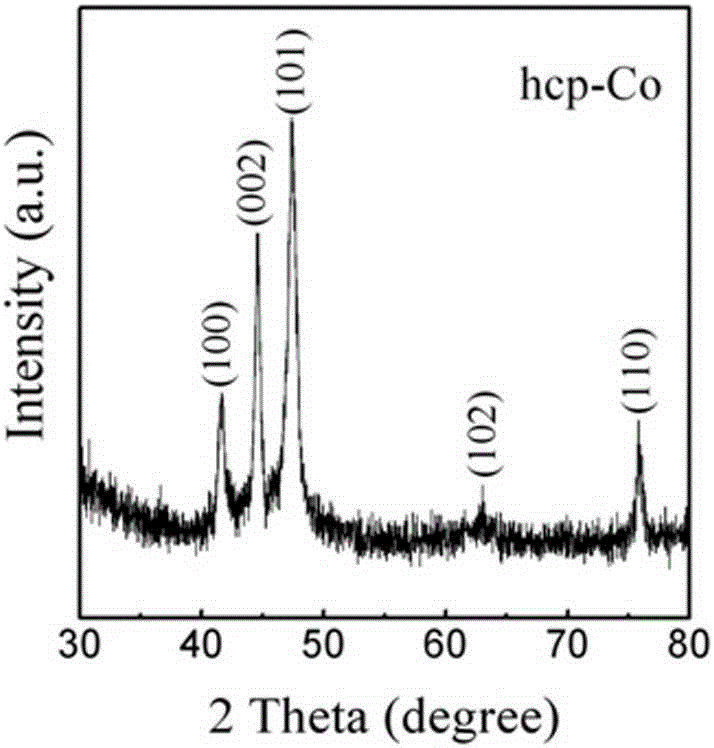

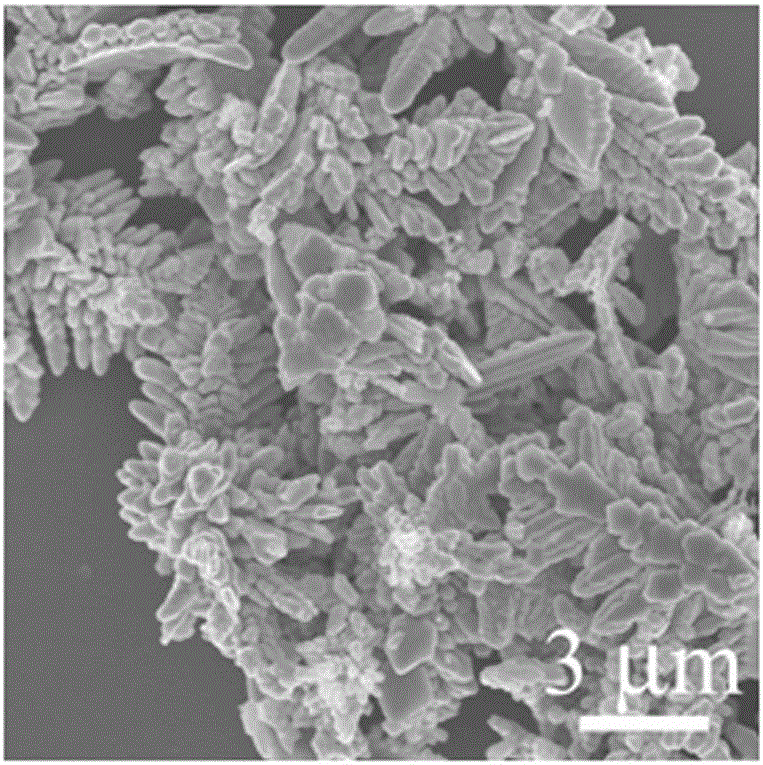

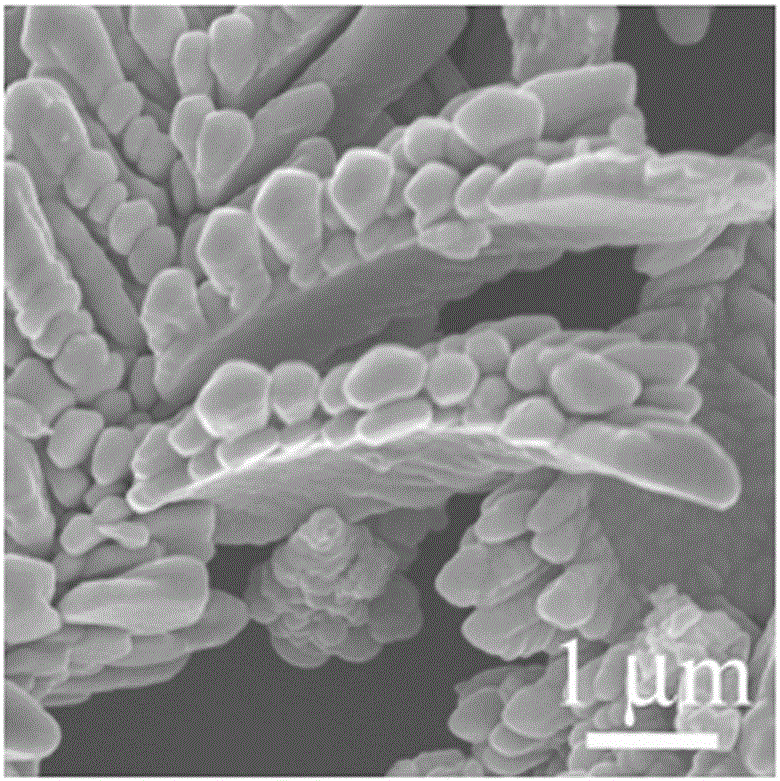

Method for prepring three-dimensional dendritic magnetic cobalt nano material through self-assembly of two-dimensional lamellar constitutional units

A magnetic metal and dendritic technology, applied in the field of microwave absorbing materials, can solve the problems of unreported application and achieve the effects of good experimental repeatability, simple preparation process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The two-dimensional sheet-like constituent units are self-assembled into a three-dimensional dendritic magnetic metal cobalt nanomaterial, and the preparation steps are as follows.

[0028] (1) Dissolve cobalt chloride hexahydrate in distilled water at room temperature to prepare a 0.03mol / L solution of cobalt chloride hexahydrate.

[0029] (2) Dissolve sodium hydroxide in distilled water at room temperature to prepare a 0.4mol / L sodium hydroxide solution.

[0030] (3) Add the solution of step (2) into the solution of step (1) and mix well.

[0031] (4) Add pyromellitic acid and sodium hypophosphite to the solution in step (3) and mix thoroughly. The concentration of pyromellitic acid is 0.05mol / L, and the concentration of sodium hypophosphite is 0.8mol / L.

[0032] (5) The solution of step (4) is loaded into the hydrothermal reaction kettle, and at 110 o C temperature reaction 24h. The product is washed with deionized water and absolute ethanol in sequence, and then...

Embodiment 2

[0036] The difference from Example 1 is that the concentration of pyromellitic acid is 0.015 mol / L. Microstructure such as Figure 7 shown.

Embodiment 3

[0038] The difference from Example 1 is: hydrothermal treatment for 8h. Microstructure such as Figure 8 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com