Ceramic containing pyrochlore phase zirconic acid gadolinium powder and preparation method of ceramic

A technology of phase zirconate and pyrochlore, which is applied in the field of ceramics and its preparation, can solve the problems of unsatisfactory structure of gadolinium zirconate ceramics, difficulty in preparation of gadolinium zirconate ceramics, unsatisfactory mechanical properties at room temperature, etc., and achieve sintering time and production The effect of short cycle, good compactness and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

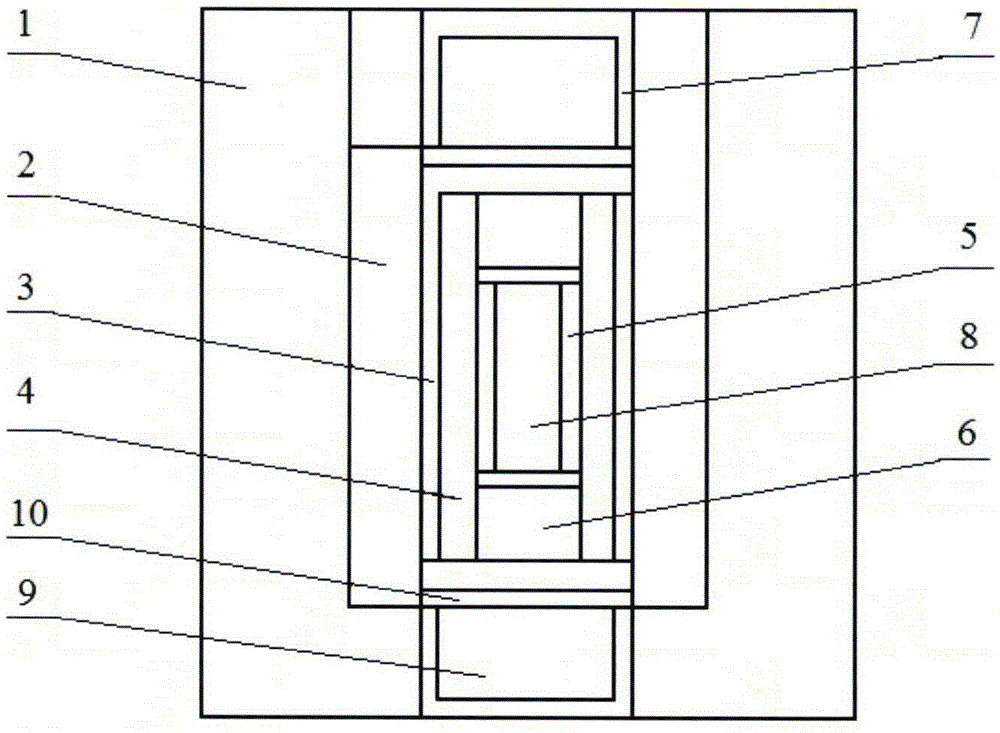

Method used

Image

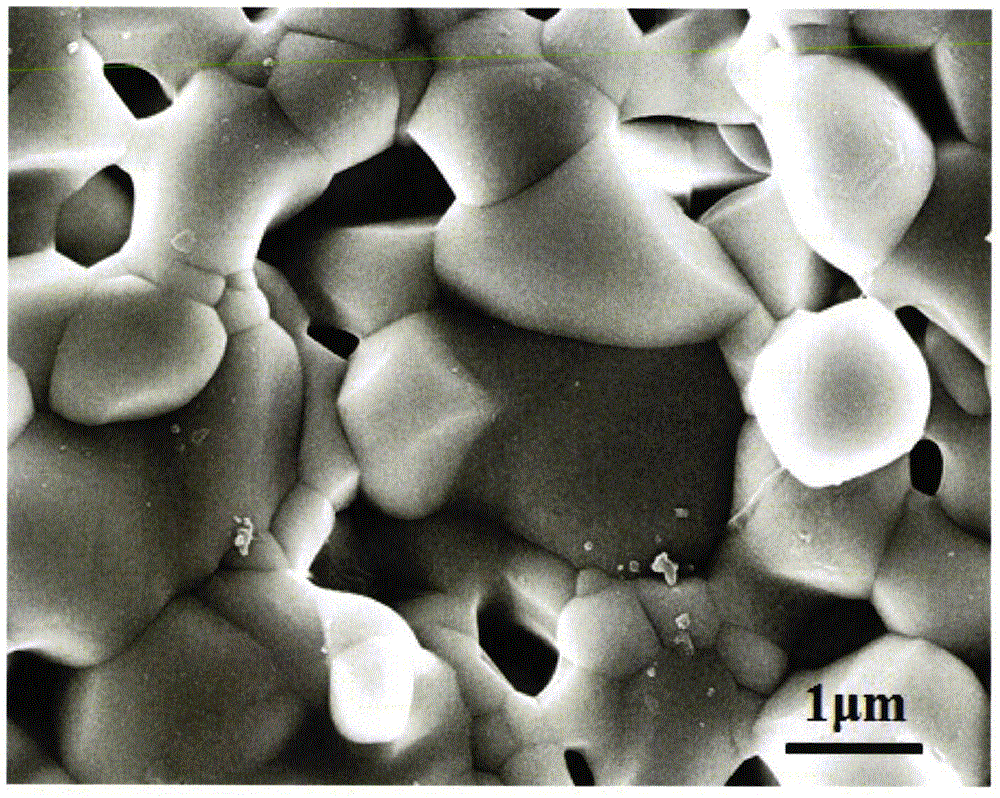

Examples

Embodiment 1

[0037] A method for preparing ceramics containing pyrochlore phase gadolinium zirconate powder, comprising the following steps:

[0038] (1) Mixing of ingredients: the following by weight percentage, with gadolinium zirconate 20% (average particle size 35nm), gadolinium oxide 45% (150 mesh), zirconia 30% (150 mesh), sintering aid yttrium oxide (200 mesh ) 5%, carry out its thorough mixing, obtain the powder body after mixing.

[0039] (2) Grinding and drying: Add absolute ethanol to the mixed powder, grind for 2 hours until the particles of the mixture are 150 mesh, put it into a constant temperature blast drying oven at 60-90°C for 1 hour to obtain a composite powder.

[0040] (3) Cold isostatic granulation: The composite powder is pressed under a pressure of 200MPa by cold isostatic pressing, taken out, crushed, and passed through a 1-4mm square hole sieve to obtain uniform granules.

[0041] (4) Raw material forming: Under the pressure condition of 15 MPa, the uniform part...

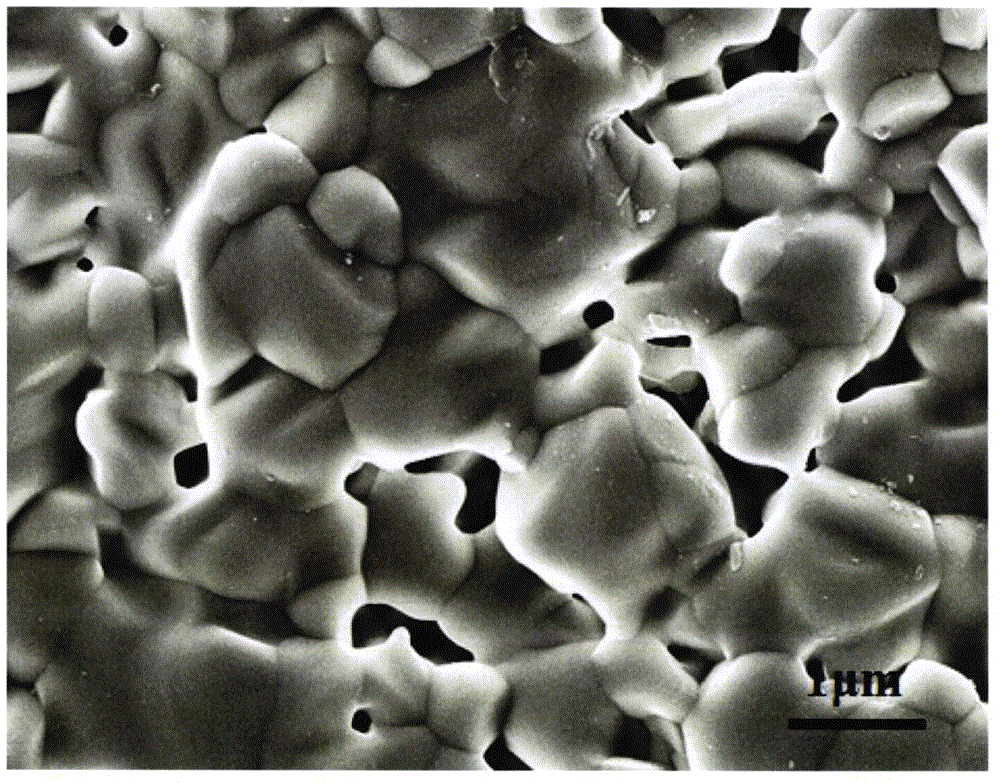

Embodiment 2

[0046]A method for preparing ceramics containing pyrochlore phase gadolinium zirconate powder, comprising the following steps:

[0047] (1) Mixing of ingredients: the following by weight percentage, with gadolinium zirconate 80% (average particle size 35nm), gadolinium oxide 9% (150 mesh), zirconia 6% (150 mesh), sintering aid yttrium oxide (200 mesh ) 5%, carry out its thorough mixing, obtain the powder body after mixing.

[0048] (2) Grinding and drying: Add absolute ethanol to the mixed powder, grind for 2 hours until the particles of the mixture are 150 mesh, put it into a constant temperature blast drying oven at 60-90°C for 1 hour to obtain a composite powder.

[0049] (3) Cold isostatic granulation: The composite powder is pressed under a pressure of 200MPa by cold isostatic pressing, taken out, crushed, and passed through a 1-4mm square hole sieve to obtain uniform granules.

[0050] (5) Raw material forming: Under the pressure condition of 15 MPa, the uniform particl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com