Method for measuring trace amount of inorganic impurities in boric acid

A determination method and boric acid technology, applied in the field of analytical chemistry, can solve the problems of easy introduction of other impurities, cumbersome processing, and unfavorable boric acid sample analysis, and achieve the effect of improving pretreatment speed, simple operation steps, and fast and efficient determination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

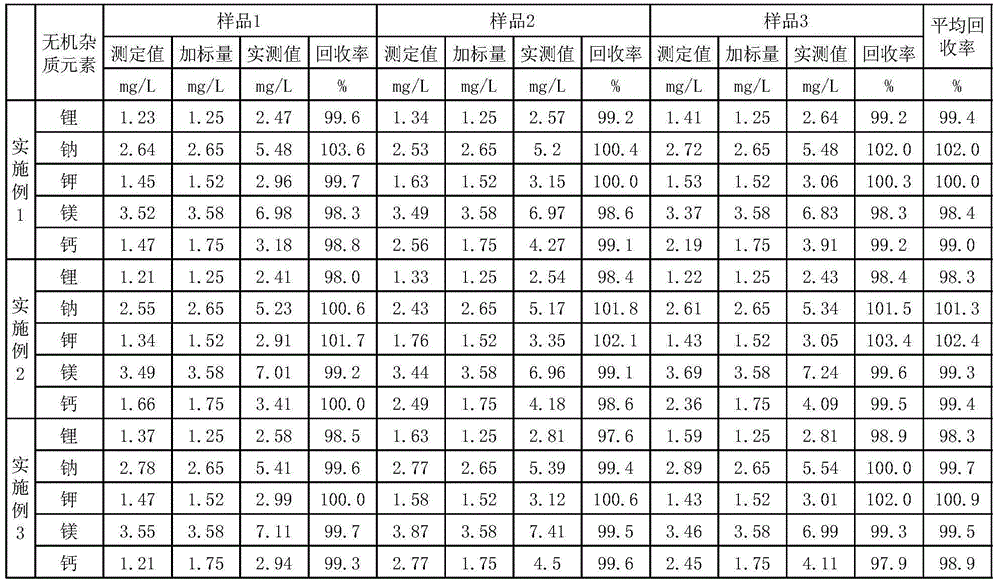

Examples

Embodiment 1

[0022] (1) Accurately weigh 1g (accurate to 0.0001g) of boric acid sample and place it in a PFA jar;

[0023] (2) The mass ratio of the boric acid sample and the spectrally pure methanol reagent is 1:8, directly adding the spectrally pure methanol reagent into the open PFA jar, and stirring evenly;

[0024] (3) Place the PFA jar in a boiling water bath at 78°C and heat it for 80 minutes, then stop heating to obtain a boric acid sample solution;

[0025] (4) After the boric acid sample solution is cooled, use secondary deionized water to make up the volume in a 5mL volumetric flask;

[0026] (5) ICP-OES was used to analyze the content of lithium, sodium, potassium, magnesium and calcium in the boric acid sample solution after constant volume.

[0027] Among them, the test conditions of ICP-OES are as follows:

[0028] Power 1100W; Plasma gas 13L / min; Auxiliary gas 0L / min; Sheath gas 0.3L / min; Atomizing gas 0.8L / min; The most sensitive line was used; the light chamber was pur...

Embodiment 2

[0031] (1) Accurately weigh 1g (accurate to 0.0001g) of boric acid sample and place it in a PFA jar;

[0032] (2) The mass ratio of the boric acid sample and the spectrally pure methanol reagent is 1:18, and the spectrally pure methanol reagent is directly added to the open PFA jar, and stirred evenly;

[0033] (3) Place the PFA jar in a boiling water bath at 120°C and heat it for 45 minutes, then stop heating to obtain a boric acid sample solution;

[0034] (4) After the boric acid sample solution is cooled, use secondary deionized water to make up the volume in a 5mL volumetric flask;

[0035] (5) ICP-OES was used to analyze the content of lithium, sodium, potassium, magnesium and calcium in the boric acid sample solution after constant volume.

[0036] Among them, the test conditions of ICP-OES are as follows:

[0037] Power 1100W; Plasma gas 13L / min; Auxiliary gas 0L / min; Sheath gas 0.3L / min; Atomizing gas 0.8L / min; The most sensitive line was used; the light chamber wa...

Embodiment 3

[0040] (1) Accurately weigh 1g (accurate to 0.0001g) of boric acid sample and place it in a PFA jar;

[0041] (2) The mass ratio of the boric acid sample and the spectrally pure methanol reagent is 1:12, and the spectrally pure methanol reagent is directly added to the open PFA jar, and stirred evenly;

[0042] (3) Place the PFA jar in a boiling water bath at 100°C and heat it for 60 minutes, then stop heating to obtain a boric acid sample solution;

[0043] (4) After the boric acid sample solution is cooled, use secondary deionized water to make up the volume in a 5mL volumetric flask;

[0044] (5) ICP-OES was used to analyze the content of lithium, sodium, potassium, magnesium and calcium in the boric acid sample solution after constant volume.

[0045] Among them, the test conditions of ICP-OES are as follows:

[0046] Power 1100W; Plasma gas 13L / min; Auxiliary gas 0L / min; Sheath gas 0.3L / min; Atomizing gas 0.8L / min; The most sensitive line was used; the light chamber was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com