Normal/low-temperature chemical conversion solution for 35CrMnSi steel and preparing method thereof

A chemical conversion, normal and low temperature technology, applied in the direction of metal material coating process, etc., can solve the problems of unsuitable carbon content, difficult medical stainless steel, easy to produce precipitation, etc., to improve surface protection performance, easy to operate, and simple to use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A normal-low temperature chemical conversion solution for 35CrMnSi steel, which comprises the following ingredients in parts by weight: 30 parts of nitric acid, 10 parts of phosphoric acid, 25 parts of zinc oxide, 5 parts of reduced iron powder, 7 parts of composite accelerator, and add water to 1000 parts. The composite accelerator consists of citric acid and sodium chlorate.

[0027] The preparation method of the above-mentioned chemical conversion solution is as follows: first, zinc oxide, nitric acid, and phosphoric acid are added to the beaker in turn, and magnetically stirred until completely dissolved; secondly, the composite accelerator is added, stirred until completely dissolved, and water is added to 1000 parts; finally, iron powder is added to into the solution, take out the iron powder after aging for 14 hours, and adjust the pH value to 2.75.

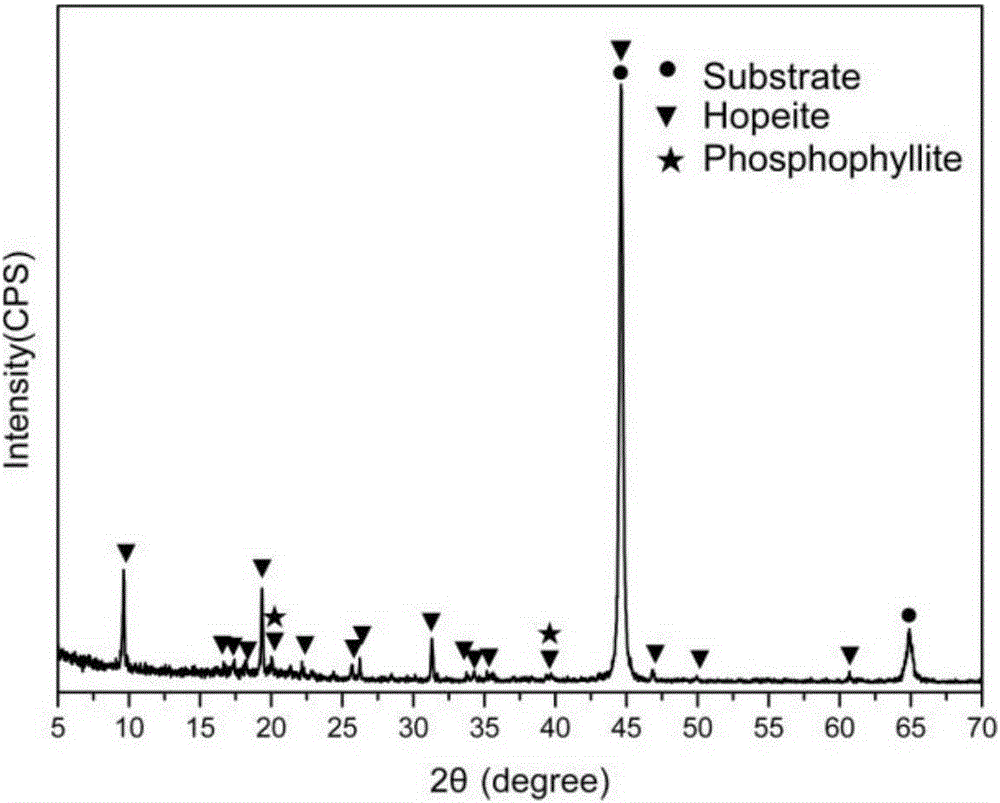

[0028] Depend on figure 1 It can be seen that the phase composition of the film layer is zinc phosphate (Zn 3 (...

Embodiment 2

[0030] A normal-low temperature chemical conversion solution for 35CrMnSi steel, which comprises the following ingredients in parts by weight: 25 parts of nitric acid, 5 parts of phosphoric acid, 20 parts of zinc oxide, 3 parts of reduced iron powder, 10 parts of composite accelerator, and add water to 1000 parts. The composite accelerator is mainly composed of citric acid and sodium chlorate.

[0031] The preparation method of the above-mentioned chemical conversion solution is as follows: first, zinc oxide, nitric acid, and phosphoric acid are added to the beaker in turn, and magnetically stirred until completely dissolved; secondly, the composite accelerator is added, stirred until completely dissolved, and water is added to 1000 parts; finally, iron powder is added to into the solution, take out the iron powder after aging for 10 hours, and adjust the pH value to 2.5.

Embodiment 3

[0033]A normal-low temperature chemical conversion solution for 35CrMnSi steel, which comprises the following ingredients in parts by weight: 15 parts of nitric acid, 15 parts of phosphoric acid, 20 parts of zinc oxide, 3 parts of reduced iron powder, 7 parts of composite accelerator, and add water to 1000 parts. The composite accelerator is mainly composed of citric acid and sodium chlorate.

[0034] The preparation method of the above-mentioned chemical conversion solution is as follows: first, zinc oxide, nitric acid, and phosphoric acid are added to the beaker in turn, and magnetically stirred until completely dissolved; secondly, the composite accelerator is added, stirred until completely dissolved, and water is added to 1000 parts; finally, iron powder is added to into the solution, after aging for 6 hours, take out the iron powder, and adjust the pH value to 2.0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com