Packaging member for reducing width of lead wire by using grinding technology and manufacture process thereof

A grinding process and manufacturing process technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as cost reduction, waste of wiring area, and inability to etch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

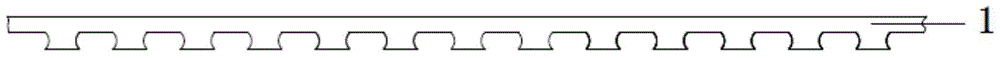

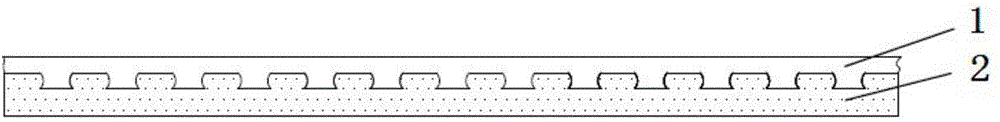

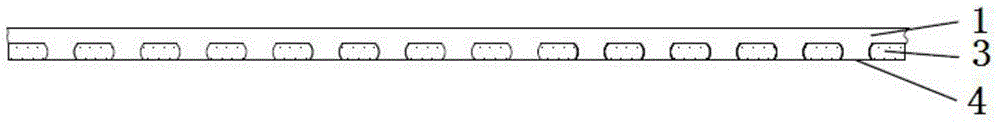

[0025] The following is a detailed description of this product in conjunction with the accompanying drawings.

[0026] A package that adopts a grinding process to reduce the width of the lead, mainly composed of a chip 7, a bonding wire 8, an adhesive 9, an upper plastic package 10, an inner lead 6, pins 4, a ground plastic package 3 and solder balls 11 , the chip 7 is bonded on the inner lead 6 by adhesive 9, the bonding wire 8 connects the chip 7 and the inner lead 6, the lower part of the inner lead 6 is filled with a ground plastic package 3, and the lower end of the inner lead 6 is a pin 4. A solder ball 11 is connected to the pin 4, and the upper plastic package 10 surrounds the chip 7, the bonding wire 8, the adhesive 9 and the inner lead 6.

[0027] The chip 7 can also be bonded on the carrier 12 through the adhesive 9 .

[0028] The chip 7 can also be bonded on the ground plastic package 3 through the adhesive 9 .

[0029] Pin 4 can also be plated with nickel-pallad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com