Preparation method of porous titanium dioxide thin film for dye-sensitized solar cell

A technology of porous titanium dioxide and solar cells, applied in photosensitive equipment, photovoltaic power generation, capacitor parts and other directions, can solve the problems of restricting the industrialization development of dye-sensitized solar cells, poor compatibility and poor durability of titanium dioxide nanoparticles, etc. Photoelectric properties, good crystallization, uniform pore distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

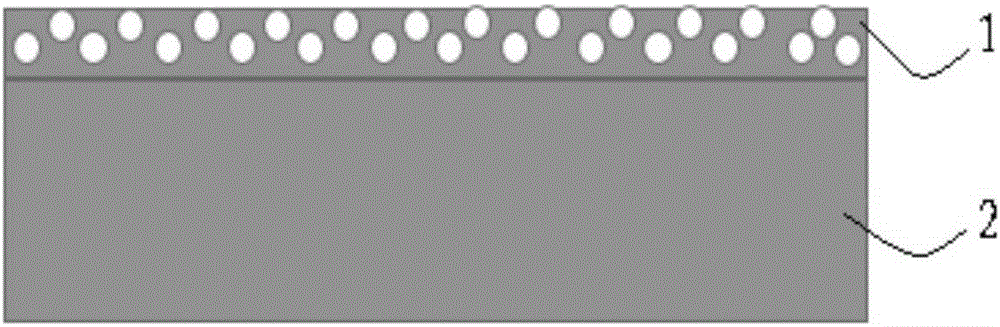

[0014] Such as figure 1 Shown, the invention provides a kind of preparation method of dye-sensitized solar cell porous titanium dioxide film, it comprises the following steps:

[0015] Step A, providing a base material 2 with a clean surface, and depositing a titanium-containing organic-inorganic composite film on the surface of the base material 2 using molecular layer deposition technology;

[0016] In step B, the material obtained in step A is heat-treated at 400-600° C. for 2-5 hours to obtain a porous titanium dioxide film 1 .

[0017] Preferably, in the step A, the base material 2 is cleaned with an organic solvent and deionized water under ultrasonic conditions, and then the cleaned base material 2 is blown dry with compressed nitrogen to obtain a surface-clean base material 2 . Specifically, the organic solvent is one of isopropanol, alcohol, chloroform or acetone.

[0018] Preferably, said step B includes,

[0019] Step A1, put the base material 2 with clean surfac...

Embodiment 1

[0031] First, clean the FTO conductive glass with isopropanol under ultrasonic conditions, and then dry the cleaned FTO conductive glass with compressed nitrogen;

[0032] Next, put the FTO conductive glass into the reaction chamber of the atomic layer deposition equipment with a temperature of 80°C, and purging it with 50 sccm high-purity nitrogen for 5 minutes;

[0033] Then, TiCl with a purity of 97% 4 Heating to 60°C forms TiCl 4 vapor, and pulse the TiCl 4 The steam is sent into the reaction chamber, the pulse time is 0.05s, the exposure time is 8s, and then purged with high-purity nitrogen, the purge time is 15s;

[0034] Next, heat ethylene glycol to 100°C to form ethylene glycol vapor, and then send it into the reaction chamber in the form of pulses, the pulse time is 0.1s, the exposure time is 20s, and then purged with high-purity nitrogen, the purge time is 30s, a deposition cycle is completed, that is, a layer of titanium-containing organic-inorganic composite fi...

Embodiment 2

[0039] First, clean the ITO conductive glass with alcohol under ultrasonic conditions, and then dry the cleaned ITO conductive glass with compressed nitrogen;

[0040]Secondly, put the ITO conductive glass into the reaction chamber of the atomic layer deposition equipment with a temperature of 150°C, and purging with 100 sccm high-purity nitrogen for 30 minutes;

[0041] Then, titanium tetraisopropoxide with a purity of 97% is heated to 65°C to form titanium tetraisopropoxide vapor, and the titanium tetraisopropoxide vapor is sent into the reaction chamber in pulse form, the pulse time is 0.2s, and the exposure time is for 15s, and then purged with high-purity nitrogen for 30s;

[0042] Next, heat the glycerol to 120°C to form glycerol vapor, and then send it into the reaction chamber in a pulse form, the pulse time is 1s, the exposure time is 30s, and then purged with high-purity nitrogen, the purge time is 45s , completing a deposition cycle, that is, depositing a layer of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com