Preparation method for HDI rigid-flex PCB interlayer blind hole all-copper filling

A rigid-flex board, copper filling technology, applied in the direction of printed circuit manufacturing, processing step sequence, printed circuit, etc., can solve the problem of improving the difficulty of full copper filling of rigid-flex board, hindering the development of HDI rigid-flex board, and filling potions. It is difficult to reach the bottom of the hole and other problems, so as to save the production cost and production time, improve the production efficiency and production efficiency, and improve the thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

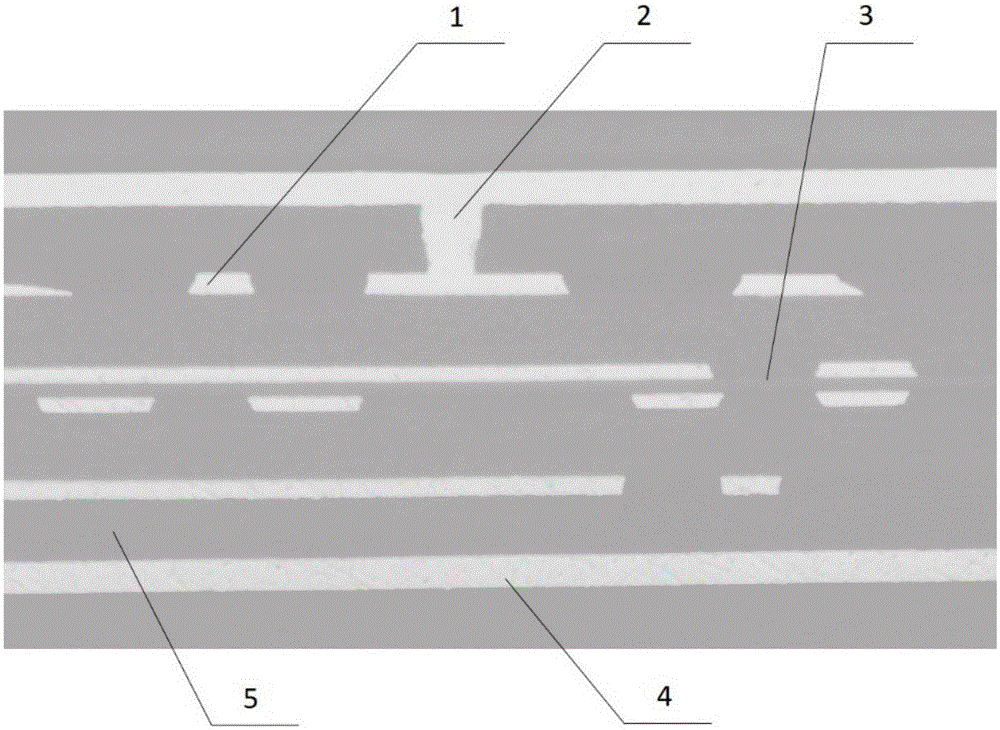

[0036] see figure 1 and 2 , a full copper filling of blind holes between HDI rigid-flex boards, prepared according to the following steps:

[0037] 1) Prepare a double-sided copper-clad laminate, with copper foil with a thickness of 18 μm on the upper and lower surfaces, and a thickness of the interposer layer of 75 μm. Apply a dry film to one side of the double-sided copper-clad laminate, and use a horizontal copper-reducing wire to reduce copper on one side on the side without the dry film. The thickness of the copper foil on the copper-reducing side is 7 μm.

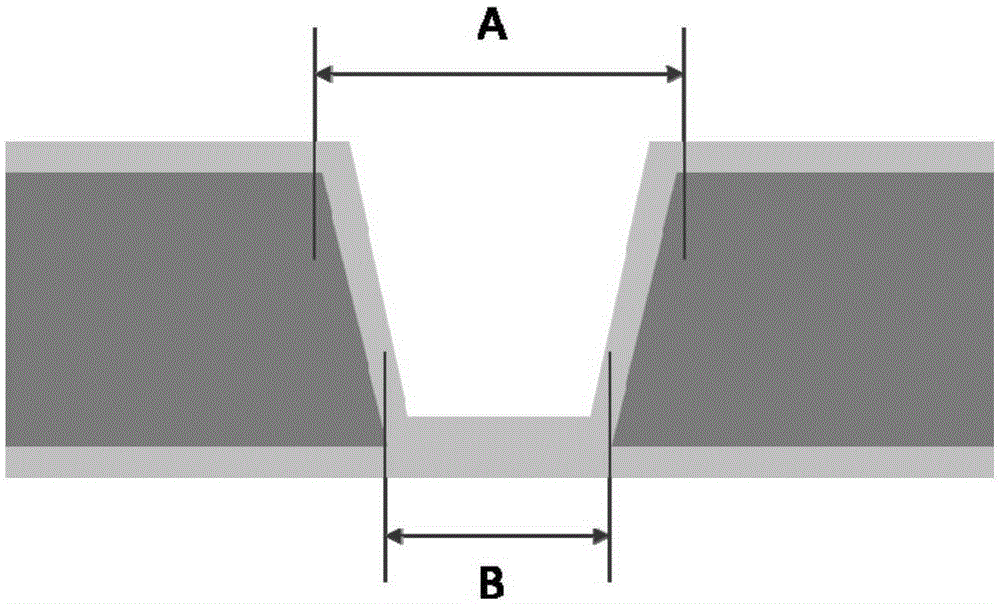

[0038] 2) Use CAD software to make the drilling data of the blind holes between the HDI rigid-flex boards, and use UV laser drilling to drill the copper-reducing side of the double-sided copper-clad laminate according to the drilling data, and the shape of the prepared blind holes It is an inverted trapezoid, A is the upper aperture of the blind hole of the HDI rigid-flexible board, and B is the lower aperture of th...

Embodiment 2

[0043] The steps of this embodiment are basically the same as those of Embodiment 1, the difference is that in step 5), the components of the electroplating potion used for hole filling copper plating include 220g / L of copper sulfate pentahydrate, 50g / L of sulfuric acid, 50ppm of chloride ions, accelerated agent 1.0mL / L), inhibitor 15mL / L, leveling agent 15mL / L, the blind hole is filled and leveled after electroplating, and the line is leveled.

Embodiment 3

[0045] The steps of this embodiment are basically the same as those of Embodiment 1, the difference is that in step 5), the components of the electroplating potion used for hole filling copper plating include 240g / L of copper sulfate pentahydrate, 60g / L of sulfuric acid, 60ppm of chloride ions, accelerated The agent is 1.2mL / L, the inhibitor is 18mL / L, and the leveling agent is 18mL / L. After electroplating, the blind hole is filled and leveled, and the line is leveled.

[0046]A preparation method for full copper filling of blind holes between layers of HDI rigid-flexible boards in the above embodiment uses a horizontal copper reduction wire to reduce copper on one side of a double-sided copper clad laminate, and uses a UV laser to drill blind holes on the copper-reducing side. Then remove the glue, sink copper, and finally use the blind hole electroplating process to fill the blind hole with copper, so that the rigid-flexible board reaches the interlayer interconnection, savin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com