Magnetic fingerprint revealing powder and preparation method and application thereof

A magnetic powder and fingerprint technology, applied in applications, medical science, sensors, etc., can solve problems such as endangering the health of operators, harsh conditions for powder use, and lack of high adaptability, and achieves the promotion of industrial production and high temperature stability. , the effect of stable nature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In this embodiment, the chemical formula of the magnetic powder showing fingerprints is Fe 50 (BN) 50 .

[0039] The preparation method of above-mentioned fingerprint revealing magnetic powder is as follows:

[0040] (1) prepare commercially available Fe powder and BN powder;

[0041] (2) The purity of the Fe powder is 99.5%, the particle size is 35 μm, the purity of the BN powder is 99.5%, the particle size is 10 μm, and the ingredients are made according to the composition atomic percentage;

[0042] (3) Place the raw materials weighed in step (2) in a ball mill, the ball-to-material ratio is 10:1, the ball milling process parameters are rotating speed: 200 rpm, time: 90 minutes and 400 mesh size sieve;

[0043] (4) Put the magnetic powder mixture obtained in step (3) in an oven for 60 minutes.

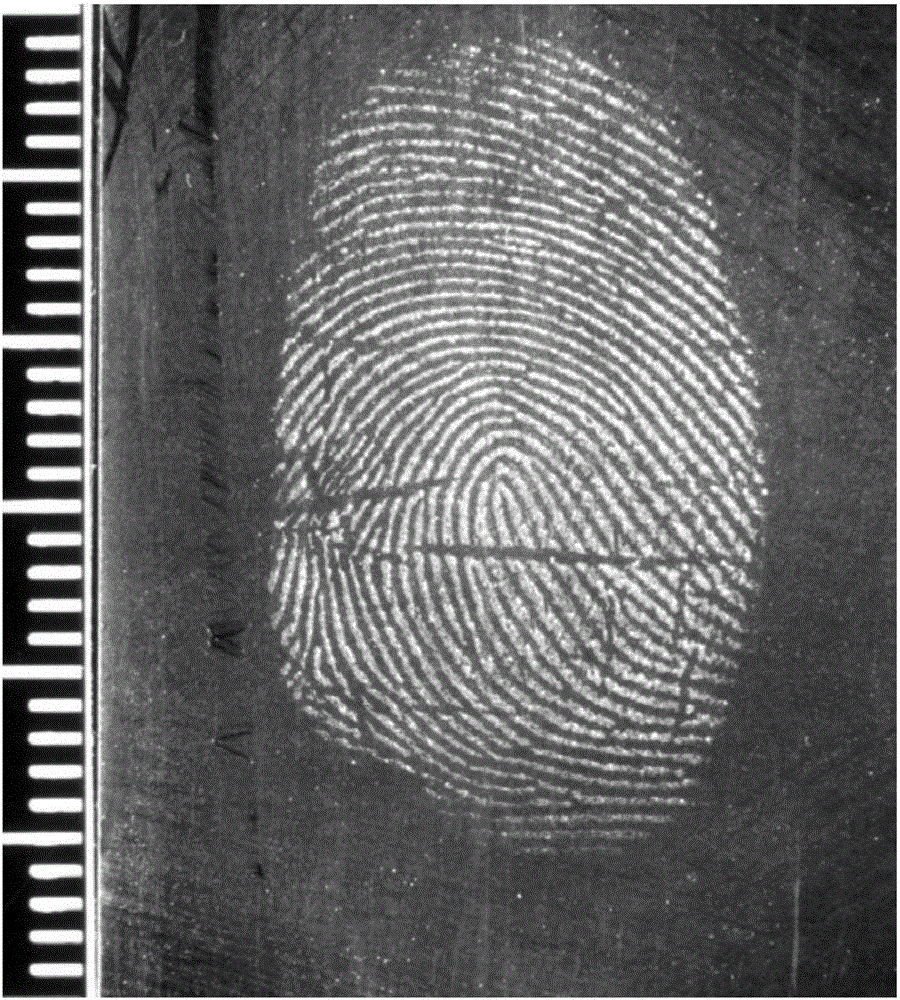

[0044] (5) Detect the effect of fingerprint display on the above-mentioned obtained, print the fingerprint on the glass sheet with your fingers, and absorb Fe with the tip ...

Embodiment 2

[0047] In this embodiment, the chemical formula of the magnetic powder showing fingerprints is Fe 50 (BN) 50 .

[0048] The preparation method of above-mentioned fingerprint revealing magnetic powder is as follows:

[0049] (1) prepare commercially available Fe powder and BN powder;

[0050] (2) The purity of the Fe powder is 99.5%, the particle size is 35 μm, the purity of the BN powder is 99.5%, the particle size is 10 μm, and the ingredients are made according to the composition atomic percentage;

[0051] (3) Place the raw materials weighed in step (2) in a ball mill, the ball-to-material ratio is 10:1, the ball milling process parameters are rotating speed: 300 rpm, time: 60 minutes and 400 mesh size sieve;

[0052] (4) Put the magnetic powder mixture obtained in step (3) in an oven for 60 minutes.

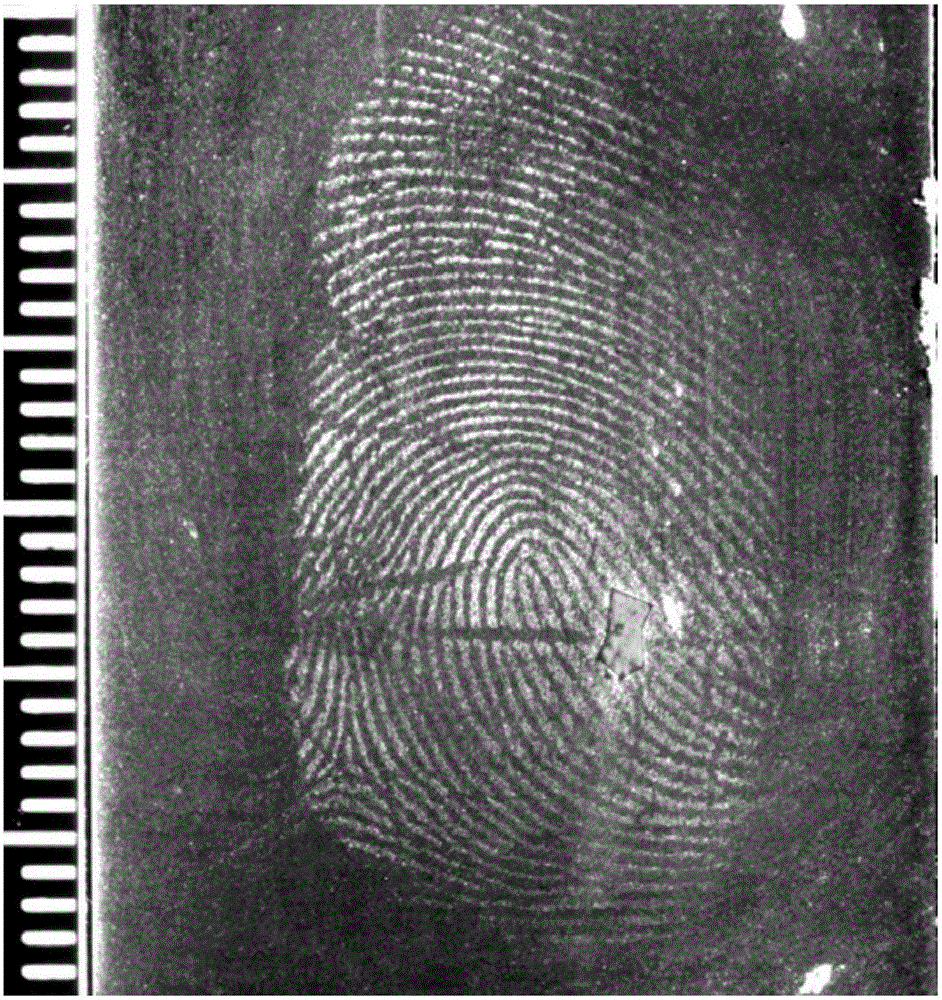

[0053] (5) To detect the effect of fingerprints produced above, print the fingerprints on the glass sheet with your fingers, then immerse the glass sheet in water for 30 ...

Embodiment 3

[0056] In this embodiment, the chemical formula of the fingerprint revealing magnetic powder is Co 66.7 (BN) 33.3 .

[0057] The preparation method of above-mentioned fingerprint revealing magnetic powder is as follows:

[0058] (1) prepare commercially available Co powder and BN powder;

[0059] (2) The purity of the Co powder is 99.5%, the particle size is 23 μm, the purity of the BN powder is 99.5%, the particle size is 10 μm, and the batching is carried out according to the composition atomic percentage;

[0060] (3) Place the raw materials weighed in step (2) in a ball mill, the ball-to-material ratio is 10:1, the ball milling process parameters are rotating speed: 300 rpm, time: 60 minutes and 600 mesh size sieve;

[0061] (4) Put the magnetic powder mixture obtained in step (3) in an oven for 60 minutes.

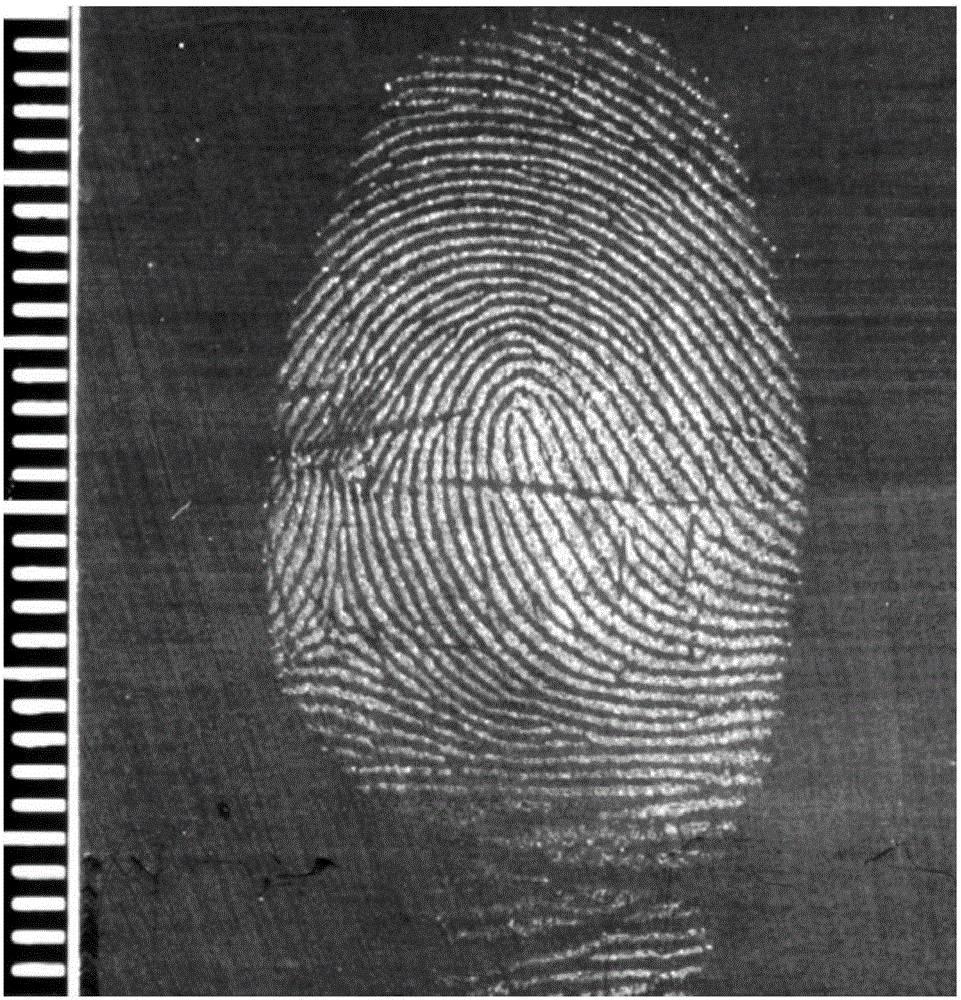

[0062] (5) Detect the fingerprint display effect of the above-mentioned obtained, print the fingerprint on the desktop surface with your fingers, and absorb Co wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com