High-throughput screening method for bacillus circulans

A technology of bacillus circulans and screening methods, which is applied in the fields of fermentation engineering and microbial breeding, can solve the problems of heavy screening workload and low screening efficiency, and achieve the effects of increasing screening capacity, simple screening methods, and increasing sample processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Calculation method of enzyme activity:

[0039] 1. Reagent preparation

[0040] (1) Z-buffer

[0041] Dissolve 16.1g disodium hydrogen phosphate, 5.5g sodium dihydrogen phosphate, 0.75g potassium chloride, 0.246g magnesium sulfate and 2.7mL 2-mercaptoethanol in 800mL water, add 2mol / L sodium hydroxide solution, adjust the pH to 6.0± 0.05, detected with a pH meter. Transfer the solution to a 1000mL volumetric flask, dilute to volume with water, and mix well.

[0042] (2) ONPG (o-nitrophenyl-β-D-galactopyranoside) solution

[0043] Dissolve 250.0mg of ONPG with 75mL Z-buffer solution, transfer the solution to a 100mL volumetric flask, and use Z-buffer solution to make up volume as a substrate.

[0044] (3) Stop solution

[0045]Use water as the solvent, dissolve 10g of sodium carbonate, and transfer to a 100mL volumetric flask to constant volume.

[0046] (4) Test sample preparation

[0047] Test enzyme samples were prepared such that the final solution contained 0...

Embodiment 2

[0065] Follow the steps below for high-throughput screening of Bacillus circulans:

[0066] (1) starting bacterium activation: the bacillus circulans (concentration of spore is 10 5 ~10 8 individuals / mL) as the initial strain, streak culture, the initial strain was inoculated in 100mL fermentation medium after three times of slant LB plate activation, cultured in a shake flask at 37°C for 40h and then centrifuged, the supernatant was taken for β-half Lactosylase activity assay, its assay result is as shown in table 1:

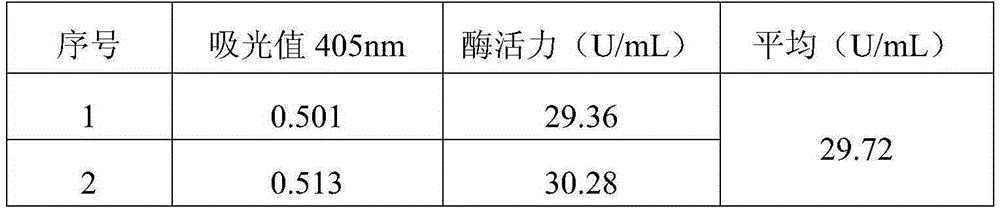

[0067] Table 1 Initial strain β-galactosidase activity

[0068]

[0069] Pick a ring of slant strains in fresh LB medium, culture at 37°C for 6 hours, centrifuge at 10,000rmp for 10 minutes, collect the bacteria, resuspend them in sterile water, filter them through absorbent cotton, and place them in a small Erlenmeyer flask filled with glass beads , shake evenly, prepare a single-cell suspension, and adjust the cell concentration to 10 after counting wit...

Embodiment 3

[0078] Follow the steps below for high-throughput screening of Bacillus circulans:

[0079] (1) starting bacterium activation: the bacillus circulans (concentration of spore is 10 8 cells / mL) as the initial strain, carry out streak culture, pick a ring of slanted bacteria on a fresh LB plate, culture at 30°C for 12 hours, centrifuge at 10,000rmp for 10min, collect the bacteria, resuspend in sterile water, and pass through absorbent cotton After filtering, place it in a small Erlenmeyer flask equipped with glass beads, oscillate evenly, and prepare a single-cell suspension. After counting with an optical microscope, adjust the cell concentration to 10 6 About one / mL, spare;

[0080] (2) UV mutagenesis: place 5 mL of the cell suspension in step (1) at a distance of 25 cm from a 30w UV lamp, and irradiate for 30 min;

[0081] (3) Chlorine mutagenesis: after ultraviolet irradiation treatment, put the bacteria solution in ice bath for 2 hours, put it into fresh LB culture medium,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com