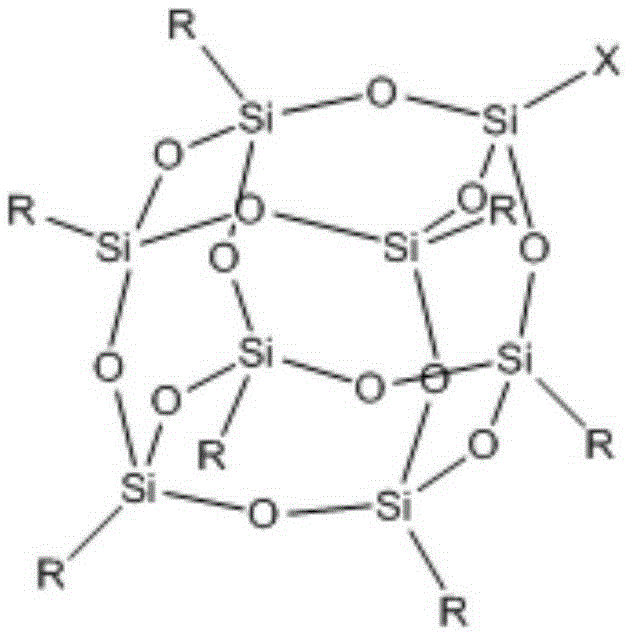

Cage-shaped oligomerization polyhedral silsesquioxane with eight phenolic hydroxyl groups and preparation method thereof

A technology of octaphenol hydroxyl cage and silsesquioxane, which is applied in the direction of silicon organic compounds, etc., to achieve the effects of flexible and diverse preparation methods, high purity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The chemical reaction process involved in the preparation method of octaphenol hydroxy clathrate silsesquioxane of the present invention is as follows (synthetic route):

[0057] (1), add p-vinylphenol

[0058]

[0059] (2), add p-acetoxystyrene

[0060]

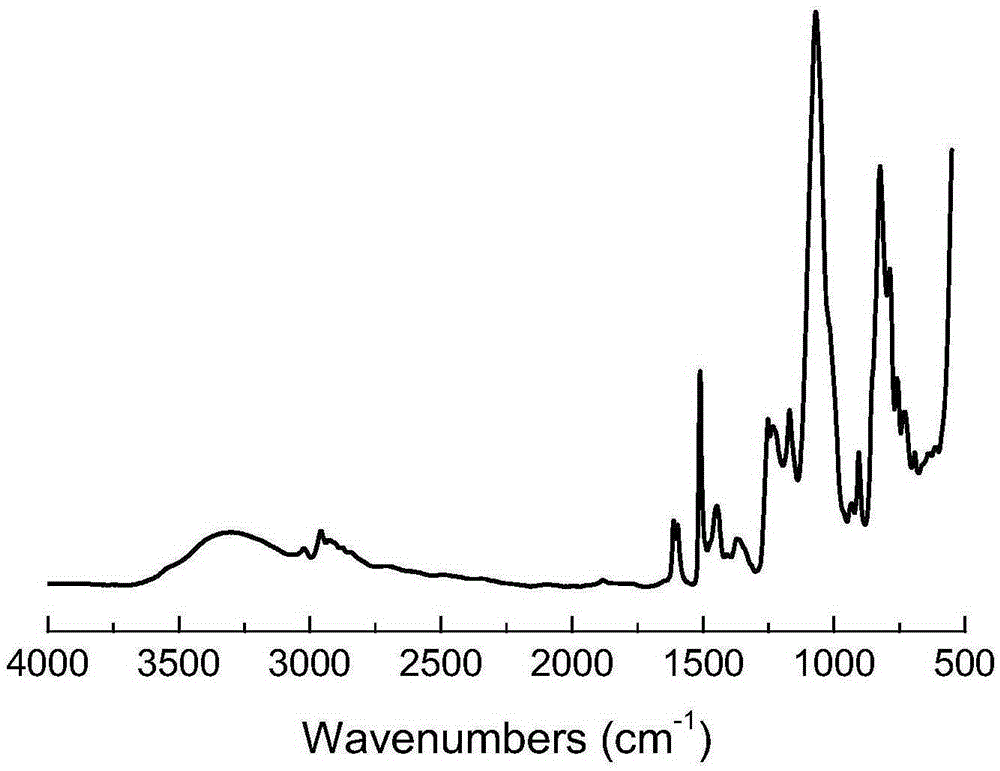

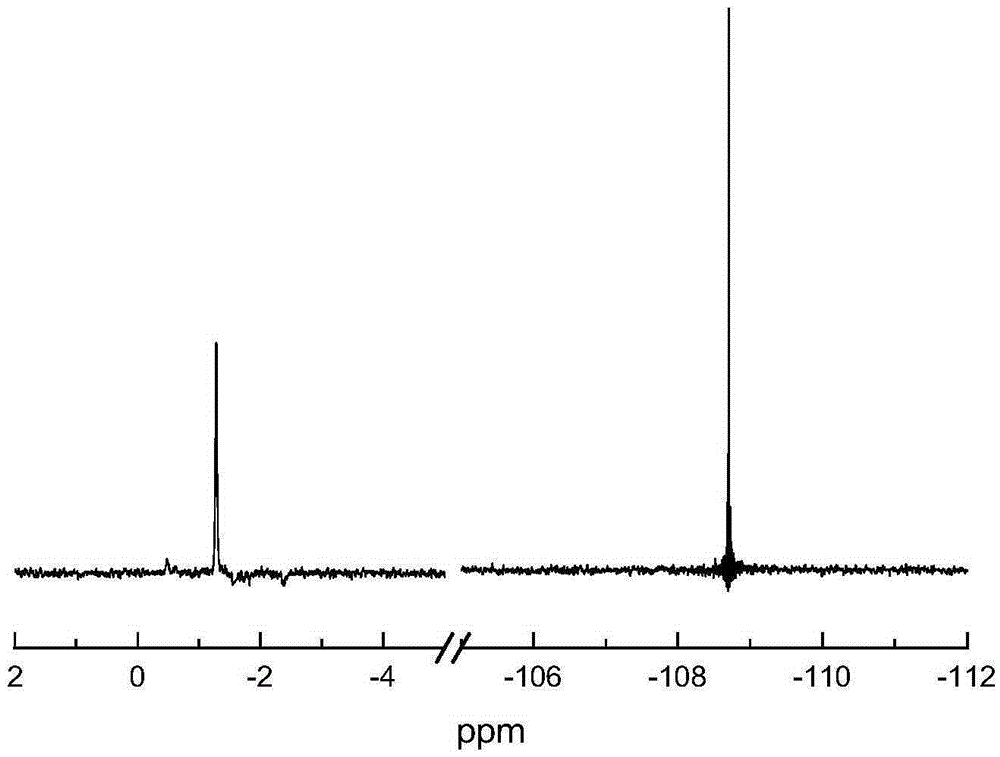

Embodiment 1

[0062] Weigh 8.2g of tetramethylammonium hydroxide pentahydrate, 45ml of methanol, and 8.1g of deionized water, place them in a 100ml three-neck flask, pass in nitrogen or argon, condensate, stir magnetically in an ice-water bath for 30 minutes, add 10ml of normal Tetraethyl silicate was added dropwise to the above mixture, reacted in an ice-water bath for 6 hours, then rose to room temperature and continued to react for 24 hours. After the reaction is over, add the above mixed solution dropwise to 60ml of n-hexane solution with a volume fraction of dimethylchlorosilane of 20vol%, pass through nitrogen or argon protective gas, stir the reaction in an ice-water bath for 12 hours, stop the reaction, and mix the reaction Pour the solution into a 1000ml separating funnel, wash with deionized water until neutral, let it stand, separate the upper organic phase, dry the organic phase with anhydrous magnesium sulfate, remove the solvent by rotary evaporation to obtain 3.32g of white gr...

Embodiment 2

[0066]Weigh 5g of tetramethylammonium hydroxide pentahydrate, 40ml of methanol, and 5.0g of deionized water, place them in a 100ml three-neck flask, pass in nitrogen or argon, condensed water, stir magnetically in an ice-water bath for 30 minutes, and add 6g of orthosilicon Acetate tetraethyl ester was added dropwise to the above mixture, reacted in an ice-water bath for 6 hours, then rose to room temperature and continued to react for 24 hours. After the reaction is over, add the above mixed solution dropwise to 40ml of n-hexane solution with a volume fraction of dimethylchlorosilane of 20vol%, pass through nitrogen or argon protective gas, stir and react in an ice-water bath for 12 hours, stop the reaction, and mix the reaction Pour the solution into a 1000ml separating funnel, wash with deionized water until neutral, let it stand, separate the upper organic phase, dry the organic phase with anhydrous magnesium sulfate, remove the solvent by rotary evaporation to obtain 2.10g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com