Preparation method of nano iron oxide-multilayered graphene composite material

A technology of nano-iron oxide and multi-layer graphene, which is applied in the field of materials, can solve the problems of no high activity, etc., and achieve the effect of being convenient for industrial production, conducive to industrial preparation, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

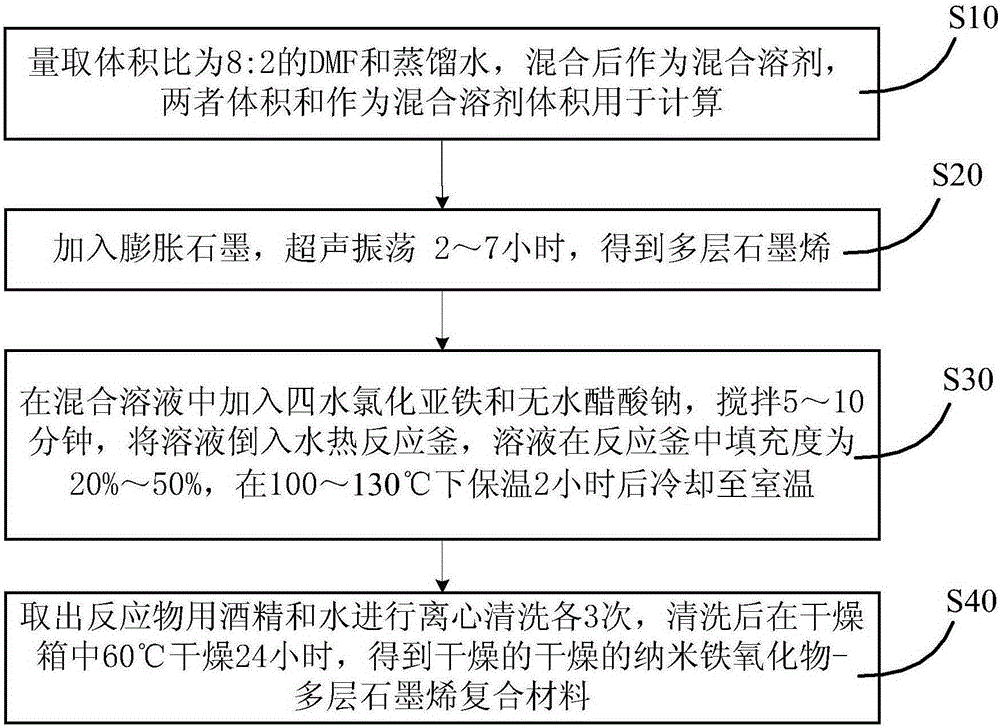

[0030] see figure 1 , which is a flow chart of the steps of the preparation method of the nano-iron oxide-multilayer graphene composite material of the embodiment of the present invention, which includes the following steps:

[0031] S10, measure DMF (dimethylformamide) and distilled water with a volume ratio of 8:2, mix them as a mixed solvent, and the volume of the two and the volume of the mixed solvent are used for calculation;

[0032] S20, adding expanded graphite and ultrasonically vibrating for 2 to 7 hours to obtain a mixed solvent of multilayer graphene;

[0033] Wherein the expanded graphite is 1.3mg / mL-2.5mg / mL relative to the mixed solvent, the oxygen content on the surface of the multilayer graphene is less than 3%, and the number of layers is less than 100.

[0034] S30, add ferrous chloride tetrahydrate and anhydrous sodium acetate to the multi-layer graphene mixed solvent, stir for 3 to 6 minutes, pour the solution into a hydrothermal reaction kettle, and kee...

Embodiment 1

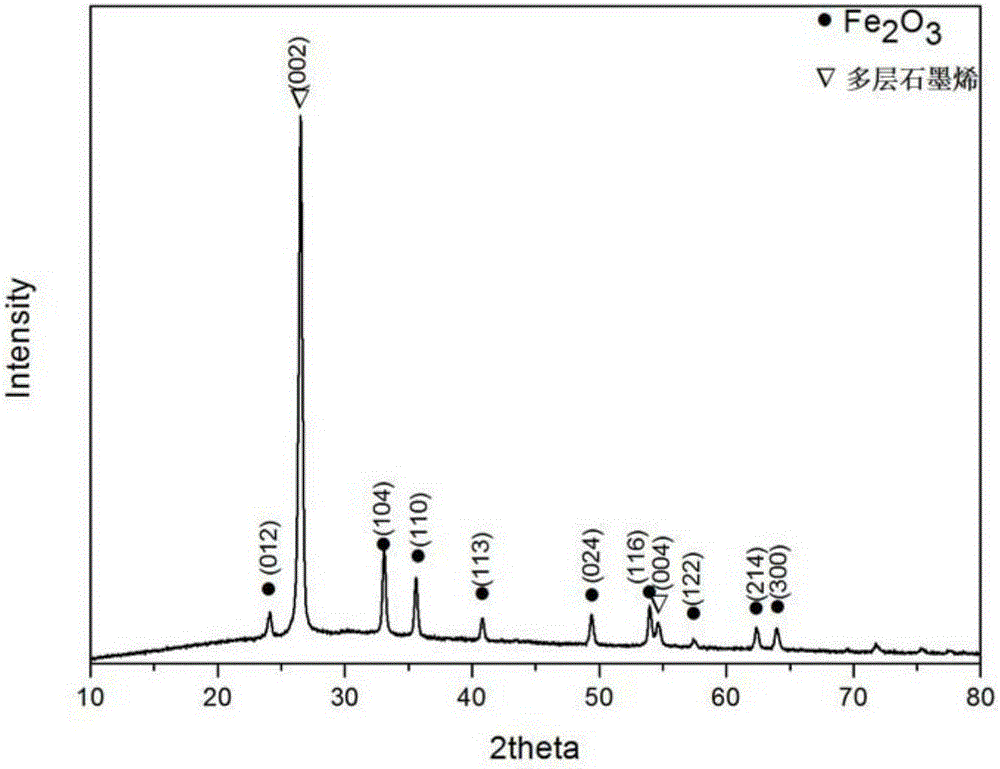

[0038] Mix 8ml of DMF and 2ml of distilled water as a mixed solvent, add 15mg of expanded graphite, and ultrasonically vibrate for 2 hours to obtain the multilayer graphene required by the present invention. Add 100mgFecl to the mixed solution 2 4H 2 O was stirred for 5 minutes; the solution was poured into the hydrothermal reactor, so that the filling degree of the solution in the hydrothermal reactor was 30%. Insulate at 120°C for 2 hours and then cool to room temperature; take out the reactants and wash them with alcohol and water for 3 times, and finally dry at 60°C in a drying oven for 24 hours to obtain Fe 2 o 3 - Multilayer graphene composites. see figure 2 and Figure 5 , which are Fe 2 o 3 - The XRD pattern of the multilayer graphene composite material and its scanning electron microscope image, it can be seen from the figure that the reaction obtained is Fe 2 o 3 Particles, whose size is about 100nm. The size uniformity is poor, the distribution is relativ...

Embodiment 2

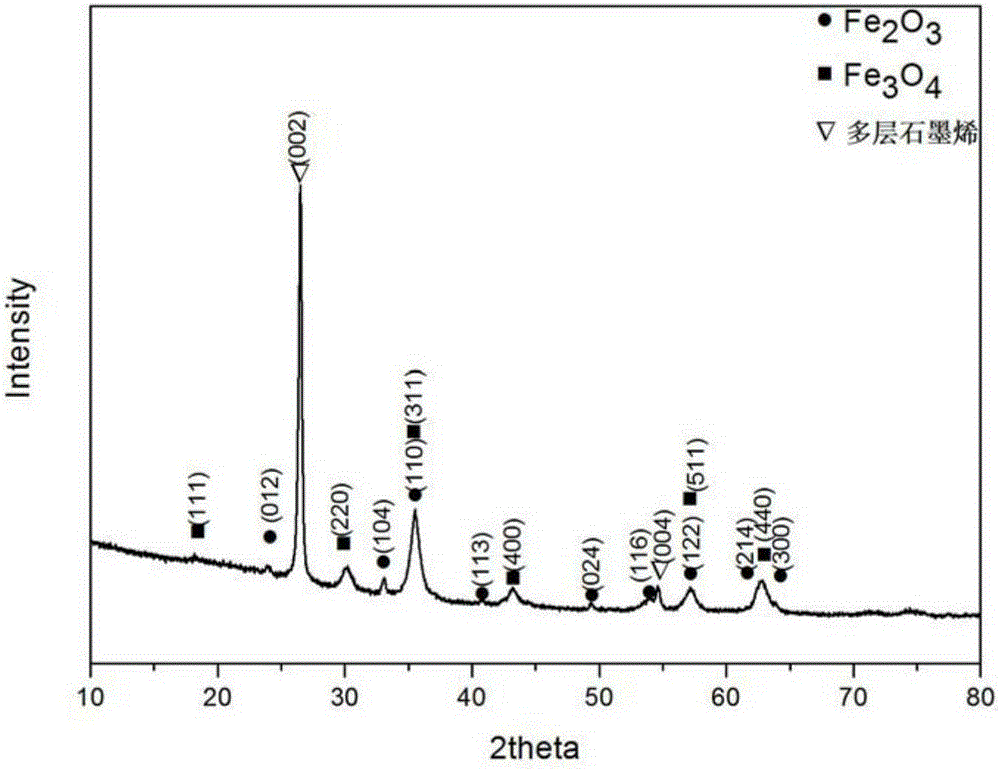

[0040] Mix 8ml of DMF and 2ml of distilled water as a mixed solvent, add 15mg of expanded graphite, and ultrasonically vibrate for 2 hours to obtain the multilayer graphene required by the present invention. Add 100mgFecl to the mixed solution 2 4H 2 O and 200 mg of anhydrous sodium acetate were stirred for 5 minutes; the solution was poured into the hydrothermal reaction kettle, so that the filling degree of the solution in the hydrothermal reaction kettle was 30%. Keep warm at 120°C for 2 hours and then cool to room temperature; take out the reactants and wash them with alcohol and water for 3 times, and finally dry them in a drying oven at 60°C for 24 hours to obtain nano-Fe 2 o 3 +Fe 3 o 4 - Multilayer graphene composites. see image 3 , which is the nano-Fe of this example 2 o 3 +Fe 3 o 4 - XRD patterns of multilayer graphene composites, see Figure 6 Among A and B, it is respectively the nanometer Fe of the present embodiment 2 o 3 +Fe 3 o 4 - Low- and hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com