Deep frying coating powder and making process thereof

A production process and powder-coating technology, which is applied in food ingredients as taste improvers, food science, food preservation, etc., can solve the problems of lack of antifreeze performance, poor water retention performance, poor film-forming performance, etc., and achieve improved freeze-thaw performance. Stability, strong water retention, good film-forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

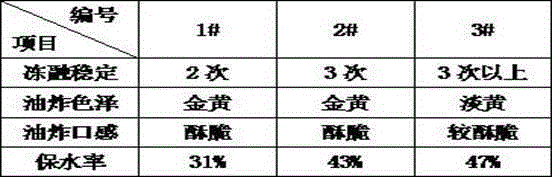

Examples

Embodiment 1

[0026] A kind of deep-fried wrapping flour, its composition and ratio are, cassava acetate starch: corn acetate starch=4:6, and its manufacturing process is as follows:

[0027] 1. Mix 40g of tapioca raw starch and 60g of corn raw starch, and add water to adjust to 22.5Be' starch milk and mix evenly.

[0028] 2. Use 6% alkali solution to adjust the pH of starch milk to 8.9, and stir for 30 minutes to fully activate the starch.

[0029] 3. At 5-40°C, add 4% acetic anhydride to the starch milk drop by drop, and add 6% alkali solution dropwise at the same time to keep the pH value of the starch milk stable at 8.2. Continue to add alkali dropwise after the addition of acetic anhydride is completed. The solution ensures that the pH value is basically stable.

[0030] 4. Adjust the pH to 6 with 10% dilute hydrochloric acid to terminate the reaction.

[0031] 5. Pass the modified starch milk through a 200-mesh sieve to remove granular impurities. After desanding by a sand remover, ...

Embodiment 2

[0033] A kind of deep-fried wrapping flour, its composition and ratio are, cassava acetate starch: corn acetate starch=6:4, and its manufacturing process is as follows:

[0034] 1) Add water to raw tapioca starch and raw corn starch respectively to make 23.5Be′ starch milk.

[0035] 2) Use alkaline solution to adjust the pH of starch milk to 9.6, stir to fully activate the starch.

[0036] 3) Under the condition of 5-40°C, add 2% acetic anhydride to the starch milk dropwise, and at the same time add the alkali solution dropwise to keep the pH value of the starch milk at 9.0. After the addition of acetic anhydride, continue to drop the alkali solution to ensure the pH The value is basically stable.

[0037] 4) Adjust the pH to 7.5 with 15% dilute hydrochloric acid to terminate the reaction.

[0038] 5) Pass cassava modified starch milk and corn modified starch milk through 200-mesh sieve respectively to remove granular impurities, go through desand remover to remove sand, was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com