Production process for controlling generation of ozonized bromate

A technology for ozonating bromate and production process, which is applied in the field of water treatment, can solve the problems of low bromate generation efficiency, achieve low cost, improve treatment effect, and reduce concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

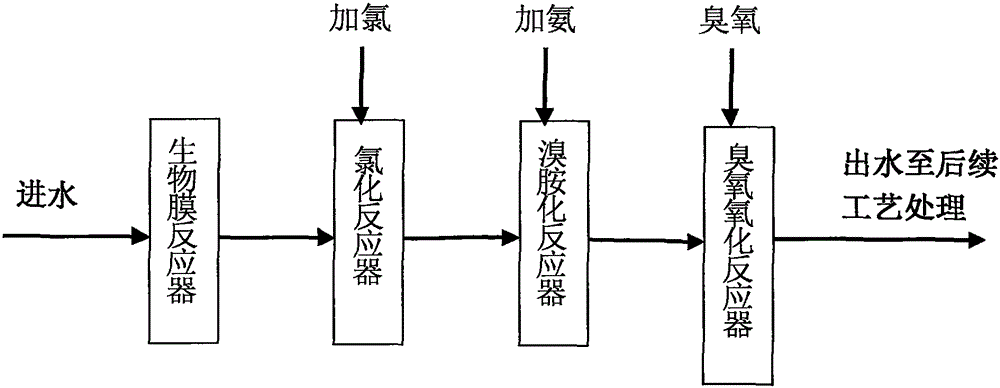

Method used

Image

Examples

Embodiment approach 1

[0026] After the water sample is first passed through the aerobic biofilm reactor to remove ammonia nitrogen, the bromide ion concentration in the water is 0.44mg / L, the DOC is 7.03mg / L, and the pH is 8.37. Take 3L of the water sample and put it into a 5L plastic bucket with a stirrer , add sodium hypochlorite to make the concentration of hypochlorous acid in the reactor 0.5mg / L, stir and react for 5min, then add ammonium chloride to make the concentration of ammonia nitrogen 0.7mg / L, stir and react for 1min, then add the water sample to the glass for ozone reaction In the device (the ozone reactor is cylindrical, with an inner diameter of 50mm, a height of 2m, and a microporous titanium plate aeration head at the bottom), the ozone gas generated by the ozone generator is sent to the ozone reactor through the microporous titanium plate aeration head. Water sample dosing, ozone dosing time is 20min, ozone dosing amount is 18mg / L.

Embodiment approach 2

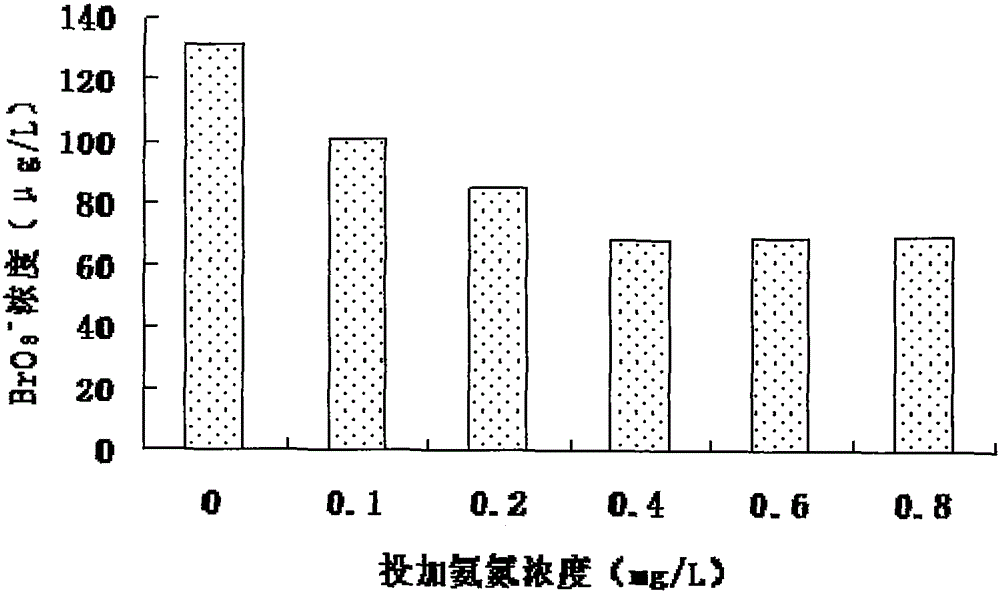

[0040]Adopt 5 kinds of water samples of different water quality, observe the adaptability of this method to water quality, test method is the same as embodiment 1. Each water sample was first passed through an aerobic biofilm reactor to remove ammonia nitrogen, and the concentration of bromate produced by a separate ozone oxidation process and the bromate produced by a chlorination / bromination / ozonation process were respectively, as shown in Figure 6 .

[0041] The water quality of the five water samples is different. After the ammonia nitrogen is removed by the aerobic biofilm reactor, each water sample is added with a concentration of 0.7 mg / L of HOCl and a concentration of 0.6 mg / L of ammonia nitrogen, and then the bromine produced by ozone is added. Salt concentration (ozone dosage 18mg / L, ozone oxidation reaction time 15min);

[0042] It can be seen that the 5 kinds of water samples with different water quality were firstly treated by aerobic biofilm reactor to remove a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com