h. During the heat preservation process, the molten glass is homogenized by a quartz mechanical stirring device, the stirring speed is 10rpm / min, and the stirring process system is: stirring for 20 minutes, then standing for 20 minutes, and repeating twice. After the heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com