Clumpy hydrophobic phenolic resin/silicon dioxide compounded aerogel and preparation method thereof

A composite airgel and silica technology, which is applied in the field of bulk hydrophobic phenolic resin/silica composite airgel and its preparation, can solve the problems of difficulty in obtaining bulk materials, increasing costs, and prolonging production cycle. To achieve the effect of convenient industrial production, short production cycle and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention also provides the preparation method of any above-mentioned massive hydrophobic phenolic resin / silicon dioxide composite airgel, and described method comprises the following steps:

[0036] (1) Mix a certain amount of phenols, aldehydes, aminosilanes, siloxanes with one or two hydrocarbon groups, distilled water and alcohols, and stir for 10-120 minutes to obtain a transparent sol; among them, phenols, aldehydes, The molar ratio of aminosilane, siloxane containing one or two hydrocarbon groups, distilled water, and alcohols is 1: (0.5-7.5): (0.1-3.5): (0.1-8.5): (1.5-45): (10 ~70), wherein the molar ratio of aminosilane is preferably 0.7~2.5, the molar ratio of distilled water is preferably 18~45, and the molar ratio of alcohols is preferably 20~50;

[0037] (2) The above-mentioned transparent sol is gelled, the gelation temperature is 20-95°C, preferably the gelation temperature is 60-70°C, and the gelation time is 1-20h to obtain a phenolic resin...

Embodiment 1

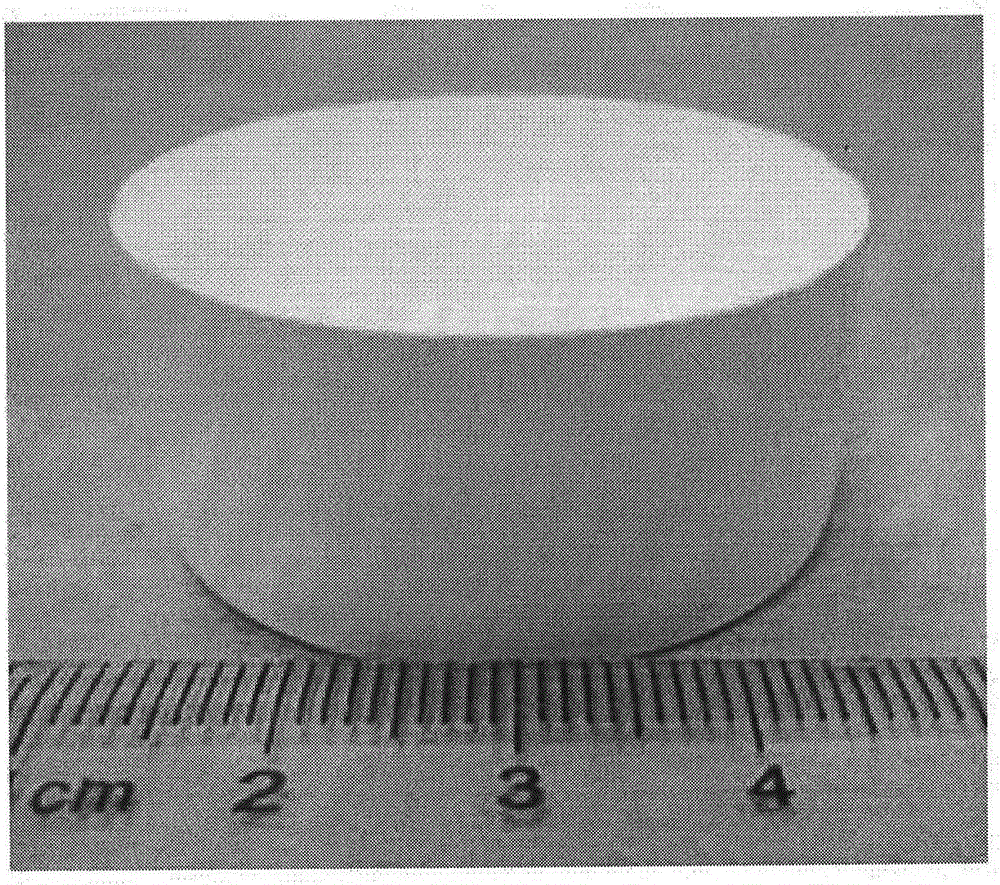

[0056] Mix 1.5g of phenol, 1.5g of formaldehyde, 2.5g of 3-aminopropyltrimethoxysilane, 3.0g of methyltrimethoxysilane, 5.0g of distilled water, and 20g of ethanol, and mix them thoroughly for 10 minutes to obtain a transparent sol, which gels at 50°C 10h to get a wet gel. The wet gel was dried for 48 hours under normal pressure at 50°C to obtain a phenolic resin / silica composite airgel. The density of the above-mentioned phenolic resin / silica composite airgel is 0.20 g cm -3 , porosity 88.2%, BET specific surface area 200m 2 g -1 , the contact angle between distilled water and the surface is 128°, the pore size distribution is 10-100nm, the elastic modulus is 5MPa, the compressive strength is 11.5MPa, and the thermal conductivity is 0.035W m -1 k -1 , the silica content is 35%. From figure 1 It can be seen from the figure that the composite airgel is a block, and the actual color is beige.

Embodiment 2

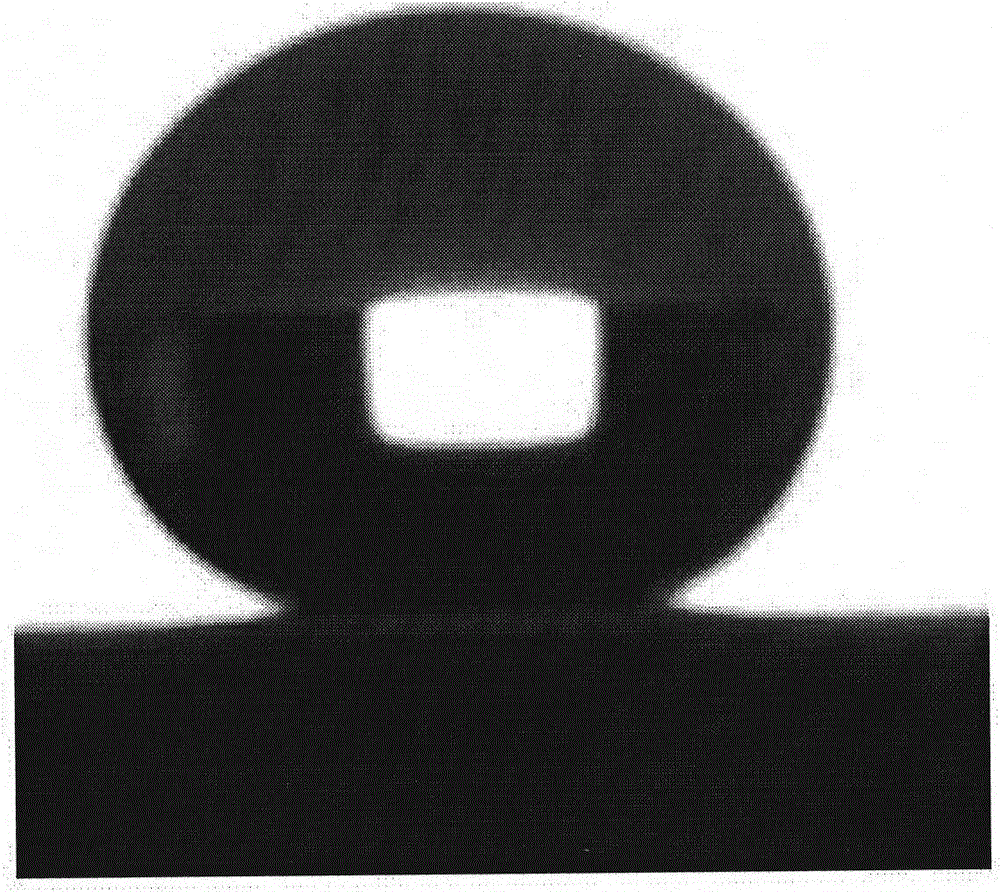

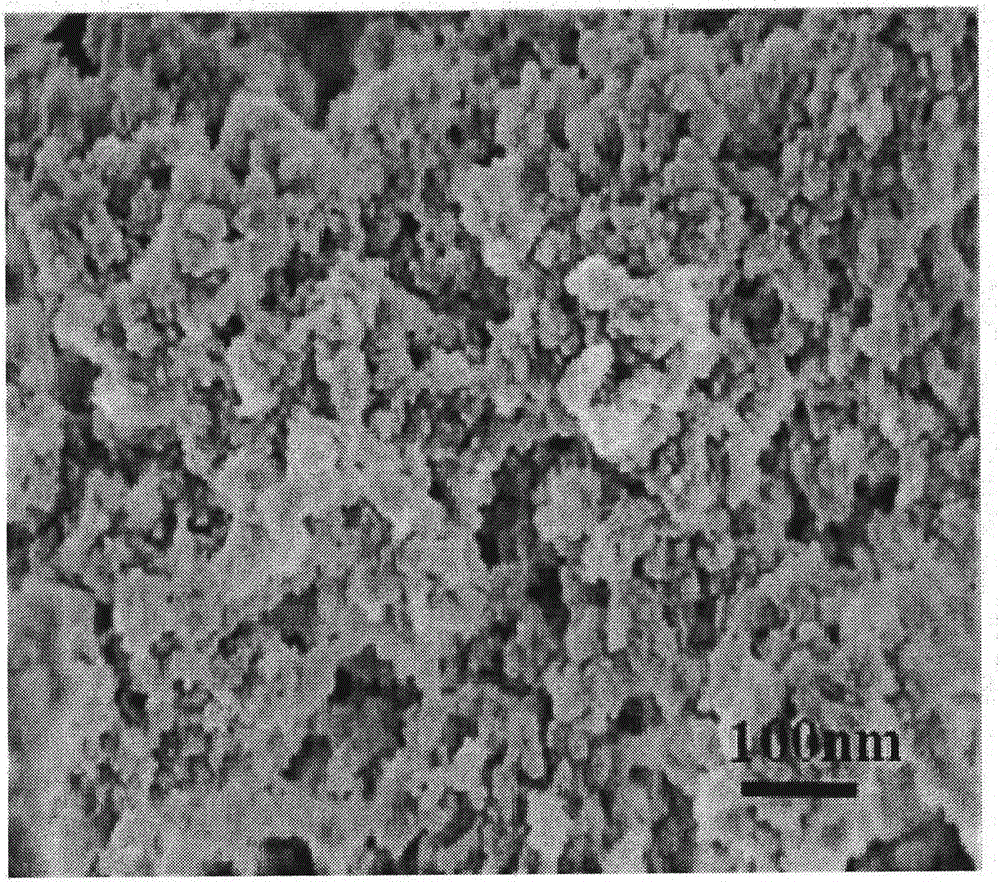

[0058] Mix 1.5g of phenol, 2.0g of formaldehyde, 2.5g of 3-aminopropyltrimethoxysilane, 3.5g of methyltriethoxysilane, 5.0g of distilled water, and 25g of ethanol, and mix them thoroughly for 50 minutes to obtain a transparent sol. Gel 5h to get wet gel. The wet gel was dried at 40°C under normal pressure for 48 hours to obtain a phenolic resin / silica composite airgel. The density of the above-mentioned phenolic resin / silica composite airgel is 0.15g cm -3 , porosity 91.0%, BET specific surface area 570m 2 g -1 ,From figure 2 It can be seen that the contact angle between distilled water and the surface is 138°, from image 3 and Figure 4 It can be seen that the pore size distribution is 7-120nm, the elastic modulus is 2MPa, the compressive strength is 3.5MPa, and the thermal conductivity is 0.03W m -1 k -1 , the silica content is 47%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com