Nanometer material used for photothermal therapy and preparation method thereof

A technology of nanomaterials and photothermal therapy, which is applied in the direction of nanotechnology, nanotechnology, and nanotechnology for materials and surface science. It can solve problems affecting photothermal conversion efficiency and achieve high photothermal conversion efficiency and photothermal treatment. High conversion efficiency and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

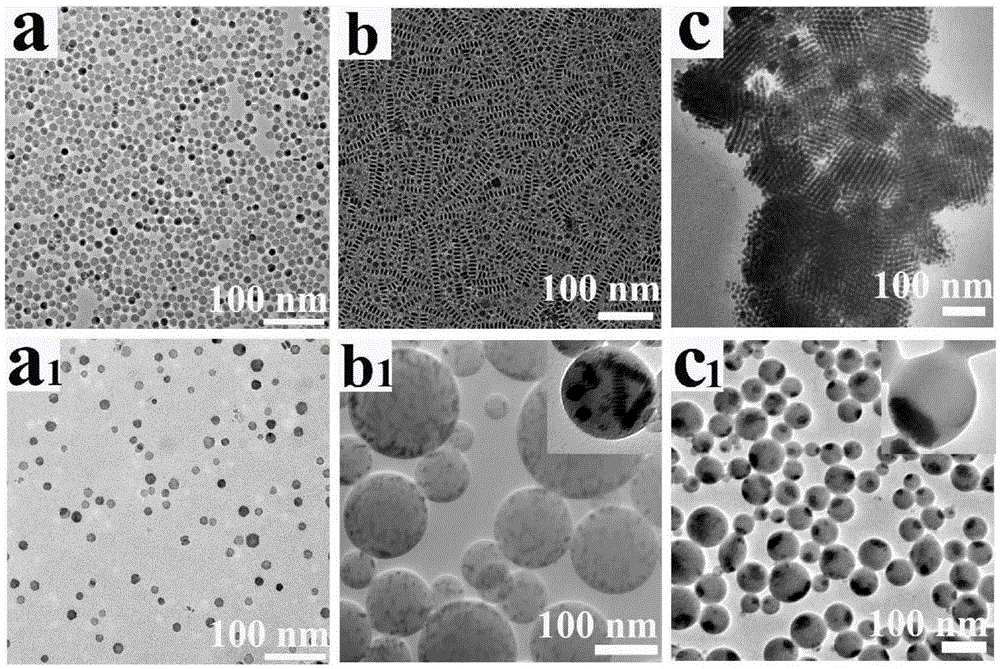

Embodiment 1

[0022] a. Mix 6ml of oleylamine (OAM), 4ml of octadecene (ODE) and 0.08ml of dodecanethiol (DDT) and stir slowly, and inject 15mg of Cu(S 2 CNBut 2 ) precursor, kept at 190°C for 10min;

[0023] b. After the reaction is naturally cooled, take out the reaction solution and centrifuge (15000 rpm) for 10min to obtain hydrophobic Cu 7 S 4 nanocrystals, then dispersed in 1ml chloroform;

[0024] c. Add 30mgPSI to 10mL10mM NaOH aqueous solution OAm and 1 mg hydrophobic Cu 7 S 4 Chloroform dispersion of nanocrystals, ultrasonic (500W, 6 minutes);

[0025] d. Stir at 60° C. for 2 hours to distill off the chloroform, centrifuge (12000 rpm) for 10 minutes to obtain sheet-shaped photothermally treated nanomaterials, and redisperse them in 2 ml of deionized water.

Embodiment 2

[0027] a. Mix 4ml oleylamine (OAM), 6ml octadecene (ODE), 13mg thioacetamide (TA) and 0.1ml dodecanethiol (DDT) and stir slowly, inject 15mg of Cu(S 2 CNBut 2 ) precursor, kept at 145°C for 60min;

[0028] b. After the reaction is naturally cooled, take out the reaction solution and centrifuge (15000 rpm) for 10min to obtain hydrophobic Cu 7 S 4 nanocrystals, then dispersed in 1ml chloroform;

[0029] c. Add 40mgPSI to 10mL0.5mM NaOH aqueous solution OAm and 1 mg hydrophobic Cu 7 S 4 Chloroform solution of nanocrystals, ultrasonic (500W, 6 minutes);

[0030] d. Stir at 60°C for 2h and distill off the chloroform. Centrifuge (12000 rpm) for 10 minutes to obtain hydrophilic nanocrystals and rod-shaped photothermally treated nanomaterials, which are redispersed in 2 ml of deionized water.

Embodiment 3

[0032]a. Mix 6ml of oleylamine (OAM), 4ml of octadecene (ODE), 75mg of thioacetamide (TA) and 0.4ml of dodecanethiol (DDT) and stir slowly, and inject 15mg of Cu(S 2 CNBut 2 ) precursor, kept at 190°C for 60min.

[0033] b. After the reaction is naturally cooled, take out the reaction solution and centrifuge (15000 rpm) for 10min to obtain hydrophobic Cu 7 S 4 nanocrystals, then dispersed in 1ml chloroform;

[0034] c. Add 30mgPSI to 10mL0.5mM NaOH aqueous solution OAm and 2 mg of hydrophobic Cu 7 S 4 Chloroform solution of nanocrystals, ultrasonic (500W, 6 minutes);

[0035] d. Stir at 60° C. for 2 hours to distill off the chloroform, centrifuge (12000 rpm) for 10 minutes to obtain hydrophilic nanocrystals, and obtain superlattice photothermally treated nanomaterials, which are redispersed in 2 ml of deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com